- Available in the following models:

- Standard (dry hay)

- MegaWide™ HC² feed system with Precutter

- Silage

- BaleTrak™ Pro-monitor controller

- Exclusive DiamondTough™ triple weave belts

Features

0 Series Round Balers - Model specification levels

Round baler models

| Model | Bale size | Available pickups |

| 450E | 1.2 x 1.5 m (4 x 5 ft) | Regular |

| 450M | 1.2 x 1.5 m (4 x 5 ft) | Regular, MegaWide™ Plus |

| 460M | 1.2 x 1.8 m (4 x 6 ft) | MegaWide Plus, MegaWide HC2 |

| 460R | 1.2 x 1.8 m (4 x 6 ft) | MegaWide Plus, MegaWide HC2 |

| 550M | 1.5 x 1.5 m (5 x 5 ft) | Regular, MegaWide Plus |

| 560M | 1.5 x 1.8 m (5 x 6 ft) | Regular, MegaWide Plus |

| 560R | 1.5 x 1.8 m (5 x 6 ft) | Regular, MegaWide Plus, MegaWide HC2 |

Round baler model specification

| Baler option | Applicable models |

E = Economy

| 450E |

M = Standard

| 450M, 460M, 550M*, and 560M |

R = Premium

| 460R and 560R |

*NOTE: The 550M Round Baler will only be available in dry hay and silage configurations.

MegaWide™ High Capacity and Cutting (HC2) feeding system

0 Series Round Baler

0 Series Round BalerThe 0 Series Round Baler family welcomes the first, John Deere, North-American built precutter. This feed system in front of these machines is the MegaWide HC2. The MegaWide Plus name is known as the industry-leading feed system since its introduction with the 7 Series Balers. John Deere continues that legacy with the 0 Series. Proven designs of the MegaWide were maintained and improvements were made to key components to gain significant capacity.

Features of the MegaWide HC2

The MegaWide™ HC2 will only be available in a precutter configuration (available on the 450M, 460M, 460R, 560M, and 560R models):

- 1.22-m (4-ft) wide machines will have 14 knives

- 1.52-m (5-ft) wide machines will have 20 knives

The MegaWide HC2 has the same 2.2-m (7.22-ft) MegaWide Plus pickup from the 9 Series. Dry hay and silage 0 Series configurations will also have the MegaWide Plus pickup.

Baler driveline

Baler driveline Greasing in one location

Greasing in one locationBefore the introduction of the MegaWide HC2 , the cam-clutch protection for the driveline was only available on the 9 Series Premium Balers. It is in the base for the MegaWide HC2 precutter configurations. This driveline pushes the limitations of the baler and the MegaWide HC2 system by offering the best machine protection John Deere can provide.

Another feature brought over from the 9 Series Premium Balers and being offered on the 0 Series is the grease banks. All daily greasing can be done from the ground in one central location.

MegaWide HC2 roller baffle and MegaWide Plus roller baffles

MegaWide HC2 roller baffle and MegaWide Plus roller bafflesThe roller baffle on the MegaWide HC2 doubled in size from the MegaWide Plus from 10.2-cm (4-in.) to 20.3-cm (8-in.) diameter to allow for increased speeds and performance in larger windrows.

560R Baler width

560R Baler width 450M Baler width

450M Baler widthThe 450M, 460M, 460R, 560M, and 560R Balers that can be configured with the MegaWide HC2 feed system will have the same flare-to-flare pickup width of 2.2 m (7.21 ft). This 2.2-m (7.21-ft), flare-to-flare, width on 1.22-m (4-ft) balers is only a feature of the MegaWide HC2 feed system.

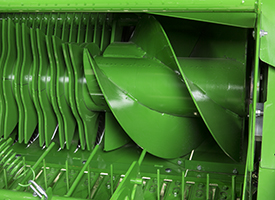

Primary rotor relationship to knives – front position

Primary rotor relationship to knives – front position Primary rotor from bale chamber

Primary rotor from bale chamberThe primary rotor is only available on the MegaWide HC2 and is located directly behind the MegaWide pickups.

