- PowerTech™ M 2.9 L Engine

- 12F/12R transmission with left-hand PowrReverser™

- 4-wheel-drive

- 540 & 540E PTO

Features

Field-proven engine technology

Since January 2008, the European Union (EU) has adopted the guidelines set out in the Stage IIIA emission regulations for all tractors sold in the EU between 50 hp and 100 hp. To satisfy these requirements, which are comparable to the U.S. Tier 3 norm, John Deere has chosen the best technology for all its 5E Tractors.

The PowerTech™ engine generation allows the tractors to meet producers’ demands for a powerful, fuel-efficient tractor as well as Stage IIIA emission levels.

Durability and performance

Outstanding engine features:

- Economical three-cylinder engine

- Field-proven mechanical injection technology

- High-strength block design

- Fuel-saving variable eco fan (viscous fan drive)

- Free-breathing, cross-flow cylinder heads

- Wet cylinder liners

- Highly efficient charge air cooler

- Fuel cooler

Mechanical injection pump

Mechanical injection pump

Mechanical injection pumpA mechanical distributor-type injection pump with precise and responsive fuel measurement is used on the 5E Series Tractors.

This pump is equipped with a mechanism that regulates the fuel quantity based on the turbocharger pressure. This technology helps to fulfill the stringent emission regulations set out in Tier 3 and to avoid black smoke.

The pump is self-lubricating and, therefore, maintenance free.

The automotive-style electrical shutoff provides positive engine shutdown, enhancing while reducing noise and improving driver comfort.

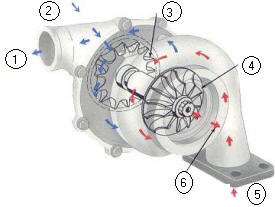

Turbocharger

Turbocharger

Turbocharger- Air to engine

- Air in

- Compressor wheel

- Turbine wheel

- Exhaust in from engine

- Exhaust out

All 5E Series Tractor engines have a fast-response turbocharger to increase engine power and torque.

The 3-Cylinder 5E Tractor engines have a high-exhaust gas velocity in their short-exhaust manifold system and achieve the best performance with a single-channel turbocharger.

The carefully matched turbocharger and engine settings allow economical performance and environmentally friendly engines.

Dual air cleaner

Dual air cleaner

Dual air cleaner- Exhaust in form engine

Dry air cleaners are equipped with a primary and secondary dual filter element.

This ensures a 99.9 percent supply of clean air to the engine, which enhances engine life.

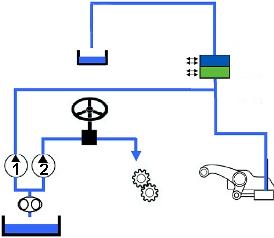

Independent open-centre hydraulic

Two independent pumps

Two independent pumps

Two independent pumps- Lift

- Steer

The open-centre hydraulic circuit on the 5E Series features independent hydraulic performance for

steering and the high-pressure rockshaft and selective control valves (SCVs).

An engine-driven tandem gear pump supplies power to this system. This pump is basically two pumps

working together as one to provide a high-flow rate of up to 71 L/min (18.8 gal./min). The front half of the pump supplies 25-L/min (6.6-gal./min) hydraulic flow to the steering circuit. The rear half of the pump delivers 46-L/min (12.2-gal./min) hydraulic flow to the SCVs and 3-point hitch. This tandem pump system ensures excellent hydraulic performance and capacity:

- Precise steering without removing the oil flow from the SCVs and rockshaft is ideal for manoeuvring and operating an implement at the same time as turning at the headland.

- Dedicated rear pump with 46-L/min (12.2-gal./min) flow ensures maximum flow to the SCVs and rockshaft for demanding implements.

- Ensures easy power steering with heavy loads on the front of the tractor.

- Supplies plenty of power for running hydraulic motors.

- Provides high-loader breakout force and fast cycle times.

Service-friendly oil check

Service-friendly oil check

Service-friendly oil checkThe filler neck for the transmission and hydraulic oil is located at the rear of the tractor for easy, unobstructed access during servicing. The filler cap has an integrated dipstick to accurately measure the oil level in the transmission.

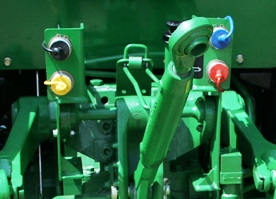

SCV options

SCV options

SCV optionsThe 5E Series offers up to two mid or rear SCVs. Either two mid SCVs in combination with one rear SCV or two rear SCVs without mid SCVs can be ordered. All SCVs have quick push couplers as standard.

All optional SCVs can be operated comfortably via the joystick.

One double-actuating SCV is standard on each 5E.

