- Innovative new flotation system that requires no springs and minimises soil compaction

- With more blades and a cutting width up to 3.5 m

- Choice of two rotor speeds (780 or 1000 rpm) and easily adjustable conditioning flaps so you can quickly adapt your performance for any forage types

- Streamlined design to improve visibility

Features

Use front hitch for maximum productivity

Tractor hookup

Hookup

HookupThe F310R and F350R Front-Mounted Mower-Conditioners are used to maximize the potential of the 7R or 8R Tractor equipped with a front power take-off (PTO) and front hitch. This 1000-rpm mower-conditioner can be combined with the following 1000 rpm mower-conditioners to increase productivity:

- Side-pull mower-conditioner

- Side-mounted mower-conditioner

- Center-pivot mower-conditioner

- Twin rear-mounted mower-conditioner

With the new twin rear-mounted mower-conditioner, R870R, R950R and R990R unmatched productivity is gained with cutting width from 8.7 m (28.5 ft) up to 9.9 m (32.5 ft) in one pass.

Downstop chains are included for use with tractors, without front hitch position sensing. During mowing operation the front linkage is on a floating position in order to allow better ground following. The machine is sitting on stop chains as a reset down position. A front chain support kit (RE327692) is required to connect the down stop chains on a 8R tractor.

Hydraulic cylinders are used to raise and lower the cutting platform when crossing headlands.

- Front tractor hitch is not used to raise and lower the cutting platform

- Uses single-acting selective control valve (SCV) to raise platform.

- Lift cylinder operation must be independent of the front hitch operation.

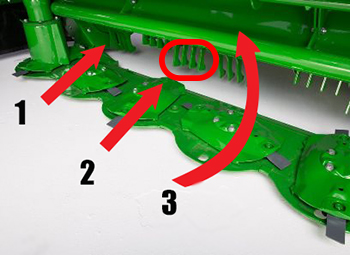

A perfect and fast cut with the rotary disc cutterbar

The 3.5-m (11.5-ft) wide cutterbar

The 3.5-m (11.5-ft) wide cutterbarPower is transmitted from the 1000-rpm power take-off (PTO) on the front of tractor through gearcases to the cutterbar.

- Standard position for main gearcase utilizes clockwise (as determined by direction of travel) rotation of the front PTO.

- Gearcase can be reversed for use with tractors with a counterclockwise (as determined by direction of travel) front PTO

- Cutterbar is protected by a slip clutch and overrunning clutch

- Cutterbar is securely mounted within the frame for strength and durability

Power is transmitted to the rotary disks through fully enclosed gears, running in oil, for quiet, smooth, reliable operation

- To meet serviceability, the cutting bed is lubricated for life: no oil changes necessary

- The high-speed rotary disks cut in the toughest conditions. The disks rotate at 2986 rpm.

- All disks are offering an orbital cutting diameter of 440 mm (17.3 in.).

- Low-profile design enables cutting close to the ground at a flat angle helping prevent damage to the disks and knives.

- Pinion gear is easily removed from the top of the cutterbar for service

- Idler gears can be removed from access area after removal of pinion gear

Quick knives exchange cutterbar

Quick knives exchange special tool

Quick knives exchange special tool QKE tool with knives box

QKE tool with knives boxA cutterbar has been developed to increase productivity through a significant down-time reduction when changing knives. Needed time drop down from three minutes per knife to about seconds. It is an efficient way to save up to 40 minutes of maintenance time on a F350R mower-conditioner.

All discs are offering an orbital cutting diameter of 440 mm (17.3 in.) The F310R is fitted with seven disks and the F350R with eight discs. The operator only needs to insert the special tool (attached to the mower-conditioner) between the disc and spring blade, push it down and remove the knife. No parts are lost during the change process.

Operator comfort is even further enhanced since knives used on the QKE cutterbar are designed to provide nearly the same cutting height as the classic cutterbar at 35 mm (1.4 in.). These knives, with a double cutting face, are the only to guarantee excellent cutting quality and efficient use with the QKE cutterbar (no crop accumulation, easy come back to cutting position).

Turnbuckle adjustment

Turnbuckle adjustmentCutting height is adjusted by changing the turnbuckle on the front hitch. Cutting range is from 35 mm to 85 mm (1.4 in. to 3.3 in.).

Conditioning and swath delivery

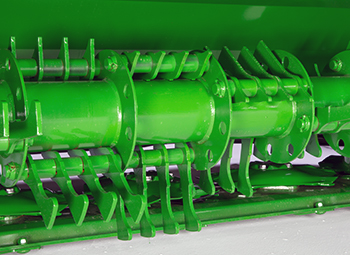

Impeller conditioner

Impeller conditioner Conditioner

ConditionerProducers need to be reactive to weather conditions when harvest is ready. They must cut faster, with efficient conditioning using swathing or wide spread.

