- 18.4 kW (24.7 hp) liquid-cooled diesel engine

- ComfortGlide™ Suspension on all seat options

- Michelin® X® Tweel® Turf airless tyre option available

- 7-Iron PRO Deck available in 137cm (54 in.), 152cm (60 in.), and 152 cm (60 in.) Mulch On Demand™; 152cm (60 in.) and 183cm (72 in.) Rear discharge options

Features

Powerful 18.4-kW (24.7-hp) diesel engine delivers superior performance and efficiency

3-cylinder diesel engine

3-cylinder diesel engine Access to engine service points

Access to engine service pointsThe Z994R is powered by a 3-cylinder, liquid-cooled diesel engine with gross SAE J1995, PS 18.4 kW (24.7 hp) rated power at 3200 rpm that meets U.S. Environmental Protection Agency (EPA) Final Tier 4 emission standards:

- High-torque, low-emission diesel engine for strong performance in the toughest conditions

- Low vibration and noise levels

- Isolated with rubber mounts for a smoother operator ride

- Superior fuel economy

- High torque reserve for plenty of power and performance

Key features of the engine include:

- Economical, cast-in block cylinder design provides good cooling and long life.

- Liquid-cooled design provides more consistent operating temperatures than air-cooled.

- Fuel filter with replaceable element is provided.

- Indirect fuel injection uses a pre-combustion chamber to give the engine smooth and quiet operation.

- Full-pressure lubrication with full-flow filter lengthens engine life.

- Engine wear reduced by ensuring proper lubrication, even when operating on hillsides or uneven terrain.

- Oil filter helps keep oil clean for increased engine life.

- Aluminum alloy pistons with built-in steel struts are lightweight to reduce connection rod bearing loads and provide good heat-transfer characteristics.

- Design permits tighter tolerances and neutralizes expansion of the piston, thereby reducing blow-by fuel and noise from the piston slap.

- Higher top rings on the piston and a thinner head gasket greatly reduce the volume of unburned waste and increase combustion efficiency.

- Timing gears and injector drive gears utilize helical profile gears to help lower engine noise.

- Gear teeth have a ''roll-off'' profile, giving almost no clash, no noise, and no backlash.

- Glow plugs provide quick starts in temperatures down to -18°C (0°F)

- Key start and shutoff eliminate fuel shut-off knob; electric solenoid shuts fuel supply off immediately when key is turned off.

Air cleaner with secondary safety element and restriction indicator

Heavy-duty air cleaner

Heavy-duty air cleaner Air cleaner restriction indicator

Air cleaner restriction indicator- Dual-element, dry-type air cleaner with safety element and air service indicator

- Dual-element design for added engine protection and easy service

- Completely sealed for effective cleaning

- Ninety to 95 percent of dirt ejected before it reaches the paper element

- Air cleaner restriction indicator to let operator know when the filter needs servicing

Radiator

Radiator cover

Radiator cover Radiator cover knob

Radiator cover knobA sealed radiator compartment controls trash and debris. A cover is provided over the radiator, and a cooling fan area controls the flow of air.

Knobs on both ends of the cover hold it in place.

Radiator shown with debris screen removed

Radiator shown with debris screen removed Radiator and electric cooling fan

Radiator and electric cooling fanAn automotive-type radiator, coolant reservoir, and electric cooling fan are provided to remove heat from the engine coolant:

- The cooling fan is thermostatically controlled so it only runs when necessary.

- See-through coolant recovery tank permits the operator to check the coolant level without removing the radiator cap.

Radiator debris screen

Radiator debris screen Close-up of radiator debris screen

Close-up of radiator debris screenA debris screen with a corrugated shape to give a large surface area covers the intake air side of the radiator to keep the radiator fins clean.

The debris screen can be easily removed for cleaning, if desired, and also for access to the radiator fins.

Fuel tank

Fuel tank and angled fuel filler cap

Fuel tank and angled fuel filler cap Diesel fuel cap and fuel gauge

Diesel fuel cap and fuel gaugeThe Z994R Diesel ZTrak™ Mower is equipped with a single 43.5-L (11.5-U.S. gal.) fuel tank that provides enough capacity to allow mowing for a full day without refueling:

- Large, angled filler neck makes for easier refueling

- Fuel cap tether is provided to secure the filler cap while refueling

- Fuel gauge is provided as standard equipment

NOTE: The fuel fill level is 25 mm (1 in.) below the bottom of the filler neck.

Gearbox cooling fins and fan

Cooling fins and fan for right-angle gearbox

Cooling fins and fan for right-angle gearboxA right-angle gearbox is used to convert power from the horizontal shaft diesel engine to vertical shaft power to operate the vehicle transmission and the mower power-take off clutch. Cooling for the gearbox is provided by fins on the gearbox housing and a fan.

Three 7-Iron™ PRO Side-Discharge Mower Deck options give superior performance in every application

Z994R with fully adjustable suspension seat option and 72-in. (183-cm) mower deck

Z994R with fully adjustable suspension seat option and 72-in. (183-cm) mower deckThere are three side-discharge mower-deck options available for the Z994R Diesel ZTrak™ Mower:

- The 60-in. (152-cm) 7-Iron PRO Side-Discharge Mower Deck is suited to a variety of mowing jobs, including trimming and grooming.

- The 60-in. (152-cm) 7-Iron PRO Mulch On Demand™ Mower Deck can be converted from a wide-open, side-discharge mode to a fully chambered mulching mode with a single move of a lever.

- The 72-in. (183-cm) 7-Iron PRO Side-Discharge Mower Deck is suited to a variety of mowing jobs, including trimming and grooming.

Extra reliability and long life with cast-iron blade spindle housings

Cast-iron mower spindle

Cast-iron mower spindle Cast-iron mower spindle

Cast-iron mower spindleOn every commercial mower deck there are three 25-mm (1-in.) spindles that are cold-forged and heat-treated for strength. Spindles are supported by precision ball bearings that provide great performance and reliability.

- Superior impact strength provided by ductile cast-iron material.

- Gusseted design puts reinforcement where it is needed.

- Strength of cast iron protects against damage from blade impacts.

- Easy access grease fittings are mounted at the top of the spindle shafts for convenience.

- Grease pressure-relief valve minimizes seal damage from overfilling with grease and keeps debris from entering housing.

- Chance of deck shell damage is minimized with the 20.3-cm (8-in) diameter housing and six mounting bolts that distribute loads and impacts.

- Ability to be reliably rebuilt is provided by use of cast iron.

60-in. (152-cm) 7-Iron PRO Mower Deck

Similar 60-in. (152-cm) 7-Iron PRO Mower Deck shown

Similar 60-in. (152-cm) 7-Iron PRO Mower Deck shownFeatures include:

- Higher blade tip speed of approximately 5029 m/min (16,500 fpm) gives more blade strikes per distance of forward travel.

- The front baffle is designed to better manage airflow and control clippings.

- Spindle-pocket reinforcement provides even greater structural durability.

- A raised discharge chute allows for even clipping distribution.

- Thick, 7-gauge, 4.55-mm (0.179-in.) steel construction gives commercial durability.

- The three-spindle design provides a smooth, even cut.

- The trim edge of the deck is equipped with a bumper that provides great abrasion resistance to protect the machine and the property.