- This rotor grabs the crop and drags it over the knives to size the crop to a theoretical length size of 66 mm (2.5 in.)

- For the 1.22-m (4-ft) machines, there are 14 slots to receive the knives that are located on the floor of the feed system

- The 1.52-m (5-ft) machine has 20 knives and 20 slots

Fast-pitch augers on the primary rotor

Fast-pitch augers on the primary rotorIndustry-exclusive, fast-pitch augers have been placed on the primary rotor to move dry hay and silage past the transition points to avoid plugging.

MegaWide HC2 secondary rotor from bale chamber

MegaWide HC2 secondary rotor from bale chamberThe secondary rotor is another component on the feed system that was re-designed from the MegaWide Plus feed system to handle the increased demands of the high-capacity system.

- The secondary rotor in the MegaWide HC2 is similar in location and design as the MegaWide Plus spiral rotor.

- The hex shaft on secondary rotor rotor on the MegaWide HC2 was increased from 3.2 cm (1.25 in.) from the MegaWide Plus to 3.8 cm (1.5 in.)

- The diameter of the tube was increased for additional strength and to prevent silage wrapping

- The number of tines was increased from two to three for additional capacity and flow of crop into the starter roll and chamber.

Drop floor

Drop floor Drop floor

Drop floorDrop floor – if the baler exceeds capacity and plugs, the MegaWide HC2 can lower the knife floor from the cab of the tractor to easily feed the plug into the chamber.

- Drop floor is an insurance policy to allow the operator to push the machine knowing that a plug can clear in 30 seconds, not 30 minutes.

- In factory-observed testing with the 2016 test fleet, 99 percent of the plugs were cleared from the cab.

- Floor is self-cleaning – when lowered to feed a plug, it allows chaff that has been built up around the knives to fall through into the windrow.

- This release of crop allows the feed system to stay cleaner

- Allows for easier engagement of the knives and servicing of the knives

- The floor is also responsible for engaging the knives

- Based on lack of success for re-engaging knives in competitive machines, John Deere made sure the MegaWide™ HC2 was built to meet the demands a Deere producer expects.

- Knife-engagement forces on the MegaWide™ HC2 are 10 times that of the New Holland™ Roll-Belt™ 460 CropCutter® Baler. It gives the producer the confidence that if the knives are engaged, they are all up and cutting.

- Once the knives are up, each knife has individual spring protection, limiting bent or broken knives.

- Hit a rock and the knife moves out of the way and automatically re-engages.

Third drive roll

Third drive rollA third drive roll is another feature that will only be offered with the MegaWide HC2 feed system.

- Precutting crop releases additional moisture into the feed system of the baler so the MegaWide HC2 feed system added a third drive roll on the number 11 roller to ensure trouble-free bale formation even in the most difficult, high-moisture silage conditions.

- This feature is available only on the MegaWide HC2 feed system

External belt guides

External belt guidesAll MegaWide HC2 feed systems will have silage components to limit maintenance and prevent crop build up on belts.

- Driven auger

- Starter roll scraper knife

- Auxiliary take up roller

- For precutter machines only - external belt guides

- External belt guides were designed to dramatically reduce amount of chaff in the gate

- Available through parts – retrofittable through 7 Series balers

Increased torque – the MegaWide HC2 feed system required an additional drive configuration to power the primary rotor and to meet the capacity goals.

- The MegaWide HC2 feed system has a T gearbox where the MegaWide Plus has a 90 degree box.

- The MegaWide Plus system had a cut-out clutch that protected the spiral rotor and pickup.

- The MegaWide HC2 eliminated that clutch because the secondary rotor is more robust than the MegaWide Plus spiral rotor.

- This allowed the primary and secondary rotor to be driven directly from the driveline.

- Both components are still clutch protected from the main driveline cam clutch, but there is approximately 10 times more torque being put through the primary and secondary rotor than what is found on the MegaWide Plus spiral rotor.

- This exponential change in torque is the driving force of the capacity gains in the MegaWide HC2 feed system.

