- 82 kW (110 hp) rated power and 89 kW (121 hp) max power (ECE-R120) + 10 kW (14 hp) IPM

- 4.5 L engine with 4 cylinders

- 6.5 t and 2.58 m wheelbase

- XXL ComfortView™ cab ( 3.33m³) with 2 panorama doors or B-Post on left hand side and Generation 4 CommandCenter™ Display with 71 d(B)A

- Transmission Choice: AutoQuad, CommandQuad, AutoPowr

Features

Connectivity inside

Automatic guidance – Make the most of your day

StarFire™ 6000 Receiver

StarFire™ 6000 ReceiverAccessing John Deere’s automatic guidance solutions starts with the StarFire 6000 Receiver. Capabilities include better signal stability for maximum uptime and SF3 accuracy. This means the receiver always keeps you on track whatever the conditions are. With SF3, you get repeatable results – no guidance line or boundary drift – throughout one season. The StarFire 6000 Receiver works seamlessly with all John Deere guidance systems and all accuracy levels (SF1, SF3, Mobile RTK and Radio RTK).

iTEC™ Pro

Intelligent Total Equipment Control integrates AutoTrac™ automatic steering and implement management systems to control tractor speed, front and rear mounted implements, and differential lock engagement, among other parameters. This allows for hands-free turns while reducing soil compaction, resulting in picture-perfect headlands and consistent crop growth.

JDLink™ system

See where your machines are and what they are doing with JDLink

See where your machines are and what they are doing with JDLinkJDLink shows where machines are, what they are doing, and how they are performing. You or your dealer can remotely assist operators with machine setup and operation leveraging Remote Display Access (RDA). JDLink Connect additionally includes Wireless Data Transfer (WDT) for seamless data exchange between the machine and the office.

Job management made easy

Job management made easy with MyJobConnect

Job management made easy with MyJobConnectEliminate paperwork and endless phone calls during job planning, execution, and reporting. With the MyJobConnect™ application, you can assign clearly defined tasks to your operators on the go, utilising the MyJobsManager app. Your operators can view work orders in real time and execute accordingly utilising the MyJobs™ app on their mobile device. Once the job is done, you have instantly accurate and complete data at hand for quicker job reporting and professional invoicing.

Operations Center

Go to the Operations Center to allocate exact field locations for the next jobs, track the work progress of your machines, easily assign work orders to operators, view as-applied maps automatically sent from the field, and create, analyse, and share application reports with trusted partners and customers.

Connectivity inside packages

With the 6R Tractor, you have a machine equipped with smart technologies that help increase profitability, comfort, and uptime while reducing cost of operation*:

- 4600 CommandCenter Display with CommandCenter AutoTrac or CommandCenter Premium activations

- 5-year JDLink Connect subscription

- Access to the Operations Center on MyJohnDeere.com

- Tractor-Implement Automation

All of the above plus a FarmSight™ dealer service package to train and support you with the use of these technologies is what John Deere has to offer for those that decide to go for connectivity inside.

*NOTE: Elements of the connectivity packages are a limited promotional offer and include time-based subscriptions.

Outstanding cab

View of cab

View of cabA commanding view

Ergonomic excellence, all-around visibility, and comfort are the hallmarks of the spacious ComfortView cab. All controls and machine/operator interfaces have been optimized for logical, intuitive use. All 6R Series Tractors are equipped with CommandARM™ controls and a Generation 4 CommandCenter™ Display. The GreenStar™ 3 2630 Display can be retrofitted on either of the right-hand-side cornerposts. The sloping engine hood and excellent all-around visibility give operators an unrivalled overview of their surroundings. The optional panoramic roof expands the operator’s field of vision, providing up to 30 percent more practical visibility when working with a front loader.

CommandARM controls and Generation 4 CommandCenter Display

ComfortView™ cab with CommandARM

ComfortView™ cab with CommandARMThe CommandARM, with its optional electronic reconfigurable joystick, provides a thoroughly intuitive operating interface. All the controls you need for daily work are available at your fingertips: selective control valves (SCVs), AutoTrac™ automatic steering, iTEC™ machine control, air conditioning, lights, radio, four-wheel drive (4WD), and hitch depth control. Mounted on the CommandARM, the Generation 4 CommandCenter display has easy-to-use, tablet-like swipe functionality and monitors everything you need for productive and efficient work.

CommandPRO™ joystick and Generation 4 CommandCenter Display

ComfortView cab with CommandPRO joystick

ComfortView cab with CommandPRO joystickThe CommandPRO joystick provides a thoroughly intuitive operating interface. All the controls you need for daily work are available at your fingertips: SCVs, AutoTrac automatic steering, iTEC machine control, air conditioning, lights, radio, 4WD, and hitch depth control. Mounted on the CommandARM, the Generation 4 CommandCenter display has easy-to-use, tablet-like swipe functionality and monitors everything you need for productive and efficient work.

Generation 4 CommandCenter Display with Extended Monitor

All 6R Tractors can be ordered with a secondary monitor mounted high on the C-post in operation with the 4600 CommandCenter Display.