- A plastic discharge deflector reduces damage to foliage and resists bending.

- The formed, steel-deck design is forged from a single sheet of steel to eliminate corners where grass can collect.

- The deep deck gives increased vacuum action that reduces dropped clippings.

- The belt drive efficiently transfers power from gearbox to spindles.

- Spindle grease fittings are on top for easy access.

- Quick-change cutting-height adjustment is easy to use.

- Blade overlap of 40 mm (1.57 in.) reduces the number of missed grass blades.

- A mulching attachment is available.

- The Power Flow rear material collection system is available.

- Quick release belt covers for added convenience

60-in. (152-cm) 7-Iron PRO Mulch On Demand Mower Deck

60-in. (152-cm) 7-Iron PRO Mulch On Demand Mower Deck (shown on Z997R)

60-in. (152-cm) 7-Iron PRO Mulch On Demand Mower Deck (shown on Z997R) Mulch On Demand control lever (shown on Z997R)

Mulch On Demand control lever (shown on Z997R)Features include:

- The deck can be converted from a wide-open side discharge mode to a fully chambered mulching mode with a single move of a lever.

Higher blade tip speed of approximately 5029 m/min (16,500 fpm) gives more blade strikes per distance of forward travel.

- The front baffle is designed to better manage airflow and control clippings.

- Spindle-pocket reinforcement provides even greater structural durability.

- A raised discharge chute allows for even clipping distribution.

- Thick, 7-gauge, 4.55-mm (0.179-in.) steel construction gives commercial durability.

- The three-spindle design provides a smooth, even cut.

- The trim edge of the deck is equipped with a bumper that provides great abrasion resistance to protect the machine and the property.

- A plastic discharge deflector reduces damage to foliage and resists bending.

- The formed, steel-deck design is forged from a single sheet of steel to eliminate corners where grass can collect.

- The deep deck gives increased vacuum action that reduces dropped clippings.

- The belt drive efficiently transfers power from gearbox to spindles.

- Spindle grease fittings are on top for easy access.

- Quick-change cutting-height adjustment is easy to use.

- Blade overlap of 40 mm (1.57 in.) reduces the number of missed grass blades.

- The mulching attachment is available.

- The Power Flow rear material collection system is available.

- Quick release belt covers for added convenience

72-in. (183-cm) 7-Iron PRO Mower Deck

72-in. (183-cm) 7-Iron PRO mower shown on Z997R

72-in. (183-cm) 7-Iron PRO mower shown on Z997RFeatures include:

- Higher blade tip speed of approximately 5029 m/min (16,500 fpm) gives more blade strikes per distance of forward travel.

- The front baffle is designed to better manage airflow and control clippings.

- Spindle-pocket reinforcement provides even greater structural durability.

- A raised discharge chute allows for even clipping distribution.

- Thick, 7-gauge, 4.55-mm (0.179-in.) steel construction gives commercial durability.

- The three-spindle design provides a smooth, even cut.

- The trim edge of the deck is equipped with a bumper that provides great abrasion resistance to protect the machine and the property.

- A plastic discharge deflector reduces damage to foliage and resists bending.

- The formed, steel-deck design is forged from a single sheet of steel to eliminate corners where grass can collect.

- The deep deck gives increased vacuum action that reduces dropped clippings.

- The belt drive efficiently transfers power from gearbox to spindles.

- Spindle grease fittings are on top for easy access.

- Quick-change cutting-height adjustment is easy to use.

- Blade overlap of 40 mm (1.57 in.) reduces the number of missed grass blades.

- A mulching attachment is available.

- The Power Flow rear material collection system is available.

- Quick release belt covers for added convenience

Side-discharge mower deck specifications

| 60-in. (152-cm) | 60-in. (152-cm) | 72-in. (183-cm) Side-Discharge |

Mower type | 7-Iron PRO - forged deck | 7-Iron PRO - forged deck | 7-Iron PRO - forged deck |

Mower compatibility: |

|

|

|

Discharge | Side | Side | Side |

Mulching | Optional field-installed kit | Standard Mulch On Demand included | Optional field-installed kit |

Cut-height | 3.8-12.7 cm (1.5-5 in.) in 6.35 mm (0.25-in.) increments | 3.8-12.7 cm (1.5-5 in.) in 6.35 mm (0.25 in.) increments | 3.8-12.7 cm (1.5-5 in.) in 6.35 mm (0.25 in.) increments |

Cutting width | 152 cm (60 in.) | 152 cm (60 in.) | 183 cm (72 in.) |

Height-of-cut | Turning knob with foot pedal lift | Turning knob with foot pedal lift | Turning knob with foot pedal lift |

High lift blades: |

|

|

|

Blade length | 53 cm (21 in.) | 53 cm (21 in.) | 63 cm (25 in.) |

Blade width | 7.6 cm (3 in.) | 7.6 cm (3 in.) | 7.6 cm (3 in.) |

Blade thickness | 6.35 Mm (0.25 in.) | 6.35 Mm (0.25 in.) | 6.35 Mm (0.25 in.) |

Blade tip speed | Approximately 5,029 m/min (16,500 fpm) | Approximately 5,029 m/min (16,500 fpm) | Approximately 5,029 m/min (16,500 fpm) |

Number of | Three | Three | Three |

Blade spindles: |

|

|

|

Bearings | Grade=ABEC-1 | Grade=ABEC-1 | Grade=ABEC-1 |

Spindles | Cold-forged and heat-treated | Cold-forged and heat-treated | Cold-forged and heat-treated |

Spindle | Cast iron | Cast iron | Cast iron |

Wheels: |

|

|

|

Front anti-scalp | Standard | Standard | Standard |

Rear anti-scalp rollers | Standard | Standard | Standard |

Deck construction | One-piece forged steel | One-piece forged steel | One-piece forged steel |

Deck thickness | 7-gauge steel, 4.55 mm (0.179 in.) | 7-gauge steel, 4.55 mm (0.179 in.) | 7-gauge steel, 4.55 mm (0.179 in.) |

Optional three-bag material collection system (MCS)

Three-bag MCS

Three-bag MCS Standard weight bracket and weights, for three-bag MCS

Standard weight bracket and weights, for three-bag MCSThe 493-L (14-bu), three-bag MCS is available for the Z994R with a 60-in. (152-cm) Mower Deck, or a 60-in. (152-cm) Mulch On Demand Mower Deck. Professional landscape contractors can increase productivity by utilizing this durable collection system. This system allows fast, easy grass clipping and leaf collection to give lawns a well-groomed appearance.

Optional dump-from-seat material collection system

Dump-from-seat MCS

Dump-from-seat MCS Standard weight bracket and weights, for dump-from-seat MCS

Standard weight bracket and weights, for dump-from-seat MCSThe durable dump-from-seat MCS for the Z994R ZTrak Mower increases productivity. Professional landscape contractors are able to empty the large, 458-L (13-bu) capacity hopper without leaving the seat. This system allows fast, easy grass clipping and leaf collection to give lawns a well-groomed appearance.

Optional Power Flow blower

Power Flow blower

Power Flow blower Power Flow blower in cleanout position

Power Flow blower in cleanout positionA Power Flow blower is required (ordered separately) for use of a three-bag or dump-from-seat MCS.