The steel fingers provide the right impact on the plant, to remove the waxy coat.

The F310R is equipped with four tines in V-shaped on both sides of the conditioner and 76 straights.

The F350R is equipped with four tines in V-shaped on both sides of the conditioner and 100 straights.

This accelerates the drying process while requiring only little maintenance.

To improve productivity:

Five conditioning positions are available with two rotation speeds of 755 or 1000 RPM.

Speed change is done by a simple selector on the gear box.

The desired swath size can easily be obtained with adjustable swath deflectors:

- From 1.2 to 2.4 m (3.9 to 7.9 ft) on the F310R and F350R

- From 1.3 to 3.2 m (4.3 to 10.5 ft) on the R870R, R950R, and R990R

- Wide spread is available on all machines when very fast drying is required

Proper conditioning in a wide range of crops can be achieved when the conditioner is properly adjusted.

The impeller is not designed to condition leguminous, however if it has to, choose to light conditioning effect with the 755 rpm rotation speed and the conditioner adjustment lever on the minimum position.

Conditioner adjustment

Conditioner adjustmentProper conditioning in a wide range of crops can be achieved when the conditioner is properly adjusted.

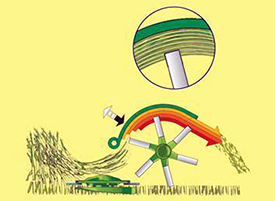

How an impeller conditioner works:

Conditioning effect

Conditioning effectAs hay is cut by rotating knives, tines pick up the plants and carry them through the machine: Tines are free swinging to reduce damage to the conditioner if rocks or other solid objects are struck.

As the plant passes through, it rubs against the conditioning hood and other plants: Scuffing action removes the waxy surface from the stem of the plant to allow faster evaporation of moisture.

The pivot point for the conditioning hood is also adjustable to provide a wider range of conditioning intensity.

The speed at which the tines rotate will also affect the degree of conditioning.

Two impeller speeds can be achieved by moving the speed selector on the gearbox. High speed will give an efficient conditioning while the lower speed. Will give a lighter conditioning.

With the selector on the rabbit position the impeller turns at 1000 rpm. If the selector is on the turtle position, the impeller turns at 755 rpm.

Rolls conditioning

Square flex conditioning rolls

Square flex conditioning rollsSquare flex conditioning rolls are ideal for alfalfa, but also for heavy forage like sorghum or grasses such as oats or sudan grass. The large, 24-cm (9.45-in.) diameter provides a good throughput capacity and ensures smooth material flow without material sticking to the rolls.

Conditioning pressure can be adjusted up to 500 kg/m (336 lb/ft) by rotating a central adjusting screw placed on the torsion bars. This provides a wide range for conditioning pressure.

The double animated rolls are directly driven by maintenance-free double transmissions. This allows for synchronization between the two rolls to never need adjustment.

Square flex conditioning rolls are only available on the F310R and the R950R Mower Conditioners.

Mower conditioners with square flex conditioning rolls

Mower conditioners with square flex conditioning rollsWindrowing solutions to match any needs

Windrow to match needs

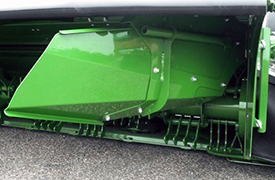

Windrow to match needsThe available room for a windrow is a function of wheel spacing and tire width. The windrow width of the F310R and F350R Front-Mounted Mower-Conditioner may be narrower than the windrows from a Twin Rear-Mounted Mower-Conditioner if the forming shields are adjusted so the tractor does not drive on the windrow that is produced.

Front-mount mower-conditioner windrow formation

Windrow

Windrow Front mower-conditioner adjustment

Front mower-conditioner adjustmentThe desired swath width can easily be obtained by loosening the handle on each side and moving the adjustable swath deflectors to the desired position. Swath width is adjustable from 1.2 m to 2.4 m (3.9 to 7.9 ft) for the F310R and F350R.

Rear-mount mower-conditioner windrow formation

Windrow forming shields (rear curtain raised for visibility)

Windrow forming shields (rear curtain raised for visibility) Adjustment handle

Adjustment handleForming shields are easily adjusted to control material flow. This allows the operator to match the windrow width to harvesting requirements.

The forming shields are easily adjusted to match harvest requirements. No tools are required to adjust the forming shields. Windrow width on each unit can be adjusted from 1.3 to 3.2 m (4.3 ft. to 10.5 ft).

Wide spread is available on all machines when very fast drying is required. The bundle consists of vanes that are installed behind the conditioning hood. The windrow width when using the widespread kit can be adjusted to be approximately the same as the cutting width of the platform.