- MegaWide HC2 pickup is still clutched for extended pickup life. That clutch is now located on the left-hand side of the baler. MegaWide Plus pickup clutches are still located on the right-hand side of the baler.

MegaWide HC2 feed systems will not have the adjustable crank handle for the pickup.

- MegaWide Plus machines will continue to have this an option.

Descriptive model numbering system

All 0 Series Balers use alpha-numeric identifiers for the model names:

The MegaWide HC2 can be ordered on mid specification (M) and premium specification (R) balers.

R specification balers will have the premium pickup with improved internal components that are covered under the 2-year/12,000-bale premium warranty

M specification balers and pickups will not contain premium baler components – exception for this is the MegaWide HC2 feed system will have the premium cam clutch for the driveline and grease banks.

For more information about the model specifications, see the chart below:

| Baler option | Applicable models |

E = Economy

| 450E |

M = Standard

| 450M, 460M, 550M*, and 560M |

R = Premium

| 460R and 560R |

*NOTE: The 550M is only available in dry hay and silage configurations.

New Holland, Roll-Belt, and CropCutter are trademarks of CNH Global N.V. and its subsidiaries.

MegaWide™ Plus pickup with MegaTough™ pickup teeth offers super capacity

460M MegaWide Plus pickup

460M MegaWide Plus pickupA MegaWide Plus pickup is available on 450M, 550M, and 560M Round Balers. It is base equipment on the 450M Silage, 550M Silage, 460M, 460M Silage, and 560M Silage Balers. The MegaWide Plus pickup is also incorporated into the new MegaWide High Capacity and Cutting (HC2) high-capacity precutter feed system.

0 Series Balers have implemented specification levels for all models in the baler lineup, similar to what was done when the 459E was introduced. Pickup options will remain the same for the model's equivalent specification. The precutter pickups will have the same MegaWide Plus pickups that will be offered in mid specification (M) or the premium specification (R) balers.

MegaWide Plus pickups make baling easier, especially in wide or windblown windrows, and increases productivity; more hay volume means more bales per hour.

- Flare-to-flare width of 1.8 m (5.9 ft) on balers with a 1.2 m (4-ft) wide bale chamber

- The MegaWide HC2 Precutter feed system on the 460M offers a 2.2 m (7.2-ft) wide flare-to-flare pickup width; 20 percent wider than our previous offerings on the 1.2-m (4-ft) wide balers.

- MegaWide Plus pickup makes it easier to produce better-shaped bales and improves crop pickup in wide, windblown, or scattered windrows

- Mega teeth, located at the ends of the pickup, pull crop around the flares when baling wide or windblown windrows

- MegaTough pickup teeth provide greater strength and durability

- Exclusive square design handles high-impact loads without yielding

- Sturdy toothbar design

- Self-adjusting roller baffle

- Spiral rotor-feed system improves feeding in all crop conditions

- Chain driven for positive feeding

- Cut-out clutch protected

- Semi-pneumatic gauge wheels

MegaTough pickup teeth

MegaTough pickup teethMega and MegaTough pickup teeth are base equipment:

- Mega teeth, at the ends of the pickup, are heavy-duty for long life and improved crop retrieval

- MegaTough pickup teeth are designed to withstand the harshest baling conditions and provide long service life

Toothbars on 1.5-m (5-ft) baler

Toothbars on 1.5-m (5-ft) balerThe 1.2-m (4-ft) balers use a full-length, reinforced toothbar design.

The 1.5-m (5-ft) balers use a heavy, C-channel construction. The pickup toothbars are divided into two half-sections that mount to a center spider for increased strength and even crop feeding.

Roller baffle

Roller baffleAvailable only on the MegaWide Plus pickup, the patented roller baffle is self-adjusting and produces smoother crop flow across the pickup. The roller also improves crop pickup in small windrows and prevents roll ahead of crop.

When combined with the MegaWide Plus pickup, this feeding system allows increased ground speed with less chance of plugging for increased productivity in all field conditions.