The Power Flow blower can be opened for easy and thorough cleanout.

Enhanced productivity, safety, and trim ability with a FastBack™ PRO rear-discharge mower deck

60-in. (152-cm) Rear-Discharge Mower Deck

60-in. (152-cm) Rear-Discharge Mower Deck 72-in. (183-cm) Rear-Discharge Mower Deck

72-in. (183-cm) Rear-Discharge Mower DeckFor professional landscapers and government municipalities requiring rear discharge placement of grass and debris, John Deere FastBack PRO rear-discharge mower decks deliver a commercial zero-turn mowing solution for both gas and diesel machines. Advantages of a rear-discharge mower include:

- Less chance of damage from objects being thrown from the mower deck

- Time savings with the ability to mow closely around fixed objects with either side of the deck

- A cleaner mowing experience by lessening the amount of debris that can blow onto the operator

A rear-discharge mower deck is ideally suited for:

- Schools

- Parks

- Playgrounds

- Traffic areas (city boulevards, roadsides, etc.)

- Areas with long, grassy spots that need to be cut, where you are not as concerned about wide dispersal of grass (park areas, roadsides, etc.)*

*NOTE: Operators maintaining turf outside of target areas are encouraged to evaluate rear-discharge dispersion through a cut quality demonstration to ensure satisfaction.

Compatibility

Mower deck | Z930M | Z950M | Z960M | Z950R | Z970R | Z994R | Z997R |

60-in. (152-cm) FastBack PRO rear-discharge | x | x | x | x | x | ||

72-in. (183-cm) FastBack PRO rear-discharge | x | x | x | x | x |

Commercial-quality deck design

A large volume of material can be thoroughly processed with the deep-deck design:

- Unique baffling system is designed to reduce clumping and windrowing often associated with rear-discharge mowers.

- Efficiency is enhanced with baffles surrounding each blade to control material as it is moved to the rear.

- Material exits the deck quickly as the baffles are lower at the rear.

- Movement of material is controlled to minimize the likelihood that clippings are thrown onto unwanted areas.

- Less debris gets on the operator as material is directed to the rear and toward the ground.

- Debris is kept low and directed into the turf by the flexible rear shield.

Extra convenience

Serrated-tread step

Serrated-tread stepExtra convenience and security are provided by a serrated surface that is welded to the top left corner of the deck, providing additional traction when entering and exiting the operator station.

Level cut

Center deck rollers and left wheel

Center deck rollers and left wheel Right-rear deck wheel

Right-rear deck wheelThe deck is suspended from and supported by the machine to provide a level cut. Mower deck wheels and rollers help smooth out the mowing job in uneven conditions and reduce the chance of scalping the lawn:

- Two wide front rollers at the center of the mower support the deck when necessary to prevent scalping.

- Wheels at all four corners protect the deck from scalping at the sides of the mower.

- Continued effectiveness results from wheels and rollers that are double captured for extra strength, which reduces the chance of damage.

- Height of rollers and wheels is adjustable to suit mowing conditions.

- Higher setting (shown in images) are used when mowing at lower cut heights and for rougher conditions at all cut heights where you want to reduce the chance of the wheels hitting the ground.

- Lower settings are used for higher cut heights and for helping to smooth out the mowing job.

- Mower cut height is adjustable from 1 to 5.5 in. (2.54 to 14 cm) in 0.25-in. (0.64-cm) increments from the machine operator’s station.

Heavy-duty components for long life

Strong, reinforced deck

Strong, reinforced deck Right trim-side wear guard

Right trim-side wear guardThese rear-discharge decks are designed to stand up to heavy-duty commercial use:

- Superior strength and durability come from a 7-gauge, 0.179-in. (4.6-mm) steel deck.

- Experience extra strength and long life with a fabricated deck design that is formed, welded, and reinforced for extra protection from damage.

- The front of the deck is protected from damage by a 1.5-in. (3.8-cm) tall by 0.5-in. (1.3-cm) thick solid steel bar welded to the mower deck for additional strength.

- Both sides of the deck have bumpers that are made from compression molded ultra-high molecular weight (UHMW) polyethylene plastic.

- The bumpers provide great abrasion resistance to protect the machine and the property.

- Additional strength is provided by a 0.5-in. (1.3-cm) by 0.5-in. (1.3-cm) thick solid steel bar.

Universal joint and cast-iron gearbox (Z997R)

Universal joint and cast-iron gearbox (Z997R) Cast-iron blade-spindle housing

Cast-iron blade-spindle housingDurability is designed into the mower blade drive system:

- Reliably powered by a universal joint shaft drive from the vehicle transmission to a heavy-duty right-angle, cast-iron gearbox (Z997R)

- Dependable v-belt drive system

Extra reliability and long life are provided by cast-iron blade spindle housings:

- Ductile cast-iron material provides superior impact strength.

- Gusseted design puts reinforcement where it is needed.

- Strength of cast iron protects against damage from blade impacts.

- Grease pressure-relief valve minimizes seal damage from overfilling with grease and keeps debris from entering housing.

- Chance of deck-shell damage is minimized with the 8-in. (20.3-cm) diameter housing and six mounting bolts that distribute loads and impacts.

- Ability to be reliably rebuilt is provided by use of cast iron.

Ease of service

Quick-release belt cover

Quick-release belt cover Cast-iron spindle housing assembly

Cast-iron spindle housing assemblyMinimal service requirements increase uptime:

- Quick-release belt covers do not require tools or the removal of a ring clip; just lift one corner of the cover and rotate it slightly to remove.

- A hole in the deck tab is provided for use of an optional ring clip for extra security, if desired.

- This makes it quick and easy for you to clean out trash that may collect around the spindle sheave.

- Convenient spindle greasing with fittings at the top of spindle shafts are accessible through a hole in the top of the spindle/belt covers.

- The center spindle is accessed by no-tools removal of the vehicle floor pan.

- There is only one belt to service.

Exceptional operator comfort begins with a high-quality seat and suspension

High back suspension seat

High back suspension seatOperator comfort was a primary focus in the design of the Z994R:

- Large, open operator station and foot platform with plenty of legroom and room for multiple foot positions

- A choice of seat and suspension options to suit the operator and operating conditions

- Instruments, controls, and storage areas that are easy to see and use

- Three-position rollover protective structure (ROPS) and retractable seat belt for operator safety and convenience

- Thick seat cushion for lasting comfort, even after a full day of use

- Retractable seatbelt for convenience and ease of use

- Springs to isolate the seat base for increased ride comfort

ComfortGlide suspension with fore/aft control

ComfortGlide suspension with fore/aft control Seat easily raised with spring-loaded latch

Seat easily raised with spring-loaded latch- ComfortGlide fore/aft suspension for superior ride comfort over uneven areas

- Seat can travel up to 50.8 mm (2 in.) fore and aft to absorb bumps for a significant enhancement to ride comfort

- Ability to easily lock out if desired by the operator

- One lever for three functions

- Slide seat forward and back 7.6 cm (3 in.)

- Activate ComfortGlide fore/aft seat suspension

- Lock-out ComfortGlide fore/aft seat suspension

A spring-type locking mechanism holds the seat securely down in the operating position for operator comfort and safety, but allows quick release for tilting the seat up:

- For protection from the elements

- For access to the transmission fluid reserve tank, battery, etc.