Power steering

Power steering

Power steeringPower steering ensures high-lifting performance even during simultaneous steering. The extra 25-L/min (6.6-gal./min) pump takes care of quick turning manoeuvres.

Power steering offers effortless and comfortable steering.

Spacious platform with logical ergonomics

Easy operable and comfortable workplace

Easy operable and comfortable workplace

Easy operable and comfortable workplaceThe work space on 5E Series Tractors is very spacious and easy to enter and exit from both sides. All controls are easily accessible and positioned intuitively so that even inexperienced drivers can quickly find their way around the tractor.

Controls are colour coded: power take-off (PTO) levers in yellow, driving levers in orange, and hydraulic levers in black. To fulfill the European Union (EU) requirements regarding low noise levels, the whole driver interface is isolated from vibrations and sounds from the engine and transmission.

Closed platform at the rear

Closed platform at the rear

Closed platform at the rearThe platform at the rear is closed, which not only allows for more storage room for the driver's personal belongings, it also offers protection against mud flying up from the back of the tractor.

Full-coverage bumpers

Full-coverage bumpers

Full-coverage bumpersBumpers cover the whole tyre from the top to the bottom of the platform. This keeps the platform clean from soil flying up from the wheels. Indicator and position lights are integrated in the bumpers to protect them while driving across trees, acting as a windbreak at the headland.

Full-coverage bumpers are a lone-standing John Deere feature in this tractor class.

Front-protection shields

Front-protection shields

Front-protection shieldsThe platform is closed at the front with shockproof Perspex® shields to protect against wind and dirt from the front wheels. A clear view to the front is guaranteed.

Joystick for selective control valve (SCV) operation

Joystick for SCV operation

Joystick for SCV operationFor the second SCV option, 5E Tractors have a separate joystick to operate two SCVs simultaneously.

Standard beacon and work light

The standard beacon light ensures that 5E operators can be seen when driving on roads.

The rear work light is also included as standard to enhance visibility at night.

Adjustable seat with seat belt

Adjustable seat with seat belt

Adjustable seat with seat beltSeats are adjustable and water resistant. For additional safety, a seat belt is installed as standard.

The adjustment knob is located behind the seat. Weight marks are given on the rear of the seat. Seat suspension functions according to the operator’s weight.

Adjustment knob

Adjustment knobTiltable roll-over protection structure

Tiltable roll-over protection structure

Tiltable roll-over protection structureFor working where there is limited height clearance—for example, in vineyards, nurseries, orchards, olives, or other tree cultivations—5E Tractors are equipped with foldable roll-over protection structures. This also means that low-level barns and cowsheds can also be entered with ease. A telescopic mirror is also placed within easy reach of the seat.

Toolbox

Toolbox

ToolboxThe 5E Series Tractors have a portable toolbox fitted next to the right-hand-side foot step.

Perspex is a U.S.-registered trademark of Lucite International.

Cabs increase comfort and performance

Climate-controlled cab interior

Climate-controlled cab interiorThe operator of a 5E Series will appreciate the reduction in noise and vibration through the seat, steering wheel, and lever controls with a rollover protection structure (ROPS) certified, factory-installed cab.

The cabs are assembled to the tractor chassis as a complete unit and mounted on composite isolators. This system of assembly and mounting is similar to the successful mounting methods of the

larger-horsepower tractors in the John Deere Ag tractor family.

The complete cab assembly includes the floor and steering column. Having this type of fully isolated cab greatly reduces noise levels inside the cab. It also creates a more sealed environment, so the amount of airborne particles entering the cab, such as dust and pollen, are greatly reduced.

The cab is very spacious, allowing ample space for controls and storage. The flat floor adds to the spacious, open feel.

The ceiling control panel is located on the upper-right side and the air-conditioning components are located on the upper-rear corners of the cab, where visibility is not as critical. This provides the operator with visibility to the loader at a height unmatched by any competitor.

Operator environment

Easy-to-reach side heater and air-conditioning controls

Easy-to-reach side heater and air-conditioning controlsThe 5E Series cabs provide a clean, quiet environment protected from the elements. Powerful air-conditioning and heating systems allow the operator to control the cab climate to preference, regardless of the conditions outside. The standard visor blocks the sun on bright days, while a dome light allows the operator to see controls at all times of the day.

The cab's side windows open forward for excellent ventilation and left-side door open wide for easy entry and egress.

The rear window opens to 70 degrees, providing further visibility when hooking up implements. An interior rearview mirror provides additional visibility.

The clean, uncluttered interior design with flat platform maximises operator space. A conveniently located beverage holder provides space for the operator's drink of choice.

Take further pleasure in the ride with a radio or compact-disc player available as a field-installed attachment. Cabs are radio ready, including standard speakers and radio wiring harness.

