- 306 kW (410 HP)

- John Deere PowerTech™ 9.0L engine

- e23™ PowerShift or Electric Variable Transmission (EVT)

- Independent Link Suspension (ILS™)

- Our most spacious, comfortable cab yet

Features

Precise power and high efficiency with the Electric Variable Transmission (EVT)

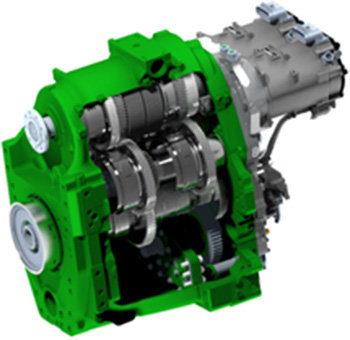

EVT transmission

EVT transmissionStepless transmissions are ideal for overall drivability and those wishing to complete work at precise speeds. Current stepless transmissions are better than ever, but current designs limit true potential. Replacing hydrostatic power with electric power unlocks the ability to monitor the exact load through each major drivetrain component, improves diagnostics, and increases reliability. The EVT transmission delivers efficient power to the ground that John Deere is known for, all with the familiar controls and drive strategy of the IVT. Available as optional equipment on 8R 410, 8RT 410, and 8RX 410 models.

- Improved acceleration between desired ground speeds compared to gearshift transmissions

- Precise infinite speed control from 0.05 to 50 km/h (0.03 to 31 mph)

- Efficient power transfer from the engine to the drawbar results in low fluid consumption while maintaining excellent pulling performance

- Use of electric drive components results in a noticeable reduction in drivetrain noise experienced by the operator compared to the traditional hydraulic motors

- Enhanced reliability with the utilization of proven electric components

- 55 percent reduction in diagnostics requiring tools or a technician for simple in-field troubleshooting

Maximize around-the-clock productivity with visibility packages

Ultimate Visibility package at night (shown on 8R)

Ultimate Visibility package at night (shown on 8R)Visibility is one of the most important attributes of the cab, but it is more than just lighting. In addition to lighting, John Deere visibility packages include mirrors, sunshades, wipers, and camera readiness. Some benefits of the visibility packages include:

- Three package levels to fit your needs – Select, Premium, or Ultimate

- Operate confidently with greater visibility

- Ultimate Visibility package with more light-emitting diode (LED) output and full 360-degree illumination

- Integrated camera capability

| Visibility packages | Select | Premium | Ultimate |

| Lighting | 18 halogen work lights | 18 LED work lights | 22 LED work lights and eight LED convenience lights* |

| Mirrors | Mechanical | Electric, heated | Electric, heated, and telescoping |

| Sunshades | Front | Front, right-hand side, and rear | Front, right-hand side, and rear |

| Wipers | Front and rear | Front, right-hand side, and rear | Front, right-hand side, and rear |

| Cameras | Camera ready | Camera ready | Camera ready** |

*Convenience lights illuminate the corners of the cab for easier entry and exit

**Starting with model year 2022, the Ultimate visibility package is camera ready.

Increase ride comfort during all seasons with 8R suspension options

8R Tractor with cab suspension and air seat

8R Tractor with cab suspension and air seat8R Tractors offer a variety of suspension options to fit your specific field conditions or application. There are three options to choose from on 8R Tractors. An air seat with fixed cab offers a great balance of field and road comfort in an economical package. Cab suspension with an air seat reduces high-frequency vibrations typically associated with road transport. The ActiveSeat™ II equipment is typically chosen for field applications to reduce vertical movement and operator fatigue.

- Air seat with fixed cab offers excellent ride quality in a variety of applications

- Two-post cab suspension with an air seat offers exceptional ride for operators spending time on the road

- ActiveSeat II greatly reduces vertical motion experienced in field applications

- Choice of options is available on all 8R Tractors

Independent-Link Suspension (ILS™) primarily helps deliver power to the ground by maintaining proper tire-to-ground contact through a fully independent system. In addition, ILS greatly improves ride over rough or uneven terrain and drastically decreases power hop.