Fully adjustable seat with 61-cm (24-in.) high back, armrests and ComfortGlide fore/aft suspension

Fully adjustable suspension seat with armrests and 61-cm (24-in.) high back

Fully adjustable suspension seat with armrests and 61-cm (24-in.) high back Armrest adjustment

Armrest adjustmentThe fully adjustable, 61-cm (24-in.) high-back, mechanical suspension seat with adjustable armrests includes:

- Adjustable armrests that can also be raised for operator convenience

Mechanical suspension seat adjustment

Mechanical suspension seat adjustment Lumbar adjustment lever

Lumbar adjustment lever- Suspension seat control dial for easy adjustment of suspension to suit the operator

- Adjustable lumbar support for operator preference

- Lumbar adjustment gives extra operator comfort

- Adjustment is especially helpful when operating the vehicle for extended periods of time

- Vibration reduction

- Seat back-angle adjustment to maximize operator comfort by using a convenient lever on the side of the seat

Foot pegs

Foot pegs available standard on R-spec Z900’s

Foot pegs available standard on R-spec Z900’sFoot pegs help provide the operator with a comfortable foot placement.

- Location and angle of foot pegs can be adjusted for individual operator comfort.

Foot platform isolators

Foot platform isolators

Foot platform isolatorsFoot platform isolators provide the operator with added comfort.

- Vibration to the legs and feet is reduced.

Onboard storage and cup holder

Onboard storage compartment

Onboard storage compartment Cup holder

Cup holderA convenient storage compartment and cup holder are available within easy reach of the operator.

Instruments and controls are easy to find and use

The contoured dash has clean, attractive styling:

- Controls are located on the right instrument panel for convenience

- Color coded and labeled for easy identification by the operator

- Controls are logically placed and easy to reach on the right-hand control panel

- Functional design of the controls provides good appearance and a comfortable feel

Right-hand control panel

Instrument panel

Instrument panel Hour meter, monitoring, and diagnostic display

Hour meter, monitoring, and diagnostic displayControls are grouped on the right console, providing one central location for key switch, engine speed control, power take-off (PTO) engagement, height-of-cut adjustment, hour meter, and engine diagnostics.

The comprehensive display tells when oil changes and other maintenance should be performed, monitors vehicle function, and helps diagnose common downtime issues:

- A service reminder feature will indicate that a general lubrication or mower/engine service interval has been reached.

- When service is required, arrows will periodically flash for two hours.

- Other features include:

- Hour meter

- Engine overheat warning light

- Battery/alternator warning light

- High transmission oil temperature warning light

- Glow plug on indicator light

- Maintenance needed indicator light

- Low engine oil pressure warning light

Foot pedal Brake & Go starting system and mower lift

Brake & Go pedal

Brake & Go pedal Mower lift pedal

Mower lift pedalThe Brake & Go starting system is a John Deere exclusive. This feature makes the starting process easier:

- The Brake & Go starting system is easy to understand and use.

- To start the machine, the parking brake must be engaged.

- It does not matter whether the PTO switch is on or off, nor does it matter if the control levers are pulled in or extended out.

- As long as the parking brake is engaged, the machine will start. When the parking brake is applied, the control levers cannot be moved.

- Park brake engagement returns motion-control levers to the neutral position.

A foot pedal is used to raise the mower deck to adjust cut height or lock the mower deck in the transport position:

- A foot pedal is easier for many operators to use than a hand lever.

- Adjustable spring assist allows fine-tuning lift effort to the mower and the operator.

Cut-height adjustment

Mower deck height adjustment knob

Mower deck height adjustment knob Transport lock knob

Transport lock knobAn easy-to-use height-of-cut adjustment lift system allows the operator to quickly adjust deck height for different mowing applications as well as transport:

- An easy-to-use cutting-height lift system allows the operator to adjust the mower deck height with no tools and minimal effort.

- The easy-to-grip knob allows operators to dial in the desired height of cut (HOC).

- Cutting height can be adjusted from approximately 2.5 cm to 14 cm (1 in. to 5.5 in.).

- Rotate the knob to adjust from 2.5 cm to 14 cm (1 in. to 5.5 in.) in 0.64 cm (0.25-in.) increments.

- Each increment on the knob adjusts the HOC approximately 0.64 cm (0.25 in.).

- The deck can also be raised and locked in a transport position to provide maximum ground clearance when moving the machine from one area to another.

The transport lock function allows the deck to be locked in the transport position and returned to the previous HOC.

- Use the foot-lift pedal to lift the deck, then engage the transport lock.

- To unlock and lower the deck, simply pull up on the transport unlock knob, adjust the dial, and release the deck lift assist pedal to lower the deck to the chosen height.

This design increases productivity by allowing operators to change the cutting height without having to leave the seat.

Motion-control levers

Motion-control levers in use

Motion-control levers in use Motion-control levers in park position

Motion-control levers in park positionTwo hydrostatic control levers are designed for operator comfort and control:

- Allow the operator to select the ground speed and direction simply by moving levers forward or reverse

- Positive neutral lock position for levers provides added safety

The wide-bend, large-diameter steering levers swing out easily for entry and exit from the operator platform.

Motion-control lever and tracking adjustments

Motion-control lever height and fore/aft adjustment bolts

Motion-control lever height and fore/aft adjustment bolts Motion-control lever gap (1) and tracking (2) adjustments

Motion-control lever gap (1) and tracking (2) adjustmentsMotion-control lever adjustments include:

- Two height positions to suit the operator.

- Control lever fore/aft position to suit operator size and preference.

- Slots in control levers allow forward/rearward adjustment of control arms when the bolts are loose.

- Gap between the control levers adjustment (1).

- From-the-seat tracking adjustment (2), operators can mow straight and produce professional striping results.

Serviceability features give convenience and maximize uptime

3-cylinder diesel engine

3-cylinder diesel engine Access to engine service points

Access to engine service pointsFrequently accessed service areas such as the air cleaner, radiator screen, and oil check and fill points can be easily accessed from the open engine compartment.

An easy-to-remove rear engine service panel allows access to all engine service points for scheduled service or other maintenance work.

Radiator coolant reservoir

Radiator coolant reservoir Engine oil filter, dipstick, and fuel filter/water separator

Engine oil filter, dipstick, and fuel filter/water separatorThe design of the Z994R makes service components like the engine oil dipstick, oil filter, and fuel filter/water separator easy to see and access:

- Large radiator coolant reservoir and fuel filter/separator reduce service requirements and increase uptime.

- A convenient fuel shutoff is provided on the filter/separator.

Removable floor panel

Removable floor panel Floor panel removed for mower access (similar Z970R shown)

Floor panel removed for mower access (similar Z970R shown)The floor panel is easily removed, without tools, to give access to the top of the mower deck for cleaning and service.

All mower deck blade spindle grease fittings can be accessed from the top of the mower deck.

Battery and transmission fluid reservoir access

Flip-up seat

Flip-up seat Service access with seat in raised position

Service access with seat in raised positionThe seat is locked down for operator comfort and safety, but the spring latch system is easily released to raise the seat to protect it from the elements and give access to the battery, transmission fluid reservoir, etc.

