- Wheelbase 2098 mm

- Turning radius 3.6 m

- Fuel tank capacity 73 L

Features

Tailored to fit: John Deere specialty solutions

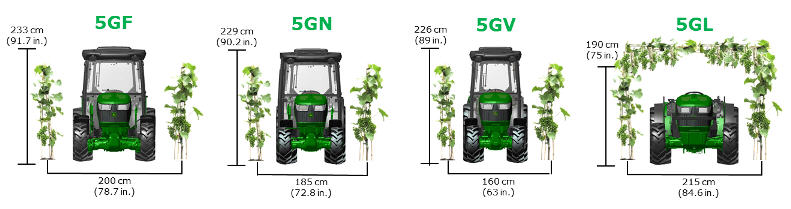

The 5G Stage IIIA Specialty Series provide the most comprehensive range of solutions for specialty crop farming.

While the 5GF provides excellent performance in wide vineyards and orchards, the 5GN is the solution of choice for narrower row widths until 185 cm (72.83 in.). Both the 5GF and the 5GN feature an extra wide cab of 120 cm (47.2 in.).

A low-profile solution (5GL) and a super-narrow vineyard tractor with a minimum overall width of 1.03 m (40.4 in.) are now offered.

The super-narrow 5GV Series is built to operate in vineyards with a minimum working width of 160 cm (63 in.). The 5GV Series cab, with an overall width of 100 cm (39.37 in.), is designed to pass between narrow vineyard rows.

In terms of tractor width, the 5GL (Low-Profile) Series is based on the 5GF Series. With the lowest possible height from the ground to the top of the hood 1234 mm (48.6 in.) and rear fenders 1089 mm (42.9 in.) the 5GL is a real low-profile solution.

Overview minimum working widths and heights:

5G Specialty Series: minimum working widths and heights

5G Specialty Series: minimum working widths and heights5G Specialty Series basic feature overview:

Feature overview | 5GF | 5GN | 5GV | 5GL |

| 100 hp (74 kW) 4-cylinder / 4.5 L (1.05 gal.) | 5100GF | 5100GN | Not available | Not available |

| 85 hp (65 kW) 4-cylinder / 3.2 L (0.8 gal.) | 5085GF | 5085GN | 5085GV | 5085GL |

| 75 hp (55 kW) 4-cylinder / 3.2 L (0.8 gal.) | 5075GF | 5075GN | 5075GV | 5075GL |

| Two-wheel drive (2WD) / four-wheel drive (4WD) | Available | Available | Available | Only 4WD |

| Cab/open operator station (OOS) | Available | Available | Available | Only OOS |

John Deere value

Performance: Tailored to fit – the ideal match for all kinds of specialty plantations.

Low-profile dimensions (5GL)

The 5GL (low profile) meets users’ needs for operating in low vineyards, low orchards, or glass houses due to its low-profile shape. Relative to the ground, the tractor comes with the lowest possible height to hood, to operator’s seat, and to rear fenders to avoid interference with low-hanging crops or branches.

The 5GL compactness offers the right envelope and a low center of gravity; ideal for working in hilly and height-restricted conditions.

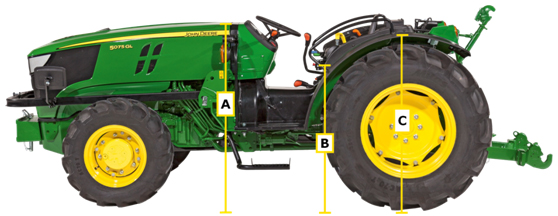

5GL dimensions

5GL dimensionsDimensions and weights 20-in. (508-mm) rear tyres | 5075GL | 5085GL |

Height to hood (A) | 1234 mm (48.6 in.) | |

Height to operator’s seat (B) | 953 mm (37.5 in.) | |

Height to rear fender (C) | 1089 mm (42.9 in.) | |

Tyre sizes | 5075GL | 5085GL |

Front axle tyre sizes | 260/70 R16 | |

Rear axle tyre sizes | 380/70 R20 | |

Dimensions and weights 24-in. (610-mm) rear tyres | 5075GL | 5085GL |

Height to hood (A) | 1269 mm (50 in.) | |

Height to rear fender (B) | 1160.9 mm (45.7 in.) | |

Height to operator’s seat (C) | 988 mm (38.9 in.) | |

Tyre sizes | 5075GL | 5085GL |

Front axle tyre sizes | 280/70 R16 | |

Rear axle tyre sizes | 360/70 R24 | |

Low-profile shape

Rear fenders without control levers

Rear fenders without control leversThe 5GL features rear fenders without control levers, which could interfere with branches or crops.