ILS suspension system

ILS suspension systemMatch demanding applications with hydraulic options

8RX and 8R Tractors in the field

8RX and 8R Tractors in the fieldAll 8 Series Tractors come standard with an 85-cc (5.2-cu in.) hydraulic pump. This pump provides up to 227.1 L/min (60 gpm) hydraulic flow. A dual pump option featuring 85-cc and 35-cc (5.2-cu in. and 2.1-cu in.) displacement hydraulic pumps is available for all 8R and 8RX Tractors. The dual-pump system provides a hydraulic flow of 318 L/min (84 gpm), ideal for running at lower engine speeds. At the rear, up to six selective control valves (SCVs) are available with 1.9-cm (3/4-in.) options.

- Single or dual pump options to fit specific producer applications

- Up to 318 L/min (84 gpm) through the dual pump system on 8R and 8RX Tractors

- Options from four to six factory-installed SCVs

- For maximum flow, 1.9-cm (3/4-in.) SCV couplers are available factory and field installed

A power beyond option is available on all models, and a high-capacity take-out oil reservoir (on 8R Tractors only) is also available for high-demand applications.

8RX Tractor with power beyond

8RX Tractor with power beyondComfort and convenience to fit the needs of any operator

Ultimate Comfort and Convenience package (shown on 8R Tractor)

Ultimate Comfort and Convenience package (shown on 8R Tractor)Comfort and Convenience packages

When you reach a 40-hour week by Wednesday, you're logging some serious hours in the cab. Spend that time in the refreshed and refined John Deere cab, and experience a quiet, comfortable ride with unrivaled visibility and convenience.

- Three package levels to fit your needs – Select, Premium, or Ultimate

- CommandARM™ console that puts everything you need within reach

- Plenty of storage

- Work comfortably during long days in the field with an automotive-style seat

- Keep electronics powered throughout the day with a variety of outlets

| Comfort and Convenience packages | Select | Premium | Ultimate |

| Seat |

|

|

|

| Infotainment |

|

|

|

| Business band ready | X | X | X |

| Four USB and one 12-V outlet | X | X | X |

| Dual tilt column | X | X | X |

| Footrests | --- | X | X |

| Refrigerator | --- | X | X |

| 120-V/300-W three-prong outlet | --- | X | X |

| Carpeted floor mat | --- | --- | X |

| Leather-wrapped steering wheel | --- | --- | X |

Bluetooth is a trademark of Bluetooth SIG, Inc.

Increase productivity with John Deere integrated solutions

Maximizing uptime using connectivity and technology

Maximizing uptime using connectivity and technologyYour needs and success are the focus of John Deere. John Deere makes it easy for you to benefit from having a connected tractor in your operation. All tractors come standard with JDLink™ telematics system and customers can turn on connectivity in the John Deere Operations Center™ application. With a StarFire™ 6000 Integrated Receiver* and Generation 4 CommandCenter™ Display, you can easily step right into advanced technology. If you’re an advanced tech user, you’ll enjoy the benefits of a highly intelligent machine connected to a full suite of solutions on the most open platform in the industry. Advantages of a connected machine include:

- StarFire 6000 Integrated Receiver eliminates all setup, installation, and global positioning system (GPS) calibrations

- AutoTrac™ assisted steering guides the machine with accuracy in a variety of field conditions

- Automation is an option with some applications

- John Deere Connected Support™ is a proactive service approach to improve service efficiency and reduce machine downtime

- JDLink gives you access to information anytime, anywhere, to make data driven decisions with John Deere Operations Center and Documentation

The technology and connectivity in John Deere tractors allow you to optimize productivity, increase uptime, and boost profits with machine information from any device, anywhere.