Battery

Battery Sealed fuse and relay box

Sealed fuse and relay box- Maintenance free, 600 cold-cranking amp (CCA) battery is provided for fast, reliable engine starts.

- Electrical box is sealed to keep dirt and moisture out for reliability and ease of service.

Motion-control lever and tracking adjustments

Motion-control lever two-position height adjustment

Motion-control lever two-position height adjustment Adjustments for fore-aft position (1) and tracking (2)

Adjustments for fore-aft position (1) and tracking (2)Motion-control lever adjustments include:

- Two height positions to suit the operator

- Control lever fore/aft position to suit operator size and preference

- Slots in control levers allow forward/rearward adjustment of control arms when the bolts are loose.

- Gap between the control levers adjustment (1)

- From-the-seat tracking adjustment (2) so operators can mow straight and produce professional striping results

Service information and diagnostics

Service information label

Service information label Digital multi-function display

Digital multi-function displayA digital multifunction display shows the number of hours the machine is run when the key switch is in the on position. It only counts the hours the engine is actually running. Monitoring systems to notify operators of machine status and quickly diagnose common downtime issues include:

- Glow plug monitor

- Maintenance required notification

- Low oil pressure

- Hour meter

- Coolant overheat notification

- Battery charging system

- High engine oil temperature

Quick response (QR) codes link to owner information web pages

QR code label

QR code label To speed access to owner information web pages, a QR code is printed onto a product identification number (PIN) label located under the right steering lever. The owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalogs

- Maintenance reminder sheets

- Attachments

- Warranty statements

Optional service jack kit and jack

Jack kit and jack installed

Jack kit and jack installed Jack in storage position

Jack in storage positionThe Z994R front frame member is pre-drilled to accept the optional jack kit and jack:

- The jack makes servicing the underside of the mower deck safer and easier.

- Placed in the storage position, the jack can be carried on the machine, always available for use.

- The jack will need to be removed when using front ballast that is required for a rear material collection system.

Three-year, 1500-hour bumper-to-bumper warranty

Z994R ZTrak™ Mower

Z994R ZTrak™ Mower Z994R ZTrak Mower

Z994R ZTrak MowerAn exclusive two-year, unlimited hour/three-year, 1500-hour (whichever comes first) bumper-to-bumper warranty is standard on the Z994R. The warranty is best in the industry and puts John Deere at the forefront of commercial mowing. It is also hassle free, with one company handling all of the paperwork.

NOTE: The warranty covers 36 months or 1500 hours, whichever comes first. For the first 24 months, there is no hour limitation.

Heavy-duty chassis components provide strength and durability

Z994R ZTrak™ Mower with optional dump-from-seat material collection system

Z994R ZTrak™ Mower with optional dump-from-seat material collection system Z994R ZTrak Mower

Z994R ZTrak MowerAttractive styling incorporates a roomy and uncluttered operator platform with adjustable footrest, seat, and steering control positions for different operator preferences. Other well-thought-out features further contribute to good looks and operator comfort.

The frame is made of heavy-duty formed and welded steel for strength and reliability.

Formed and welded steel frame

Z994R ZTrak Mower

Z994R ZTrak Mower Z994R ZTrak Mower

Z994R ZTrak MowerA strong, welded steel frame provides solid, reliable support for the machine components and operator:

- Heavy-duty, 7-gauge, 4.55-mm (0.179-in.) 38x76.2-mm (1.5x3-in.) steel tubular frame for durability

- Wide-open access for maintenance and cleaning

- Rear frame provides solid support and protection for the engine

Front axle and offset caster wheels

Front axle and caster wheels

Front axle and caster wheelsCast I-beam caster arm and spindle assemblies handle the beating and pounding professional mowers receive.

Caster wheels are offset for optimum steering and mowing performance. Benefits include better inside-corner trimming performance and less chance of between-blade striping.

Rear bumper provides protection

Z994R rear bumper

Z994R rear bumper Optional rear hitch

Optional rear hitchA steel rear bumper provides protection for the machine.

A rear hitch can be added to the steel bumper for towing purposes. The Z994R can tow up to 400 lb (181.4 kg).

Durable pump and wheel motor hydrostatic drive delivers speeds up to 18.3 km/h (11.4 mph)

Right angle gearbox with cooling fins and fan

Right angle gearbox with cooling fins and fan Illustration of unitized pump and wheel motor drives

Illustration of unitized pump and wheel motor drivesA right-angle gearbox is used to convert power from the horizontal shaft diesel engine to vertical shaft power to operate the vehicle transmission. Cooling for the gearbox is provided by fins on the gearbox housing and a fan.

The hydrostatic drive included with the Z994R features two 13-cc (0.8-cu in.) unitised hydraulic pumps combined with commercial-grade, heavy-duty, 13-cc (0.8-cu in.) wheel motors into a single unit. The drive units feature cross porting, where the hydraulic fluid from the side doing the least work is filtered and then fed into the input of the side doing the most work. This ensures that the coolest fluid is going into the side working the hardest in order to provide the best performance during extended hillside operation in the same direction.

One pump and motor drive assembly for each wheel provides the following benefits:

- Exceptional cooling, even in high-load conditions

- Easy-to-check level and refill hydraulic oil

- Opens up access under the seat

Transmission fluid tank fill cap

Transmission fluid tank fill cap Motion-control levers (shown in park position)

Motion-control levers (shown in park position)One transmission oil reservoir is used for both of the unitised transmissions.

Motion control levers are designed for operator comfort and ease of controlling vehicle speed and direction.

Motion-control lever height adjustment bolts

Motion-control lever height adjustment bolts Motion-control lever gap (1) and tracking (2) adjustments

Motion-control lever gap (1) and tracking (2) adjustmentsMotion-control lever adjustments include:

- Two height positions to suit the operator.

- Control lever fore/aft position to suit operator size and preference.

- Slots in control levers allow forward/rearward adjustment of control arms when the bolts are loose.

- Gap between the control levers adjustment (1).

- From-the-seat tracking adjustment (2), operators can mow straight and produce professional striping results.

Thoughtful designs and high-quality controls promote safe operation

Safety interlock systems

Brake & Go pedal

Brake & Go pedal Motion-control levers (shown in park position)

Motion-control levers (shown in park position)The Brake & Go starting system is a John Deere exclusive. This feature makes the starting process easier:

- The Brake & Go starting system is easy to understand and use.

- To start the machine, the parking brake must be engaged.

- It does not matter whether the power take-off (PTO) switch is on or off, nor does it matter if the control levers are pulled in or extended out.

- As long as the parking brake is engaged, the machine will start. When the parking brake is applied, the control levers cannot be moved.

- Brake & Go operator-presence system returns levers to the neutral position when the brake pedal is actively engaged.

Mower deck safety

60-in. (152-cm) Mower Deck

60-in. (152-cm) Mower DeckMower safety features include:

- A high-quality deflector that meets applicable safety standards and disperses cut grass

- Spindle-sheave shielding that protects and is easy to remove without tools for cleaning and service

- A substantial welded-on metal step on the mower deck for safer operator entry and exit from the machine

Mower decks are safety certified

Mowers decks are evaluated by the manufacturer (John Deere Turf Care) and conform to American Nation Standards Institute (ANSI) B71.4 2004 safety certification specifications for commercial turf care equipment.