The Gen 4 Extended Monitor delivers the ability to utilize an additional 25.4-cm (10–in.) monitor with the 4600 CommandCenter™ for viewing and adjusting multiple operational activities, such as a combination of planter run screens, guidance/coverage/as-applied map views, or Rate Controller settings.

Bluetooth is a trademark of Bluetooth SIG, Inc.

Comfort and agility

Smooth operator

6R Tractor

6R TractorThe Triple-Link Suspension (TLS™) Plus system guarantees optimum traction and field performance, applying up to 10 percent more power to the ground. It also ensures higher operator comfort, reduces operator fatigue, and increases productivity, while the variable ratio steering improves in-field manoeuvrability. 6R 230 and 6R 250 Tractors further benefit from extra comfort and stability that comes with the longer 2900-mm (114.2-in.) wheelbase.

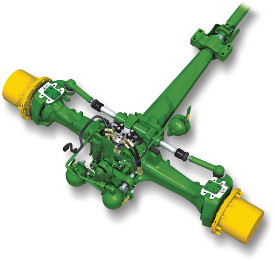

Triple-Link Suspension (TLS)

Triple-Link Suspension (TLS)Adaptive front axle

Adaptive front axle

Adaptive front axleThe self-levelling TLS Plus suspension system automatically adjusts sensitivity and suspension rate and synchronises with hitch sensing to compensate for power hop under heavy pull conditions.

Variable ratio steering

Variable ratio steering off

Variable ratio steering off Variable ratio steering on

Variable ratio steering onVariable ratio steering improves operator comfort, requiring less hand movement and less steering effort when turning on the headland or in confined spaces. The resulting faster turning of the steering wheel increases hydraulic flow, leading to a quicker response from the tyres. The system can be activated or deactivated in the CommandCenter™ display and is available for all 6R Tractors.

Performance

Engine

EngineThe high power output of the John Deere 4-cylinder, 4.5L (276 cu in.) engine and the 6-cylinder, 6.8L (418 cu in.) engine is made possible by our refined, four-valve, high-pressure common rail (HPCR) technology with an injection pressure of up to 2500 bar (36,259.4 psi). The PVS engine in the 6R 175, 6R 195, and 6R 215 models is equipped with a variable geometry turbocharger (VGT) that boosts performance and efficiency consistently across the torque curve. The PSS engines (6R 230 and 6R 250) use a two-stage turbocharging system in which the VGT multiplies the pressure created by a fixed vane turbocharger.

Superb hydraulics

Hydraulic system

Hydraulic systemThe closed-centre, pressure-and-flow-compensated hydraulic system in the 6R Series has been engineered for maximum durability and reliability by optimizing the number of hydraulic components and connections, which also makes it extremely efficient. The system in the 6R 230 and 6R 250 models delivers a powerful 160 L/min (42.3 gpm) at 1,500 rpm with enhanced operating characteristics. Selective control valve (SCV) stack components have been clustered in a supremely user-friendly way, with up to six rear SCVs and power beyond couplers. Wide hitch rails allow generous clearance for power take-off (PTO) tasks, and the layout gives the operator an unobstructed view of the rear hitch and connecting points when manoeuvring for implement coupling.

Widest transmission portfolio

AutoQuad™ transmission

6R Tractor

6R TractorThe AutoQuad transmission has all the benefits of the PowrQuad™ PLUS transmission with the added convenience of automatic gear shifting. It is available in 20F/20R and 24F/24R versions with and without creeper. With the EcoShift option, a transport speed of 40 km/h (25 mph) is maintained at only 1533 rpm, reducing fuel consumption and emissions.

Enhanced AutoPowr™ transmission – Infinite speed adjustment in all situations

AutoPowr transmission

AutoPowr transmissionAutoPowr is a hydro-mechanical transmission delivering stepless and continuous power at maximum speeds of 40 km/h or 50 km/h (25 mph or 31 mph). The AutoPowr transmission maintains the selected speed by automatically responding to changing load conditions. Once running at maximum road speed, engine rpm automatically drops to the minimum level required to maintain that speed, thus reducing noise and saving fuel. A speed of 50 km/h (31 mph) is maintained at 1630 rpm, and a speed of 40 km/h (25 mph) is maintained at 1300 rpm with the CommandPRO™ joystick.

DirectDrive transmission – The benchmark for seamless efficiency

DirectDrive transmission

DirectDrive transmissionSpecifically developed for 6R Tractors, DirectDrive is an eight-speed, three-range transmission designed and engineered by John Deere for heavy agricultural work. Super-efficient dual-clutch technology always has the next gear lined up, so there is no lost momentum during changes, fuel consumption is reduced, and ease of operation is assured. During transport, DirectDrive reduces the engine speed to 1550 rpm at 40 km/h (25 mph) and 1600 rpm at 50 km/h (31 mph), thus reducing fuel consumption. In addition, the AutoClutch function enables you to stop the tractor without pressing the clutch.

Specifications

Key Specifications

- Rated Engine Power (97/68EC)

- 82 kW (110 hp)

- Transmission type

- PowrQuad™ PLUS, AutoQuad™ PLUS or

IVT™ with optional creeper

- PTO

- 540/540E/1000

- Rear Hitch lift capacity

- 3,350 kg