*NOTE: Ordering is temporarily unavailable for the StarFire 6000 Integrated Receiver. John Deere is diligently working to resolve this issue. Please watch the Price Pages and the announcements in the Sales Manual for updates. We apologize for any inconvenience.

|  |  |

| StarFire 6000 Integrated Receiver | AutoTrac | JDLink |

Base equipment:

Optional equipment:

| Base equipment:

Optional equipment:

| Base equipment:

|

*Available with Premium Activation 3.0

**Available with Automation Activation 3.0

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

Connected Support technology

Connected Support technologyWhen you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

Specifications

Key Specs

- Engine description

- John Deere PowerTech™ 9.0 L (B20 diesel compatible)

- Engine displacement

- 9.0 L

549 cu in.

- Rated engine power

- ECE-R120: 302 kW

410 hp

- Maximum engine power

- ECE-R120: 326 kW

443 hp

- Rated PTO power (hp SAE)

- 231 kW

310 hp

- Maximum PTO power

- Transmission type

- Standard: e23™ PowerShift™ with Efficiency Manager™ 40K, 40 km/h

24.9 mph

Optional: e23 PowerShift with Efficiency Manager 50K, 50 km/h

31 mph

John Deere eAutoPowr™ EVT 40K, 0.05-42 km/h

0.03-26 mph

John Deere eAutoPowr EVT 50K, 0.05-50 km/h

0.03-31 mph

- Hydraulic pump rated output

- Standard: 85-cc pump: 227.1 L/min

60 gpm

Optional: 85-cc plus 35-cc dual pump: 318 L/min

84 gpm

- Rear hitch category (SAE designation)

- Standard: Category 4N/3 standard lift at 610 mm (24 in.) behind hitch point: 9072 kg

20,000 lb

Optional: Category 4N/3 at 610 mm (24 in.) behind hitch point: 6803 kg

15,000 lb

- Base machine weight

- ILS™/e23: 12,700 kg

28,000 lb

- Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628)

- Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628)

Engine Specifications

- Description

- John Deere PowerTech 9.0 L (B20 diesel compatible)

- Engine type

- In-line six, four valve

- Engine family

- MJDXL09.0333

- Rated speed

- 2100 rpm

- Aspiration

- Dual turbochargers, variable geometry turbo with fixed geometry turbo in series; air-to-air aftercooling and cooled exhaust gas recirculation

- Cylinders liners

- Wet-sleeve

- Emission level

- Final Tier 4

- After treatment type

- Diesel oxidation catalyst (DOC)/diesel particulate filter (DPF)/selective catalytic reduction (SCR)

- Displacement

- 9.0 L

549 cu in.

Engine Performance

- Rated power

- ECE-R120: 302 kW

410 hp

- Rated PTO power (hp SAE)

- 231 kW

310 hp

- Maximum PTO power

- Intelligent Power Management (IPM)

- Power boost

- 8 percent

- Maximum engine power

- ECE-R120: 326 kW

443 hp

- Engine peak torque

- At 1600 rpm: 1851 Nm

1365 lb-ft

- Drawbar power

- PTO torque rise

- 40 percent

- Fuel injection system and control

- Air cleaner type

- Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628)

- Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628)

Transmission

- Type

- Standard: e23 PowerShift with Efficiency Manager 40K, 40 km/h

24.9 mph

Optional: e23 PowerShift with Efficiency Manager 50K, 50 km/h

31 mph

John Deere eAutoPowr EVT 40K, 0.05-42 km/h

0.03-26 mph

John Deere eAutoPowr EVT 50K, 0.05-50 km/h

0.03-31 mph

- Reverser

- Clutch; wet/dry

- Creeper

Hydraulic System

- Type

- Closed-center, pressure/flow compensated system with load sensing

- Pump rated output

- Standard: 85-cc pump: 227.1 L/min

60 gpm

Optional: 85-cc plus 35-cc dual pump: 318 L/min

84 gpm

- Available flow at a single rear SCV

- 1.3-cm (1/2-in.) couplers: 132 L/min

35 gpm

1.9-cm (3/4-in.) coupler: 159 L/min

42 gpm

- Available flow at front SCVs

- 96 L/min

25 gpm

- Number of rear selective control valves (SCVs)

