- Used with the W200 Series Self-Propelled Windrower traction units

- 5 m cutting width

- Overshot cross auger improves windrow formation and dry down time

- Open-face converging drum design improves convergence from edges of platform creating consistent, even windrows

Features

Improved performance and durability from rotary cutterbar components

- Large oval disks with free-swinging knives

- Designed to retract when striking solid objects

- Wear caps, crop accelerators, and strippers deliver improved platform performance and lowered cost of operation

Knives and discs

Oval disks with free-swinging knives

Oval disks with free-swinging knives

- Reversible knives double the useful life

- Located at the front of the cutterbar for ease of serviceability

- Knives are identical, making servicing simple

- Disks are made from high strength austempered steel, a heat-treating process that ensures the steel is thoroughly and evenly tempered for good wear characteristics

- Cutting disks rotate toward the center of the platform except for disks 3 and 8, which rotate away from center. The paired rotation of disks 3 and 8 feed crop into the cross auger and help form more uniform edges of the windrow.

Wear caps

Wear caps

Wear caps- Wear caps are installed on each end of the cutting disks (except on the end disks where crop accelerators are used) to increase the wear life of the cutting disks and knife bolt nuts.

- Wear caps are open on the end to prevent debris from packing in close to the nut, making hardware and knives easier to change.

Crop accelerators

Crop accelerator

Crop accelerator- Crop accelerators are added to disks 1, 4, 7, and 10. Accelerators on disks 4 and 7 help to move crop from the diverging area between disks 3-4 and 7-8 and into the conditioning rolls.

- Wear can be determined when a hole becomes visible in the end or the top of the accelerator and replacement is needed (performance may deteriorate before a hole is visible).

- The one-piece design includes a heat-treated steel wear cap that protects the knife bolt nut and the end of the cutting disk.

Rotary strippers

Rotary stripper

Rotary stripper Rotary strippers are bolted to the bottom of the inner converging drum on both the left side and right side of the platform.

Rotary strippers improve crop flow and convergence to the conditioner and minimize crop recirculation; improving windrow formation and crop quality.

Relocating the stripper to the converging drum provides increased wear life of the converging drum and less buildup of dirt and mud on the cutterbar, delivering lower cost of operation and increased uptime.

Rotary strippers are made from high-strength austempered steel for improved wear life.

Easily change out and service the modular-designed cutterbar

The John Deere-patented-design cutterbar is made from individual, diagonal-cut modules. Servicing the modules is easy; the diagonally cut module design allows the modules to be removed individually while leaving the cutterbar attached to the frame. Idler gears transmit power through the cutterbar, increasing life of the platform and improving uptime.

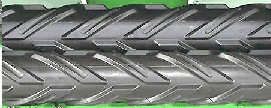

Diagonal-cut modules

Cutterbar module

Cutterbar module- Removing seven bolts (two on each side of the module and three at the rear of the frame) enables a module to be removed from the cutterbar.

- A rubber ring seals each module to the other and enables a common oil reservoir throughout the cutterbar.

- The modules are made of high-strength, nodular iron castings.

Drive components

Cutterbar drive components

Cutterbar drive components - Each module consists of two idler gears and one drive gear. The large-diameter idler gears transmit power from module to module. The idler gears turn at a relatively slow speed for added durability.

- A smaller-diameter pinion drive gear is used only to power the cutting disk. Power is not transmitted from one cutting disk to another except through the large- diameter idler gears.

- Cutterbar modules are interchangeable across the entire cutterbar. Disk rotation is reversible and determined by the quill position (A) when assembling the disk module to the cutterbar. In some conditions, cutting performance can be improved through reversing individual disk rotation.

Maximise performance in varying crops with a choice of conditioners

The 500R offers choices of conditioners to meet customer needs. Varying crop types require different conditioners to deliver maximum performance in terms of window formation, cut quality, and dry down time.