Protective zone around the operator is provided by the rollover protective structure (ROPS)

Z994R with 72-in. (183-cm) mower deck

Z994R with 72-in. (183-cm) mower deckThe spacious operator station has been designed for comfort, visibility, and ease of use:

- Getting on and off is easy with the flat operator platform.

- Convenient-to-use controls located close to the operator are color coded and designed for easy identification and operation.

The ROPS and seat belt work in conjunction to provide a protective zone around the operator:

- It reduces the operator’s risk of being crushed under the vehicle should it overturn.

- When used with the seatbelt, the ROPS can reduce the severity of injury in the event of a rollover.

- Use of the seat belt is recommended when operating with ROPS in the upright position.

ROPS in upright position

ROPS in upright position ROPS in intermediate position

ROPS in intermediate positionFoldable ROPS and a retractable seat belt are standard equipment:

- Position adjustment pins provide a good grip and make changing the angle of the ROPS easier.

- If operating in low clearance areas, the ROPS can be folded and secured out of the way. It can also be positioned in an intermediate position to accommodate machines equipped with a material collection system.

- Under normal operation, the ROPS should be in the up position.

- See Operator’s Manual for more information on ROPS.

ROPS in down position (similar vehicle shown)

ROPS in down position (similar vehicle shown) Retractable seat belt

Retractable seat belt- Door height of most garages will accommodate the machine with ROPS in the full-raised position.

- Easy-fold ROPS improves the ability to store the ZTrak™ mower in structures with a lower door opening.

| ROPS position | Height at top of ROPS |

| Full height | 185 cm (73 in.) |

| Down | 119 cm (47 in.) |

Optional Light-emitting diode (LED) work lights

LED work lights

LED work lightsBUC11438 LED work lights are available as a field installed attachment. BUC11438 is compatible with model year 2015 and newer (serial number 030,001-) Z900 ZTrak Mowers. All Z997R and model year 2015-2018 (serial number 030,001-070,000) gasoline powered models require AUC18778 battery jumper.

Optional LED beacon light

LED beacon light

LED beacon lightBUC11406 LED beacon light is available as a field installed attachment. The beacon light is short to avoid damage. BUC11406 is compatible with model year 2015 and newer (serial number 030,001-) Z900 ZTrak Mowers. All Z997R and model year 2015-2018 (serial number 030,001-070,000) gasoline powered models require AUC18778 battery jumper.

Manage your commercial mowing fleet using John Deere Operations Center™

TerrainCut™ Front and Wide-Area Mowers

TerrainCut™ Front and Wide-Area MowersOverview

A JDLink™ M Modem - 4G connects a commercial mower to the John Deere Operations Center, which enables you to manage your fleet more efficiently, increase productivity, and reduce labor costs. With a modem and Operations Center, you are always connected to the work in progress and can make timely adjustments to keep your fleet mowing.

JDLink M Modem - 4G

JDLink M Modem - 4G

JDLink M Modem - 4G A JDLink M Modem - 4G is standard equipment on model year 2024 and newer TerrainCut Front and Wide-Area Mowers.

A modem can be field installed on:

- Model year 2024 and newer Z700 ZTrak™ Mowers

- Model year 2024 and newer gasoline-powered Z900 ZTrak Mowers

- Model year 2024 and newer Z994R ZTrak Mowers

- Model year 2024 and newer Q800 QuikTrak™ Mowers

- Model year 2022-2023 TerrainCut Front Mowers

- Model year 2023 TerrainCut Wide-Area Mowers

See compatibility section for serial number breaks and requirements.

John Deere Operations Center

John Deere Operations Center is available on PC, Apple iOS, and Android mobile apps

John Deere Operations Center is available on PC, Apple iOS, and Android mobile appsThe John Deere Operations Center tracks your fleet and provides tools to analyze mower data. The connected features vary by mower model.

Models | Location and status | GPS speed | Geofencing and curfews | Engine hours | Maintenance planner | Machine Analyzer Tool | Fuel level | Fuel consumption | Diagnostic trouble codes | Service Advisor Remote |

Z700 ZTrak Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

Gasoline-powered Z900 ZTrak Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

Z994R ZTrak Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

E Series QuikTrak Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

Q820M, Q850M, and Q850R QuikTrak Mowers | X | X | X | Sync | X | X | X | --- | X | --- |

Q865R EFI QuikTrak Mowers | X | X | X | Sync | X | X | X | X | X | X |

1550 TerrainCut Front Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

1570, 1575, 1580, and 1585 TerrainCut Front Mowers | X | X | X | Sync | X | X | --- | --- | X | X |

1600 TerrainCut Wide-Area Mowers | X | X | X | Sync | X | X | --- | --- | X | X |

Location and status

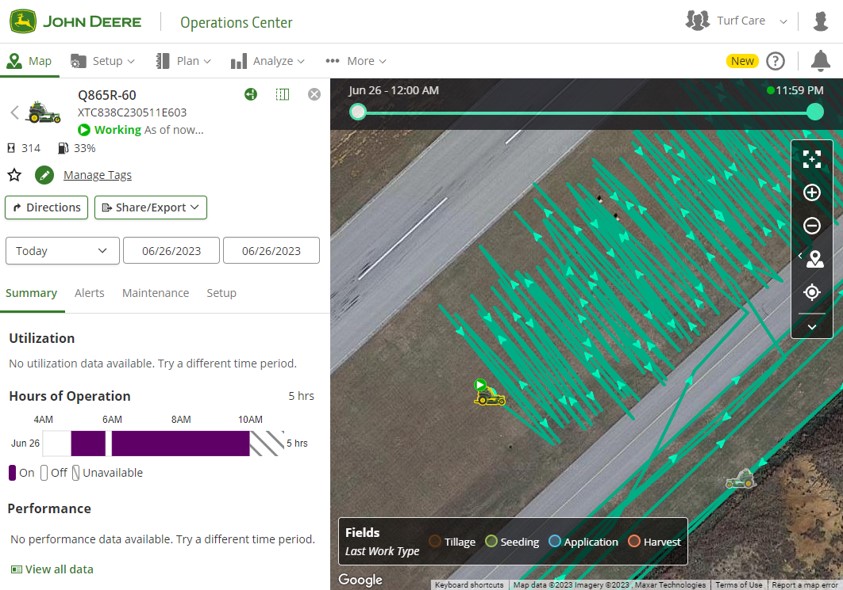

Operations Center map displaying past locations of a mower

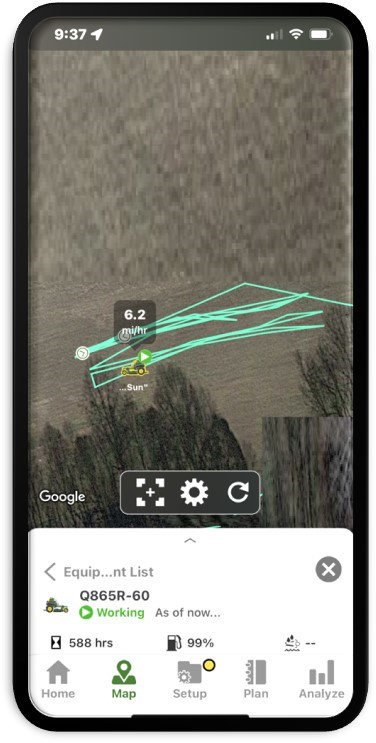

Operations Center map displaying past locations of a mower Mobile view of Operations Center map showing GPS speed

Mobile view of Operations Center map showing GPS speed The JDLink M Modem - 4G regularly transmits the location and operational status of each mower in the fleet so you can monitor mowing progress on the Operations Center.