- Standard: 1.3-cm (1/2-in.) ISO couplers: 4

Optional: 1.3-cm (1/2-in.) ISO couplers: 5 and 6 available

1.9-cm (3/4-in.) ISO coupler: 1

- Number of mid selective control valves (SCVs)

- Number of front selective control valves (SCVs)

- Joystick SCV control

- Auxiliary hydraulic features

- SCV control

- Electronic

Rear Hitch

- Hitch draft control load sense type

- Remote control valves available

- Hitch category (SAE designation)

- Standard: Category 4N/3 standard lift at 610 mm (24 in.) behind hitch point: 9072 kg

20,000 lb

Optional: Category 4N/3 at 610 mm (24 in.) behind hitch point: 6803 kg

15,000 lb

- Maximum lift capacity behind lift points

- Standard (at 610-mm [24-in.] behind hitch point): 12,124 kg

26,729 lb

- Lift capacity at standard frame

- Sensing type

- Electrohydraulic

- Rear axle differential lock

- Electrohydraulic

Drawbar

- Drawbar category

- Standard: Category 4

Optional: Category 4 with heavy-duty support

- Maximum vertical load

- Dependent on drawbar position: 1837 to 2700 kg

4050 to 6000 lb

Optional: 2,245 kg

4,950 lb

4,990 kg

11,000 lb

Rear Power Take Off (Pto)

- Type

- Independent

Standard: 44 mm (1.75 in.) 20-spline, 1,000 rpm

Optional: 44 mm (1.75 in.) 20-spline, 1,000 rpm/1,000E rpm

- Engine rpm (at rated PTO speeds)

- e23 PowerShift: 1,000 PTO rpm at 1,995 engine rpm, 1,000 ECO PTO at 1,590 engine rpm, 540 PTO rpm at 1,810 engine rpm

- Economy PTO speeds

- Reverse PTO speeds

- Multispeed PTO option availability

- Available: 45-mm (1.75-in.), 1000-rpm and 1000E economy rpm PTO, in-cab shiftable

- Ground speed PTO option availability

- PTO actuation

- Electrohydraulic with adjustable modulation

Front Hitch

- Category

- Category 3N

- Electric power

- Standard lift capacity

- Category 3N ground-engaging front hitch: 5200 kg

11,464 lb

- Front power take-off (PTO)

- 44 mm (1.75 in.) 20 spline, 1000 rpm

35 mm (1.375 in.) 21 spline, 1000 rpm

35 mm (1.375 in.) 6 spline, 1000 rpm (available dependent on location)

- PTO speed

- 1,000 PTO rpm at 2000 engine rpm

Rear Axle

- Type

- Standard: Rack-and-pinion, double flat, or flange axles

Optional: short, double flat axle with single taper hub: Diameter: 120 x 2550 mm

4.72 x 100.4 in.

Long, double flat axle with single taper hub: Diameter: 120 x 3010 mm

4.72 x 118.5 in.

- Final drive type

- Inboard planetary three pinion

- Differential controls

- Axle type

- Brakes, type and control

- Rear differential lock

- Full-locking electrohydraulic

- Load rating

Front Axle

- Type

- Standard: ILS

Optional: 1500 Series MFWD

- Front axle differential lock

- 1500 Series MFWD: Full-locking electrohydraulic

ILS: Full-locking electrohydraulic

- Load rating

Tires

- Rear

- Wheel tread range

- 1500 Series MFWD: 1524-3657 mm

60-144 in.