- Self-adjusting

- Smooths crop for even flow across pickup

- Allows for faster ground speed with less chance of plugging

- Increases operator productivity

Spiral rotor

Spiral rotor Auger and rotor feed system

Auger and rotor feed systemThe MegaWide Plus pickup uses a rotor-feeding assembly, which mounts behind the pickup for smooth and even crop flow into the bale chamber.

- Augers and rotor teeth are driven on the same shaft, eliminating the need for additional drives.

- The rotor is fixed to the baler frame, allowing positive and even feeding into the bale chamber.

- Large-diameter converging augers have high crop-flow capacity, and auger scrolls help to force crop into the chamber.

- Spiral design enhances feeding in uneven windrows and reduces loading on the rotor.

Rotor stripper

Rotor stripperRotor strippers allow crop to be lifted from the rotor teeth into the chamber without cutting or wrapping the crop.

Cut-out clutch protection and feeder-drive chain

Cut-out clutch protection and feeder-drive chainThe MegaWide Plus pickups and spiral rotor are chain-driven for positive bale starts with cutout clutch protection. The pickup is being driven off the drive roll and bypasses the starter roll. This will allow for reduced wear and breakage of the starter roll chain.

Semi-pneumatic gauge wheel

Semi-pneumatic gauge wheelSemi-pneumatic gauge wheels provide smooth ground gauging over uneven terrain and protection to the pickup.

- Stiffer rubber sidewalls

- No air pressure to maintain, which mean no flat tires

- Adjustable to meet pickup tooth-to-stubble height requirements

The pickup float springs are positioned for excellent flotation.

- Adjustable to meet varying field conditions

- Float springs only support the pickup reel

- Rotor assembly is fixed to the baler frame, eliminating additional weight on the pickup system

Adjustable crank handle

Adjustable crank handleThe adjusting crank positions the pickup to the desired operating height to match crop or field conditions.

An optional hydraulic pickup lift cylinder is available as an attachment.

- Makes raising for transport or clearing obstructions easy

- Crank handle serves as a down stop

- Adapts to regular, MegaTooth and MegaWide Plus pickups

- Hydraulic pickup lift comes standard on premium machines

Silage configuration

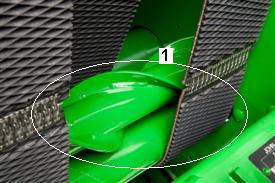

Staggered roller-auger kit

Staggered roller-auger kitA silage-configuration baler allows the producer to put up silage hay. A silage configuration machine does not offer a precutter. There are three major components to a silage configuration baler: a staggered roller-auger kit (1), a starter roll-scraper knife, and a screen (2). The powered auger sits above the staggered roll on the baler to help keep wet hay from traveling up the belts and reduce buildup on the roll. The screen is bolted on the front of the baler as a safety feature. The knife/scraper is mounted in front of the starter roll to help prevent wrapping of wet crop on the starter roll.

The silage kit is offered as a bundle for field installation if the baler is not ordered as a silage-configuration machine from the factory. Attachment BE32442 is for 1.22-m (4-ft) wide machines and BE32443 is for1.52-m (5-ft) wide machines.

Also offered is a high-moisture kit. This kit does not include the same components that are on the silage-configuration balers. It offers the starter roll-scraper knife but does not include the staggered roll-auger kit. Attachment BE23828 is for 1.22-m (4-ft) machines and BE23829 is for 1.52-m (5-ft) machines.

Starter roll knife and screen

Starter roll knife and screenBase equipment on: 450M Silage, 550M Silage, 460M Silage, 560M Silage, 450M Precutter, 460M/R Precutter and 560M/R Precutter.

Auxiliary take-up rolls

Auxiliary take-up rollsAuxiliary take-up rolls prevent belt crossover and flipping in wet conditions. This roll is base equipment on all silage and precutter configuration balers. It also comes with the bale ramp bundle on the 440E and 450E Balers.