- Location history-Display of map with current and past locations of each mower.

- GPS Speed-Maps each mower’s current and past speeds, based on GPS location data, so you can target operator training. GPS speed is only viewable on Apple iOS and Android mobile apps.

- Geofencing-Alerts when a mower enters or exits a prescribed area, for example if the mower has been stolen or an operator entered an area that should not be mowed.

- Curfews-Alerts if the mower is operating outside prescribed times, for example residential areas with early-morning noise restrictions.

Engine hours

The modem regularly transmits the mower’s engine hours to inform maintenance planning and balance use.

- Sync-The mower reports actual engine hours to the Operations Center.

- Key-Engine hours are estimated by monitoring the key switch. Engine hours can be corrected in Operations Center.

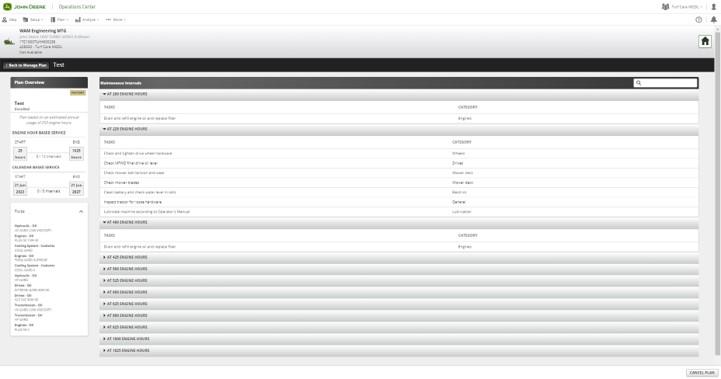

Maintenance planner

Operations Center Maintenance Planner

Operations Center Maintenance PlannerFactory or custom maintenance plans can be established in Operations Center. Maintenance alerts are sent when engine hours reach maintenance intervals.

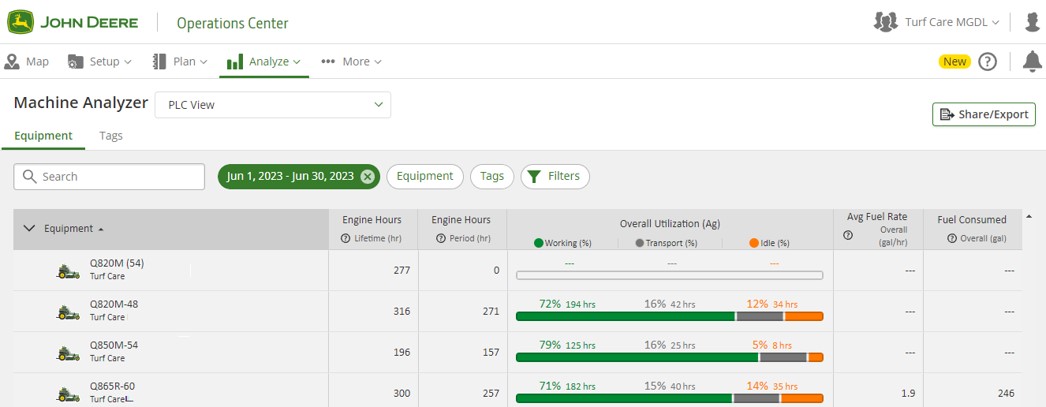

Machine Analyzer Tool

Operations Center Machine Analyzer Tool

Operations Center Machine Analyzer ToolOn select products, the modem reports the time the mower spent transporting, idling, and working. The Operations Center’s Machine Analyzer tool reports usage data which allows you to analyze operator behavior, identify causes of low productivity, and initiate corrective actions.

Fuel level

On select products, the modem reports the fuel level. On these products, an analysis of fuel consumption is available in the Operations Center Machine Analyzer Tool. Measuring fuel consumption enables you to address causes of excessive fuel use.

Diagnostic trouble codes (DTCs)

On select products, the modem transmits the trouble codes generated by the mower’s control units to the Operations Center. Addressing DTCs can reduce downtime and repair costs. For example, a low-engine oil pressure DTC can indicate an engine is low on oil. Addressing the issue can prevent costly downtime and repairs.

Service Advisor Remote

On select products, John Deere dealers can perform remote diagnostics, software programming, and adjustments without the cost of a service call.

Compatibility

A JDLink M Modem - 4G is standard equipment on model year 2024 and newer (SN 110,001-) TerrainCut Front Mowers and model year 2024 and newer (SN 690,001-) TerrainCut Wide-Area Mowers.

A JDLink M Modem - 4G can be field installed on the commercial mowing products listed below. Field installation attachments simplify modem installation, and include brackets, mounting hardware, harness, and instructions. Field installation requires a JDLink M Modem - 4G to be ordered separately.

Model | Compatible model years | Installation attachment |

Z700 ZTrak Mowers | 2024 and newer (SN 080,001-) | BUC11759* |

Gasoline-powered Z900 ZTrak Mowers | 2024 and newer (SN 130,001-) | BUC11759* |

Z994R ZTrak Mowers | 2024 and newer (SN 070,001-) | BUC11759* |

Z997R ZTrak Mowers | 2021 and newer (SN 800,001-) | To be determined |

QuikTrak Mowers | 2024 and newer (SN 010,001-) | BUC11744 |

R Series commercial walk-behind mowers | To be determined | To be determined |

TerrainCut Front Mowers | 2022-2023 (SN 080,001-110,000) | BUC11797 |

1600 TerrainCut Wide-Area Mowers | 2023 (SN 680,001-690,000) | BUC11797 |

*Expected Summer of 2024

Michelin® X® Tweel® Turf airless radial tyre technology option for a smoother ride and more uptime

Michelin X Tweel Turf on Z994R

Michelin X Tweel Turf on Z994R Flat-free rear tyre on ZTrak™ Mower

Flat-free rear tyre on ZTrak™ Mower John Deere leads the commercial zero-turn mower industry with use of the Michelin X Tweel Turf technology.

Michelin is a world leader in tyre manufacturing and technology. This airless radial tyre solution is an industry first for John Deere, which provides a smoother ride for the operator and additional advantages to John Deere owners.

Advantages of the Michelin X Tweel Turf include:

- Mowing performance is improved.

- Rutting is reduced because the Michelin X Tweel Turf has more support across the surface for improved flotation and better ground contact.

- Unique energy transfer within the poly-resin spokes reduces the bounce associated with pneumatic tyres, to give a smoother ride.

- Excellent curb climbing is possible due to the Michelin X Tweel Turf construction and flexibility.

- More consistent cut quality is achieved because inconsistent tyre pressure is eliminated.

- Uptime is improved.

- The exclusive technology eliminates downtime and associated cost due to flat or damaged tyres. Punctures and sidewall damage no longer result in downtime.

- Cost of operation is reduced.

- Cost of repairs and maintenance is reduced. One single unit replaces the current tyre, wheel, and valve assembly. There is no need for complex tyre-mounting equipment.