Foldable lights

Foldable lights Foldable license plate holder

Foldable license plate holderThe foldable mid-mounted rollover protective structure (ROPS), which comes in base with the new 5GL Series, provides the minimal height in working conditions.

In order to further match low-profile requirements the 5GL Series features foldable mirrors, lights, and license plate holder.

Optimised package ex factory

5GL Tractor

5GL TractorThe 5GL can be ordered with a customised range of options:

- Available in 75 hp or 85 hp open operator station

- Standard with four-wheel drive (4WD)

- 24 forward/24 reverse (24F/24R) transmission

- Open-center hydraulic system with a tandem pump generating an output of 94 L/min. (25 gal./min.)

- Two-speed power take-off (PTO) 540/540E and 540/1000 with optional ground drive power take-off (PTO)

- 2.6-ton (5732-lb) lift capacity

- All in a compact package with a 67-L (17.7-gal.) fuel tank

The 5GL is an optimised package coming ex factory with the features suited for power demanding applications in narrow and very low working environments.

John Deere value

Performance: Supported by the low-profile shape, the dimensions of the 5GL Series meet operators’ needs without the need of further modifications. This solution allows the tractor to operate in low vineyards, low orchards, or glass houses without the risk of damaging crops or low hanging branches.

Comfortable cabin versions (5GF, 5GN, 5GV)

The cabs for the 5GF, 5GN, and 5GV Series have been redesigned to fit the needs of the different specialty producers. The 5GF and the 5GN Series feature an extra-wide cab at 120 cm (47.2 in.). The 5GV Series cab with an overall width of 100 cm (39.4 in.), is designed to operate between narrow vineyard rows.

Wide and narrow cab

Wide and narrow cab

The 5GF and the 5GN Series feature a 120-cm (47.2-in.) extra-wide cab. The ergonomic layout is easy to see and use inside the cab. Without any other obstacles than the tunnel and a wide door of 945 mm (37.2 in.), the operator is able to conveniently enter and exit the cabin. With a distance of 560 mm (22.05 in.) between the right- and left-hand side consoles and a play of 285 mm (11.2 in.) between seat and steering wheel, the 5GF and 5GN Series provide one of the most comfortable cabs in the specialty tractor market.

Wide 5GF and 5GN cab

Wide 5GF and 5GN cab

The cabin of the 5GV Series provides the operator the same level protection while working in the rows or driving on the road. The overall width of the cab of 100 cm (39,37 in.), is designed to operate between narrow vineyard rows without interferences with crops or branches.

Narrow 5GV cab

Narrow 5GV cab

All the controls are grouped together based on function and logically placed for easy, comfortable use throughout the day. Both cabin versions of the 5GF, 5GN, and 5GV can be equipped with optional electrohydraulic (EH) selective control valve (SCV) controls providing a high level of comfort:

EH SCV option shown on the 5GF

EH SCV option shown on the 5GF

| Code | Description | Information | Availability |

| 3341 | Four EH SCVs | Two DA SCVs (detent in pressure + detent in float)

| 5GF, 5GN, 5GV |

In addition, the comfort implement control option is available for the 5GF and 5GN Series which enables the electrohydraulic steering and guidance of rear attached implements in narrow rows.

Comfort implement control shown on the 5GF

Comfort implement control shown on the 5GF

| Code | Description | Information | Availability |

| 8459 | Comfort implement control |

| 5GF, 5GN |

| 8460 | Comfort implement control |

| 5GF, 5GN |

John Deere value

Performance: The redesigned cabin of the 5GF and 5GN is in terms of comfortable seating, entering, and exiting the cabin one of the most comfortable cabins in the specialty tractor market. The narrow cabin of the 5GV Series offers protection for the operator and the crops in the rows. Including premium controls, the new 5G Specialty Series offers comfortable productivity all day.

Powerful Stage IIIA engines

The 5G Specialty Series Tractors are equipped with powerful Stage IIIA diesel-only engines.