Precutter configuration

The 0 Series Round Baler family welcomes the first, John Deere, North-American built precutter. This feed system in front of these machines is the MegaWide HC2. The MegaWide Plus name is known as the industry-leading feed system since its introduction with the 7 Series Balers. John Deere continues that legacy with the 0 Series. Proven designs of the MegaWide were maintained and improvements were made to key components to gain significant capacity.

The MegaWide™ HC2 will only be available in a precutter configuration (available on the 450M, 460M, 460R, 560M, and 560R models):

- 1.22-m (4-ft) wide machines will have 14 knives

- 1.52-m (5-ft) wide machines will have 20 knives

The MegaWide HC2 has the same 2.2-m (7.22-ft) MegaWide Plus pickup from the 9 Series. Dry hay and silage 0 Series configurations will also have the MegaWide Plus pickup.

Regular pickup offers large feed opening and low-profile, mid-mounted pickup

Regular pickup on 450E Baler with converging wheels

Regular pickup on 450E Baler with converging wheelsMounted in front of the baler wheels and directly below the bale chamber, the pickup hugs the ground for clean crop retrieval. Hay movement is minimized.

- V-belt driven

- 450E and 450M Baler pickups are 116.6 cm (45.9 in.) wide

- 550M and 560M Baler pickups are 156 cm (61.4 in.) wide

- Large reel shaft and reel bearing

The small-diameter, low-profile pickup allows for good ground gauging and clean crop retrieval.

- Handles large, heavy windrows of hay and high-moisture crops

- Feeds hay directly to the forming chamber to reduce crop loss

- Low-profile pickup minimizes hay lift to reduce chaffing and retain hay quality

Side flares prevent hay from blowing off the pickup ends, which reduces hay loss.

The closely-spaced pickup teeth extend to the baler side sheets to help build straight-edged bales.

Standard on regular pickups, compressor rods are contoured to control hay over the pickup radius for positive feeding. The compressor rack can be adjusted upward or downward to match the volume of material in the windrow and can be easily removed to match crop conditions.

Adjustable crank handle

Adjustable crank handleThe adjusting crank positions the pickup to the desired operating height to match crop or field conditions.

An optional hydraulic pickup lift cylinder is available as an attachment.

- Makes raising for transport or clearing obstructions easy

- Crank handle serves as a down stop

- Adapts to regular and MegaWide™ Plus pickups

- Hydraulic pickup lift comes standard on premium machines

NOTE: Crank is not an option for the MegaWide High Capacity and Cutting (HC2) feed system.

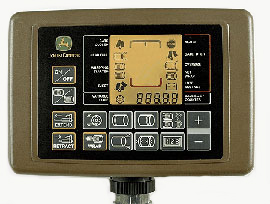

Automatic electric-tie option using BaleTrak™ Pro monitor allows for more productivity

Audible alarm

BaleTrak Pro monitor-controller

BaleTrak Pro monitor-controllerThe BaleTrak Pro monitor-controller is included with the automatic electric twine tie option and the Edge-to-Edge net wrap option on the 450E Baler. The monitor sounds an alarm for near-full, full, and oversized bales.

- Monitor beeps once to notify the operator to even-up the bale prior to reaching the desired size.

- Monitor beeps twice when the bale reaches the desired size.

- If the operator continues to feed hay into the baler, the monitor will sound continuously to warn of an oversized bale.

- Bale shape bars are not available on the 450E Round Balers. The 450E Round Balers allow for adjustment of twine settings from the cab by using the BaleTrak Pro Monitor.

- The number of wraps on the Edge-to-Edge net wrap option on the 450E can be set with the BaleTrak Pro.

The audible level of the monitor can be adjusted.