- No need to spend time checking and optimising tyre pressure.

- The need to purchase and stock plug kits and spare tyres is eliminated, particularly for professional landscape contractors and government agencies who normally stock them.

- The tyre tread will last up to three times longer than current pneumatic tyres because automotive-grade rubber is used for the tread.

Michelin X Tweel Turf

Michelin X Tweel Turf Michelin X Tweel Turf on Z994R

Michelin X Tweel Turf on Z994RHeavy-duty construction provides the ultimate in performance and reliable operation:

- High-strength poly-resin spokes carry the load.

- Four-hole, heavy-duty steel hub easily bolts onto any Z994R ZTrak Mower.

- Deep, open-tread design provides excellent cleaning and traction.

- Zero degree, high-tensile proprietary carcass provides great lateral stiffness while resisting damage from impact and penetration.

Tyres deliver exceptional traction, maneuverability, and reliability

Run flat front caster wheel

Run flat front caster wheel Pneumatic rear drive wheel

Pneumatic rear drive wheelThe ZTrak Z994R Mower is equipped with 13x6.5-6 run flat front caster tyres that provide:

- Excellent reliability and uptime

- Low center of gravity to increase hillside mowing capability

- Caster wheels and caster wheel towers with sealed bearings for long life and easy steering

- Offset front caster wheels to help improve the inside corner-trim performance and reduce between-blade striping

A choice of rear wheel options is available for factory installation:

- 24x12-12 4 PR pneumatic drive tyres in base equipment for excellent traction, flotation, and curb climbing

- 24x12-12 Michelin X Tweel Turf airless radial tyre technology option for a smoother ride and more uptime

Michelin, X, and Tweel are trademarks of Compagnie Générale des Etablissements Michelin SCA.

Specifications

Key Specs

- Engine Manufacturer/model

- 3TNV80F

- Engine power

- Gross at 3,200 rpm, PS: 24.7 hp

18.4 kW

- Fuel tank capacity

- 11.5 U.S. gal.

43.5 L

- Mower deck size

- Side discharge, 54 in.

137 cm

Side discharge, rear discharge, Mulch On Demand™: 60 in.

152 cm

Side discharge, rear discharge: 72 in.

183 cm

- Blade tip speed

- Side discharge: approximately 16,000 fpm

Rear discharge: approximately 15,000 fpm

- Transmission

- Dual hydrostatic wheel drive TuffTorq™ heavy-duty ground drive with cross porting for improved cooling

- Speed range

- 0-11.4 mph

0-18.3 km/h

- Drive wheels

- 24x12.00-12 4-ply turf, optional 24x12-12 Michelin® Tweel® turf tires

- Caster wheels

- 13x5.0-6 flat free

- Warranty

- 36 months or 1500 hours, whichever comes first, no hour limitation for the first 24 months.

Engine

- Manufacturer/Model

- 3TNV80F

- Power

- Gross at 3,200 rpm, PS: 24.7 hp

18.4 kW

- Displacement

- 77.3 cu in.

1.27 L

- Cylinders

- Three

- Crankcase capacity

- 3.6 U.S. qt

3.4 L

- Oil filter

- Full flow, replaceable, spin-on type

- Lubrication

- Full pressure

- Cooling

- Liquid

- Air cleaner

- Pre-cleaner

Yes

Heavy-duty canister, dry type with safety element and air-restriction indicator

- Injection

Fuel System

- Fuel type

- Diesel or Biodiesel (up to B20)

- Fuel consumption

- Fuel tank capacity

- 11.5 U.S. gal.

43.5 L

- Fuel tank switch/shut-off valve

- Yes

Electrical System

- Charge system

- 75 amp

- Battery voltage

- 12 V

- Cold cranking amp

- At 18 degrees C, 600 amp

- Hour meter

- Digital multi-function display

- Operator presence starting system

- Standard

Drivetrain

- Transmission

- Dual hydrostatic wheel drive TuffTorq heavy-duty ground drive with cross porting for improved cooling

- Hydraulic pumps

- Wheel motors

- Travel speed

- Speed range

0-11.4 mph

0-18.3 km/h

Forward

0-11.4 mph

0-18.3 km/h

Reverse

0-4.5 mph

0-7.2 km/h

- Speed and direction control

- Zero turn

- Hydraulic capacity

- 5.9 U.S. gal.

5.6 L

- Hydraulic oil cooler

- Fins and fan

- Filter

- Internal, replaceable

Buyer's Note

Tires

- Drive wheels

- 24x12.00-12 4-ply turf, optional 24x12N12 Michelin Tweel turf tires

- Rear tires

- 24x12.00-12 4-ply turf, optional 24x12N12 Michelin Tweel turf tires

- Load rating

- 4PR

Brakes

- Dynamic braking

- Twin motion control levers

- Park brake

- Internal wet disk integrated in the transmission

- Park brake actuation

- Foot brake engagement also brings steering levers to the neutral position

Pto

- Type

- Electric clutch

- Drive

- V-belt

Mower Decks

- Size

- Side discharge, 54 in.

137 cm

Side discharge, rear discharge, Mulch On Demand: 60 in.

152 cm

Side discharge, rear discharge: 72 in.

183 cm

- Deck construction

- 7-Iron™ PRO side discharge: One piece stamped steel

Fastback™ PRO rear discharge: 7-gauge fabricated steel

- Deck thickness

- 7 gauge

0.180 in.

4.6 mm

- Discharge

- Side-discharge, rear-discharge, Mulch On Demand

- Height-of-cut range

- Increments

0.25 in.

0.64 cm

1-5.5 in.

2.54-14 cm

- Cutting width

- 54, 60, 72 in.

137, 152, 183 cm

Blades

- Length

- Varies by deck size

- Thickness

- 0.25 in.

0.64 cm

Varies by deck size and configuration

- Blade tip speed

- Side discharge: approximately 16,000 fpm

Rear discharge: approximately 15,000 fpm

- Number

- Three

Wheels

- Caster wheel type

- Flat free

- Caster wheels

- 13x5.0-6

- Front anti-scalp rollers

- LH, RH, Center

- Rear anti-scalp rollers

- Standard

Dimensions

- Length

- 88.6 in.

225 cm

- Width

- With 54-in. (137-cm) side-discharge mower deck: 68 in.

172.7 cm

With 60-in. (152-cm) side-discharge or Mulch On Demand side-discharge mower deck: 74 in.

188 cm

With 72-in. (183-cm) side-discharge mower deck: 86 in.

218.4 cm

With 60-in. (152-cm) rear discharge mower deck: 63.5 in.

161.3 cm

With 72-in. (183-cm) rear discharge mower deck: 75.8 in.

192.5 cm

- Height

- With ROPS up 73 in.

185 cm

With ROPS down 47 in.

119 cm

- Weight

- 54-in. (137-cm) side discharge 1,660 lb

753 kg

60-in. (152-cm) side discharge 1,700 lb

771 kg

60-in. (152-cm) Mulch On Demand 1,720 lb

780 kg

72-in. (183-cm) side discharge 1,760 lb

798 kg

Operation

- Rollover protective structure (ROPS)

- Yes

- Slope operating limit

- 20 degrees (10 degrees with material collection system)