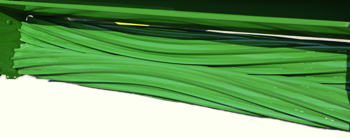

Urethane conditioning rolls

Urethane conditioning rolls

Urethane conditioning rolls- The urethane roll conditioner works well in legumes, especially alfalfa and most all-grass crops. In general, roll conditioners are better suited for thick- stemmed, cane-type, and taller grasses more than 1.5-m (5-ft) tall.

- Molded urethane rolls are formed by a cool molding process that does not distort or warp the steel core of the roll, ensuring the rolls are arrow straight and cylindrical, so they can be accurately spaced close together for uniform conditioning along the length of the roll.

- The intermittent, recessed-cleat design gives more crimping edges for greater pressure per square inch, which results in superior conditioning and faster crop drying.

An adjustable swath board is included with the urethane conditioner roll option.

V-10 steel conditioning rolls

Close-up of V-10 steel conditioning rolls

Close-up of V-10 steel conditioning rolls- The V-10 steel conditioner rolls feature 10 angled flutes arranged in a chevron pattern, or V-pattern, along the length of the steel core.

- Steel rolls offer improved wear life over urethane rolls, particularly in adverse crop conditions.

Advantages of the V-10 conditioner roll over the previous straight-flute design include:

- Deep intermeshing angles for positive feeding and uniform conditioning throughout the entire length of the rolls

- More crimping edges for improved conditioning

- Improved feeding

- Improved windrow formation

An adjustable swath board is included with the V-10 steel conditioner roll option.

Tri-Lobe™ steel conditioning rolls

Tri-Lobe steel conditioning rolls

Tri-Lobe steel conditioning rolls Close-up of Tri-Lobe steel conditioning rolls

Close-up of Tri-Lobe steel conditioning rolls- Tri-Lobe steel conditioning rolls have three intermeshing chevron lobes to crush the length of the stem for improved conditioning and faster drydown. The rolls are manufactured using a patented process.

- The steel material increases wear life, especially in abrasive crops or soil conditions. Durability is a distinct advantage compared to other crusher-style rolls made of rubber or urethane. The chevron design of the rolls gives positive feeding and improved crop flow.

- These rolls are well-suited for use in alfalfa where reduced curing time results in less bleaching of the crop. In heavy, thick-stemmed crops, such as sudan or sudex, the steel construction of the rolls does a very good job of breaking up the nodes on the stems to improve dry down.

Replaceable end shafts

Replaceable end shafts- The shafts on the Tri-Lobe rolls are steel forgings that are then machined. These precision parts have minimal runout, which means the rolls themselves rotate precisely around their axis.

- This precision enables the rolls to be adjusted to a minimum clearance for consistent conditioning along the length of the rolls.

- The machined, forged roll ends are bolted into the core of the Tri-Lobe steel roll. In the event a roll end is damaged, the entire roll does not need to be replaced. Each shaft can be replaced individually, resulting in lower repair costs.

- For serviceability, each roll end has two threaded holes so bolts can be used to pull the shafts from the steel core of the roll.

An adjustable swath board is included with Tri-Lobe conditioner option.

Uniform windrow formation provided by frame, swathboard, and forming shields

The 500R platform delivers John Deere’s latest advancements in windrow formation and uniformity. Even, uniform windrows are critical to reducing dry-down times for dry hay and providing consistent chopping speeds and cut lengths for forage harvesting applications.

Angled frame

Angled frame

Angled frame- The 500R features an angled frame to help merge the crop into the forming shields.

- Merging crop directly behind the conditioning rolls provides a smoother transition to the forming shield, creating a more uniform windrow.

Swathboard

Swathboard

Swathboard- The swathboard is critical to windrow formation as it controls the angle at which the crop contacts the forming shields.

- The welded pipe connecting the adjustment arm to the swathboard provides rigidity, preventing the swath board from bouncing and causing bunching in the windrow.