ILS: 1524-3657 mm

- Turning radius with brakes

- Turning radius without brakes

- 1500 with 420/850R34 Group 43 tires at 182.9-cm (72-in.) spacing: 5.71 m

18.7 ft

ILS with 480/70R34 Group 43 tires at 184.2-cm (72.5-in.) spacing: 6.45 m

21.2 ft

- Central Tire Inflation System (CTIS)

- Optional

- Front

Tracks

- Tread spacing

- Drive type

- Track width

- Mid-rollers

Brakes

- Primary brake (foot brake)

- Secondary brake

- Park lock

- MFWD braking

- Front axle brakes

- Auxiliary brakes

- Hydraulic trailer brakes

- Pneumatic trailer brakes

Electrical System

- Alternator size

- Standard: 200 amp

Optional: 330 amp

- Battery options

- 12 V

- Working lights

- Standard: 18 halogen

Available: 18 LED

22 LED

- Type of bulb in headlight (Halogen, Zenon, LED)

- Standard: halogen, 65 W

Available: LED

- Type of bulb in beacon (Halogen, Zenon, LED)

- dB(A) rating for backup alarm

- Total cold cranking amps

- 1,850 CCA

Operator Station

- Rollover protective structure, OOS

- Seat

- Degree of seat swivel, left hand

25 degree (angle)

Degree of seat swivel, right hand

40 degree (angle)

Standard: air suspension

Optional: ActiveSeat™ II

- Cab suspension

- Optional

- Instructional seat

- Standard

- Display

- Standard: 4600 Generation 4 CommandCenter™: 25.4 cm

10 in.

- Radio

- Standard: AM/FM stereo with weatherband, remote controls, auxiliary input jack, four speakers and external antenna

- Inner cab volume

- 3.24 m3

114 cu ft

- dB(A) rating

- Cab glass area

- 6.52 m2

70.18 sq ft

- Safety glass rating

- Front visibility

Dimensions

- Wheelbase

- MFWD: 3,080 mm

121.3 in.

ILS: 3,050 mm

120.1 in.

- Overall width

- Overall length

- 6,636 mm

261.3 in.

- Overall height

- Drawbar clearance

- 376 mm

14.8 in.

- Front axle center

- MFWD: 686 mm

27 in.

ILS: 590 mm

23.2 in.

- Approximate shipping weight, Open;Cab

Weight

- Base machine weight

- ILS™/e23: 12,700 kg

28,000 lb

- Maximum ballast level

- 20,000 kg

44,100 lb

- Maximum permissible weight

- 20,000 kg

44,100 lb

Capacities

- Crankcase oil volume

- 1500 MFWD: 27.6 L

7.3 U.S. gal.

ILS: 25.8 L

6.8 U.S. gal.

- Fuel tank

- 727 L

192 U.S. gal.

CTIS: 651 L

172 U.S. gal.

EVT: 651 L

- Diesel exhaust fluid (DEF) tank

- 37.2 L

9.8 U.S. gal.

- Cooling system

- 42.3 L

11.2 U.S. gal.

EVT: 46.9 L

12.4 U.S. gal.

- Transmission-hydraulic system

- 1500 MFWD: 184.6 L

48.8 U.S. gal.

ILS: 207.2 L

54.7 U.S. gal.

Serviceability

- Interval for engine oil change

- 500 hours

- Interval for hydraulic/transmission oil change

- 1,500 hours

- Interval for engine coolant change

- 6,000 hours

Precision Ag

- Guidance

- Integrated AutoTrac™

- Telematic

- JDLink™ hardware standard, activations, and Ethernet harnesses (availability dependent upon destination)

- Remote diagnostics

- JDLink hardware standard

Miscellaneous

- AutoTrac ready

- ISOBUS ready

- CommandCenter video inputs

- Immobilizer

- Side slope rating

- Uphill/downhill slope rating

- Country of manufacture

- USA

Steering

- Type

- Standard: Hydraulic power-steering with electric pump back-up

Optional: ActiveCommand Steering 2 (ACS™ 2) with electronic backup pump

- Date collected

- 12 January 2022