Operating controls

Excellent overall visibility in all applications with a swing-out rear window opens to a full 70 degrees for easier implement hook up and visibility. A front windshield wiper with washer ensures the operator can see the surroundings of the tractor (a rear wiper is available for field installation).

Excellent night visibility is achieved with work lights, easily adjusted to redirect light without tools.

A convenient three-pin power outlet is for a monitor, controllers, and other operating necessities. Four sets of mounting bosses and a removable rear access plug for monitor or controller harnesses also make using a monitor easy.

A rear seven-pin electrical-outlet socket for implement electrical requirements and a 90-amp alternator handles increased electrical requirements. To handle increased powertrain and hydraulic requirements in severe conditions, hydraulic oil cooler is standard.

Additional features are as follows:

- Front work lights

- Radio

Deluxe cloth seat

A deluxe cloth seat with a retractable seat belt is in base equipment:

- An ergonomically sculpted seat cushion, an adjustable scissor-link suspension, and seat armrests are combined to provide excellent operator comfort and support.

- The scissor-link suspension can be adjusted for the operator's height and weight.

- The operator weight adjustment adjusts to the operator's weight 52 kg to 125 kg (115 lb to 275 lb).

- Seat is adjustable fore and aft for the operator's height, using the lever located under the seat.

- Retractable seat belts prevent the belts from becoming tangled in the seat suspension and controls.

Largest cab in class

TechCenter cab

TechCenter cabThe TechCenter cab is the largest in the 55 to 80 engine hp tractor class. It features a unique-to-the-market comfort zone with an ample amount of space, luxury upholstery, three cup holders, and multiple storage places for mobile devices and food. The upholstered driver seat comes with armrests, mechanical weight, and horizontal adjustment.

High front view to front loader in upper position

Full view in loading operations

Full view in loading operationsThe front window of the TechCenter cab is pulled to the top of the roof. Air conditioning, heating, and radio controls are moved to the side of the roof to allow full view during loading operations.

Tiltable and telescopic PowrReverser™ lever and steering wheel

PowrReverser lever in tilt steering column

PowrReverser lever in tilt steering column The electric PowrReverser lever can be operated by hand from the steering wheel while turning at the headland.

The steering wheel and reverse lever can be tilted horizontally as well as extended or retracted vertically, which provides operator comfort. In addition, this feature makes steering more comfortable during long days.

NOTE: The tilt and telescopic function is only available on cab models. Not available with isolated open-operator station (IOOS) variants.

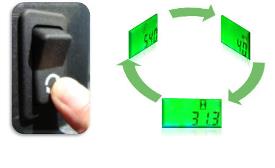

Smart board computer

Control switch

Control switchThe driving and power take-off (PTO) speeds can be controlled with the one-button, digital-display computer control, which allows the operator to save fuel and fertiliser. The smart board computer and switch are located in the front console.

Top-shaft synchronised transmission

The 5E Series Tractor lineup offers the reliable nine-forward/three-reverse (9F/3R) top-shaft synchronised transmission. The concept of the proven 5E Series transmission provides:

- A wide choice of transmission speeds

- Easy and comfortable shifting

- A reliable, field-proven design made by John Deere

- High efficiency and reduced power losses

- A value-spec transmission

- A competitive price

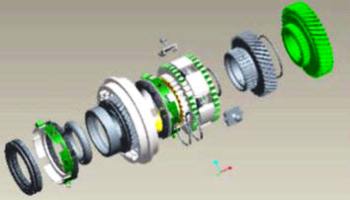

Top-shaft synchroniser

Top-shaft synchroniser

Top-shaft synchroniserAll 5E Series Tractors are fitted with the latest generation of soft-shift transmissions that can be shifted easily even by inexperienced tractor drivers.

What makes this soft-shifting possible is the top-shaft synchroniser. It equalises the speeds of mating gears to allow a clash-free shift while the tractor is in motion.

Inline shifting

Inline shifting

Inline shifting Gear lever positioned close to the SCV joystick

Gear lever positioned close to the SCV joystickQuick-reverse manoeuvres during loader work or at the headland can be performed easily with unique inline shifting.

For inline shifting, second gear is positioned directly on the opposite side of the gear lever, so that the operator can change from the second forward gear into the reverse gear in one line. The second forward gear and the reverse gear have the same speed, which means that inline shifting can be used like a reverser. Due to the top-shaft synchroniser, this integrated reverser solution can be shifted softly.

The gear lever is positioned close to the selective control valve (SCV) joystick in order to change quickly between them when operating the implement or front loader during reversing:

Side-shift levers

Side-shift levers

Side-shift leversComfortable shifting without leaning forward—that is only one of the advantages of the side-shift levers. The range lever is conveniently located on the left hand of the operator. The gear lever is placed on the right-hand side to intuitively find the appropriate gear and range. All gear levers are colour coded in orange for quick familiarisation for inexperienced drivers.