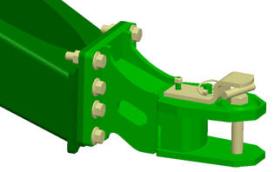

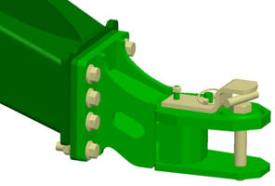

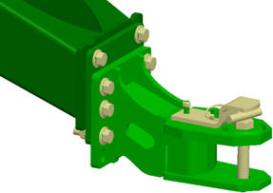

Adjustable hitch to match wide array of tractor drawbar heights

Side view of adjustable hitch

Side view of adjustable hitch Front view of adjustable hitch

Front view of adjustable hitchThe 9 Series Round Balers came standard with an adjustable hitch and this feature will continue to be in base with the 0 Series Round Balers. This feature allows the hitch height to be adjusted to optimize crop-feeding performance. Due to the wide array of tractor tire sizes and drawbar heights, hitch adjustment may be necessary to get the proper feed opening of the baler. The adjustable hitch eliminates the need for the 51-mm (2-in.) thick tractor drawbar kit (AE57344) because it has a wider opening.

Benefits of the adjustable hitch:

- Ability to match baler to numerous tire sizes

- Allows for drawbar height to fall within 330 mm to 559 mm (13 in. to 22 in.) from the top of the drawbar to the ground

- Eliminates narrow feed opening on the baler which can cause plugging

- Allows pickup head to follow terrain without missing crop

All eight bolts must be used when adjusting the hitch. There are four different positions as shown below:

Position 1 (top) (factory setting) - regular pickups

Position 1 (top) (factory setting) - regular pickups Position 2

Position 2 Position 3 (factory setting) - MegaWide Plus and MegaWide HC2

Position 3 (factory setting) - MegaWide Plus and MegaWide HC2 Position 4 (bottom)

Position 4 (bottom)Also standard on all 0 Series Round Balers, except the 450E, is the drawbar shield. This helps to eliminate hay from getting caught on the hitch of the baler. The drawbar shield is designed to allow the operator to remove or attach the flap without having to unhook the baler from the tractor.

Drawbar shield

Drawbar shield Drawbar shield installed on baler

Drawbar shield installed on balerVertical forming chamber maintains uniform bale density

Bale-starting diagram

Bale-starting diagramAs the hay enters the forming chamber from the pickup, belts immediately turn the hay to form a tight, dense core.

Incoming hay then feeds between the bale and the lower gate roll. Hay is tightly compressed into smooth, dense layers as it enters the bale.

Chaffing is greatly reduced to prevent loss and retain hay quality in the bale.

Full-sized bale in bale chamber

Full-sized bale in bale chamberThe idler arm rises with bale growth, forcing oil from the hydraulic cylinder through a pressure-relief valve to maintain uniform bale density throughout the bale-forming process.

Exclusive DiamondTough™ belts with plate-type splices

Staggered belts

Staggered beltsJohn Deere's 178-mm (7-in.) wide diamond-tread design ensures fast bale starts and grips the bale to prevent slippage and reduce chaffing. The treads are self-cleaning to reduce carryover. The belts are staggered to reduce the loss of fine material and are closely spaced to contain the hay for fast, easy starts.

The belts enclose 91 percent of the bale width to reduce loss of fine material and retain hay quality.

The staggered belt roll design enables any loose hay under or behind the belts to be returned to the pickup and into the baler. This design helps to prevent buildup at the front of the baler, which could cause hay loss and belt or splice damage.

DiamondTough triple-weave belts

DiamondTough triple-weave belts

Every baler in the 0 Series Family uses DiamondTough belts. Belts are constructed using a patented triple-weave process of nylon and polyester materials.

They have the strength to handle heavy shock loads and help maintain consistent belt length.

The DiamondTough belts are more puncture and tear resistant than other belts on the market and provide improved belt life and reliability.

Plate-type fasteners

Plate-type splices

Plate-type splices

All of the 0 Series Balers use the plate-type fasteners.

This closed-loop design uses a plate fastener with pre-assembled rivets that lock the fasteners into the belt, providing a powerful vice-type grip on the belt.

- The plates and rivets are manufactured from high-tensile stainless steel.

- Strong belt splices mean less maintenance and more productivity.

- The loop area is cold forged, making it extremely wear resistant in the coupling area, resulting in a very long cycle life.

- The spring steel pin is notched and locks into the splice connection without having to bend the pin or use external retainers.