Forming shield

Forming shield adjustment

Forming shield adjustment  Forming shield attachment

Forming shield attachment- Forming shields are easily adjusted to control the material flow, allowing the operator to match the windrow width to the harvesting requirements.

- The windrow width is adjustable, without the use of tools, from a narrow windrow to a wide, fast-drying swath:

- 4 cm (36 in.) up to 216 cm (85 in.)

- NOTE: The windrow width depends on the crop conditions and type of conditioner.

- Attaching the forming shields to the platform is simple. The shields hang on a cantilevered bolt with spacer and are held in place with a single bolt.

Fixed fluff board

Fixed fluff board

Fixed fluff board

- The fluff board at the rear of the forming shields is fixed in the ideal position to deliver optimal performance in all crop conditions.

Even crop flow from the edges with the overshot cross auger

The overshot cross auger delivers increased performance in windrow formation and cut quality. Improved crop flow from the edges of the platform toward the center provides an even flow into the conditioner creating more uniform windrows. Additionally, crop is lifted off the cutterbar faster for improved cut quality in downed crops and reduced crop recut.

Improved crop flow from edges

Improved crop flow from edges- The overshot cross auger features cupped flighting with a long The cupped shape makes the auger more aggressive in pulling crop from the edges of the platform and the converging drums.

- Moving more crop from the edges of the platform toward the center delivers increased windrow uniformity, helping to reduce drydown time.

Reduced recut

Reduced recut

Reduced recut

- The center flutes of the cross auger have an aggressive edge to help lift crop off the cutterbar and feed it faster into the This improves crop quality in reducing the potential for crop recut.

- Moving crop faster into the conditioning rolls increases the overall capacity of the platform, enabling faster cutting speeds in heavier crop and more acres cut in a

Quick and easy serviceability with lightweight doors, replaceable top sheets

Lightweight plastic doors and bolted top sheets make service quick and easy.

Lightweight plastic doors

Lightweight plastic doors

- Lightweight plastic doors provide resistance to rock damage and are easier to open than original metal doors.

- Bolted top sheets replace an original welded design and can be removed for increased accessibility or replaced in case of rock damage.

Specifications

Key Specs

- Compatibility

- R450, W235, W260

- Cutting width

- 5 m

16 ft

- Cutting height

- 17 to 178 mm

0.6 to 6.7 in.

- Overall width (transport)

- 5 m

16.25 ft

- Weight

- With fluted steel conditioner

2173

4790 lb

With urethane conditioner

2064.3 kg

4551 lb

With Tri-Lobe conditioner

2264 kg

4991 lb

Windrower

- Compatibility

- R450, W235, W260

- Formation

- Adjustable swath board and adjustable forming shields

Impeller Conditioner

- Width

- Diameter

- No. of V-tines

- No. of speeds

- Drive

- Conditioner hood

Urethane Conditioner Rolls

- Width

- 2682 mm

106 in.

- Diameter

- 254 mm

10 in.

- Material

- Urethane

- Surface

- Intermeshing, intermittent recessed cleats

- Speed

- 1000 rpm

- Drive

Steel Conditioner Rolls

- Width

- 2692 mm

106 in.

- Diameter

- 254 mm

10 in.

- Material

- Steel

- Surface

- Intermeshing flutes

- Speed

- 1000 rpm

- Drive

Rotary Disk Cutterbar

- Number of disks

- 10

- Reservoir capacity

- 9.5 L

12 U.S. qt

- Guard angle

- Adjustable; 0 to 8 degree (angle)

Dimensions

- Cutting width

- 5 m

16, 0 ft, in.

- Cutting height

- 17 to 178 mm

0.6 to 6.7 in.

- Overall width (transport)

- 5 m

16, 3 ft, in.

- Weight

- With fluted steel conditioner

4790 lb

With urethane conditioner

4551 lb

With Tri-Lobe conditioner

4991 lb

- Windrower width (depending on crop conditions)

- With roll conditioner

914 to 2159 mm

36 to 85 in.

Additional Information

- Date collected