Gear shifting

Gear shifting

Gear shiftingThe gear-shifting lever is ergonomically placed within a hand's reach, which is ideal for the operator. The forward gears and one reverse gear can be shifted in short, crisp lever movements. When in neutral, the gear lever automatically goes into the slot between the second and third gear, which makes shifting very convenient, especially when travelling on a road when gears need to be shifted quickly.

All gears are synchronised.

Range shifting

Range shifting

Range shiftingThree ranges are provided to always find the perfect gear for each single application. High-contact helical gears provide large-tooth contact for great torque transmission capability and quiet operation.

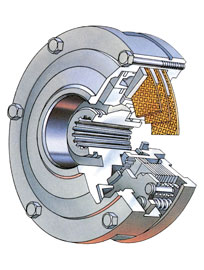

PermaClutch 3 reduces service and maintenance costs

PermaClutch 3

PermaClutch 3PermaClutch is back. Hydraulic, wet, forward, and reverse clutches are permanently lubricated by cooled oil to maximise durability for the long life of a tractor.

The operator does not have to service the PermaClutch 3 on the tractor after 5000 to 6000 hours, which is the average service interval for a dry clutch disc change.

This results in less service and maintenance costs.

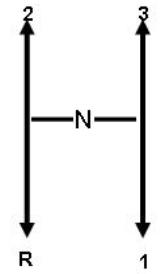

Dual clutch

Dual clutch

Dual clutchReliable and field-proven dual clutches are used in 5E Tractors, one for the power take-off (PTO) and one for driving. The dual clutch ensures independent operation of the PTO, which ensures that the PTO can keep running when the driving clutch is disengaged. This ensures enhanced productivity.

All 5E Series Tractors feature a dry design clutch with a diameter of 280 mm.

Standard and economy PTO

Standard and economy PTO

Standard and economy PTOAll 5E Tractors have the 540 Standard and 540 Economy PTO as standard. The 540 Economy PTO can be driven at only 1705 engine rpm. This allows lower fuel consumption and lower noise emissions, and is more cost efficient. The 540 standard PTO is driven at 2400 engine rpm.

Quick-headland power take-off (PTO) control

Electro-PTO engagement and disengagement on headlands

Electro-PTO engagement and disengagement on headlandsTogether with the electro-reverser, there is also a electro-PTO engagement available. This means when the operator reaches end of field with tiller, the operator just needs to fingertip a soft-push button, which is located close to the raise-lower lever, so the operator can manoeuvre controls quickly for tournament.

Save fuel, reduce noise, and increase engine life in power take-off (PTO) applications with the 540/540 Economy PTO

Shiftable 540/540 Economy PTO (5E) for cab tractors

Shiftable 540/540 Economy PTO (5E) for cab tractors Shiftable 540/540 Economy PTO (5E) for open station tractors

Shiftable 540/540 Economy PTO (5E) for open station tractorsThe 540 Economy PTO option comes in base equipment with the 12F/12R PowrReverser™ transmission.

The 540/540 Economy PTO allows operators to select the engine rpm for reduced fuel consumption, reduced noise levels, reduced vibration, and less wear and tear on the engine, while at the same time keeping the proper 540 rpm at the PTO.

The economy PTO provides 540 rpm to the PTO at 1700 engine rpm. The 540 economy mode is ideal for any PTO application, from running a mower-conditioner to a baler or a cutter, where full engine horsepower is not required.

Operating at lower engine rpm decreases fuel costs up to 30 percent and provides additional productivity by improving the operating experience through enhanced operator comfort from reduced noise and vibration.

A lever allows the operator to simply change between 540 and 540E when conditions merit the opportunity to save fuel without affecting performance.

For heavy-duty operations requiring maximum PTO power, the PTO shift lever is placed in the 540 position, the PTO is engaged, and the engine is run at a rated speed of 2400 rpm. This selection gives 540 rpm to the PTO shaft and delivers the fully advertised horsepower at rated engine speed.

When the tractor is in economy PTO mode, the engine is electronically limited to 1700 rpm, preventing accidental over-speeding of PTO implements and protecting against binding the PTO shaft.

This interlock also prevents accidental shifting of the PTO selector lever at engine speeds above 1700 rpm, which would lead to downtime for fixing implements or drivetrain components.

Specifications

Key Specifications

- Rated with IPM (97/68EC)

- 48 kW (65 hp)

- Max Torque @1800 rpm

- 247 Nm

- Maximum hydraulic flow

- 68.9 L/min

- Maximum lift capacity

- 1800 kg at Hitch Balls