Powerful Stage IIIA engines

Powerful Stage IIIA engines Powerful Stage IIIA engines

Powerful Stage IIIA enginesThe higher 100 hp models are equipped with a robust 4-cylinder, 4.5-L (1.05-gal.) displacement engine. The lower 75 hp and 85 hp models offer a compact 4-cylinder, 3.2-L (0.8-gal.) engine offers real versatility and performance for all kinds of specialty operations.

| Engine overview | 5GF | 5GN | 5GV | 5GL |

| 100 hp (74 kW) 4-cylinder / 4.5 L (1.05 gal.) | 5100GF | 5100GN | Not available | Not available |

| 85 hp (65 kW) 4-cylinder / 3.2 L (0.8 gal.) | 5085GF | 5085GN | 5085GV | 5085GL |

| 75 hp (55 kW) 4-cylinder / 3.2 L (0.8 gal.) | 5075GF | 5075GN | 5075GV | 5075GL |

Supporting the narrow and low dimensions of the 5GV and 5GL Series

The narrow width of the 5GV Series and the low height of the 5GL Series require a compact engine solution. The compact 3.2-L (0.85 gal.) engine supports the envelope of the 5GL Series going underneath pergola vineyards and the 5GV Series entering super narrow vineyards.

Performance - made to measure

The engine ensures a high productivity under manifold working conditions. With a torque rise of 40 percent of the 5075G Specialty Series, 30 percent of the 5085G Specialty Series and 32 percent of the 5100GN/GF, the engine ensures the appropriate performance for versatile operations.

Less maintenance

Service intervals for the engine have increased by 100 percent from 250 hours to 500 hours. This decreases maintenance costs and increases time in the field.

John Deere value:

Performance: The powerful Stage III engines support the narrow and low machine envelope of the new 5G Specialty Series and offer a high torque rise which provide the right dimensions and a high performance.

Cost of operation and Uptime: With an increased engine service interval the customer is able to reduce maintenance cost while spending more time in the field.

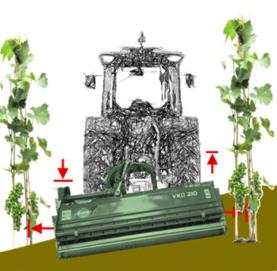

Outstanding power take-off (PTO) efficiency

PTO efficiency shown on the 5GF

PTO efficiency shown on the 5GF PTO efficiency shown on the 5GV

PTO efficiency shown on the 5GVThe 5G Specialty Tractors 5GF, 5GN, 5GV, and 5GL can be equipped with electrohydraulic or mechanically engaged 540/540E or 540/1000 PTO either with or without ground-drive PTO.

As an average, orchard or vineyard producers use a specialty tractor about 40 percent for PTO applications. Efficient PTO performance is a very important aspect of specialty tractors.

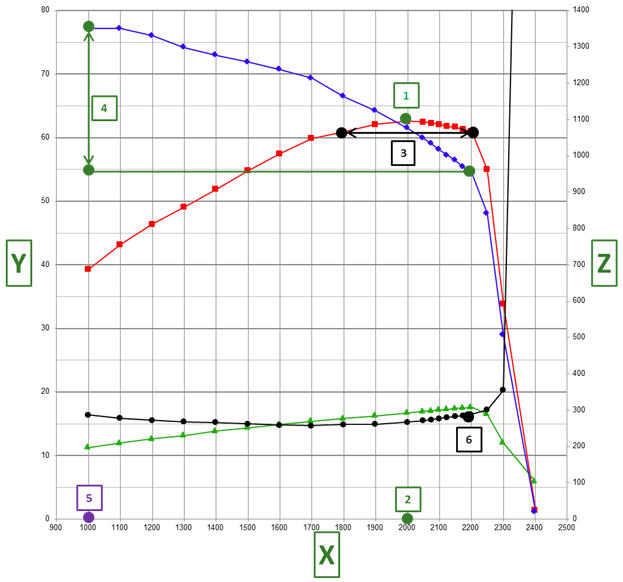

The John Deere 5100GF has been tested in the dynamometer (dyno) with engineering support in order to prove the high PTO efficiency with the following results:

| PTO test measurements | John Deere 5100GF |

| Constant power range (rpm) | 400 |

| PTO torque reserve (percentage) | 41,5 |

| Fuel consumption (g/kW/h) | 288,9 |

The high constant power range of 400 rpm, torque reserve of 41.5 percent, and the low fuel consumption during PTO applications prove that specialty users can rely on a strong PTO performance.

The number of horsepower provided by the engine to the PTO-shaft is reduced through the transmission. The smaller the horsepower loss from the engine to the PTO, the higher the efficiency of the transmission. The following values measured at the PTO shaft prove that the John Deere 5G Specialty Series provides a high transmission efficiency and therefore real horsepower needed for the high amount of PTO applications a specialty producer is performing throughout the year:

| PTO test measurements | John Deere 5100GF |

| Rated Engine hp (kW) at 2200 rpm | 100 (74) |

| PTO hp (kW) | 81,8 (61) |

| Power losses hp (percentage) | 18,2 (18,2 percent) |

PTO power curve 5100GF

PTO curve

PTO curve

| Legend axis | ||

| X | Fuel rate [kg/h] / power [kW] | |

| Y | Engine speed [rpm] | |

| Z | Brake specific fuel consumption (BSFC) [g/kWh] / PTO torque [Nm] | |

| Legend lines | ||

| Power | |

| Fuel rate | |

| Torque | |

| BSFC | |

| Legend values | Values | |

| 1 | Maximum PTO power | 62,6 kW |

| 2 | Engine rpm at maximum power | 2,000 rpm |

| 3 | Constant power range | 400 rpm |

| 4 | Torque reserve | 41,5% |

| 5 | Engine rpm at maximum torque | 1,000 rpm |

| 6 | BSFC at rated speed | 288,9 g/kW/h |

| Code | Description | Information | Availability |

| 3820 | Mechanical actuation 540 / 540E rpm | Shiftable with GD PTO with PTO shaft cover with safety start switch | 5GF, 5GN, 5GV, 5GL |

| 3821 | Mechanical actuation 540 / 1000 rpm | Shiftable with GD PTO with PTO shaft cover with safety start switch | 5GF, 5GN, 5GV, 5GL |

| 3822 | Mechanical actuation 540 / 540E rpm | Shiftable without GD PTO with PTO shaft cover with safety start switch | 5GF, 5GN, 5GV, 5GL |

| 3823 | Mechanical actuation 540 / 1000 rpm | Shiftable without GD PTO with PTO shaft cover with safety start switch | 5GF, 5GN, 5GV, 5GL |

| 3824 | Electrohydraulic actuation 540 / 540E rpm | With GD PTO with PTO shaft cover with safety start switch | 5GF, 5GN, 5GV |

| 3825 | Electrohydraulic actuation 540 / 1000 rpm | With GD PTO with PTO shaft cover with safety start switch | 5GF, 5GN, 5GV |

| 3826 | Electrohydraulic actuation 540 / 540E rpm | Without GD PTO with PTO shaft cover with safety start switch | 5GF, 5GN, 5GV |

| 3827 | Electrohydraulic actuation 540 / 1000 rpm | Without GD PTO only available with Power Reverser transmission (code 3800) with PTO shaft cover with safety start switch | 5GF, 5GN, 5GV |

John Deere value

Performance and Cost of operation: Versatile PTO options which are designed to deliver outstanding power to PTO driven implements in the field - high constant power range, high torque reserve, low fuel consumption and a low power loss.

Electrohydraulic (EH) selective control valve (SCV)

The optional electrohydraulic system consists of three hydraulic pumps and four electrohydraulic rear SCVs.

EH SCV option

EH SCV option

The optional electrohydraulic SCV system consists of three hydraulic pumps and four electrohydraulic rear SCVs with the following hydraulic performance:

| Hydraulic performance [75 hp and 85 hp at 2300 rpm] | 5075GF | 5085GF | 5075GN | 5085GN | 5075GV | 5085GV |

| Steering and transmission (L/min) | 28.9 L/min (7.63 gal./min) | |||||

| Second pump - SCV and hitch (L/min) | 64.7 L/min (17.09 gal./min) | |||||

| Third pump - SCV and hitch (L/min) | 28.9 L/min (7.63 gal./min) | |||||

| Total hydraulic flow (L/min) | 122.5 L/min (26.95 gal./min) | |||||

The 4.5-L (1.05-gal.) engines of the 100 hp models are rated at 2200 rpm. The values for the hydraulic flow per minute are different compared to the lower horsepower models equipped with the 3.2-L (0.8-gal.) engine.

| Hydraulic performance [75 hp and 85 hp at 2300 rpm] | 5100GF | 5100GN |

| Steering and transmission (L/min) | 24.9 L/min (6.58 gal./min) | |

| Second pump - SCV and hitch (L/min) | 56.5 (14.93 gal./min) | |

| Third pump - SCV and hitch (L/min) | 26 (6.87 gal./min) | |

| Total hydraulic flow (L/min) | 107,4 L/min (28.37 gal./min) | |

EH SCV controls shown on the 5GF

EH SCV controls shown on the 5GF

The electrohydraulic SCV option comes with additional joystick and fingertip controls for more ergonomic and effective implement control. During hydraulic operations with a leaf cutter, the joystick control provides maximum precise control.

Also located at the right-hand console, the flow controls for SCV No. 1–4 and the time controls for SCV No. 1 and 2 the performance of the hydraulic-driven implement(s) can be adjusted by turning the rotary knobs.

Maximum comfort during hydraulic applications shown on the 5GV

Maximum comfort during hydraulic applications shown on the 5GV

The EH SCV controls enable maximum comfort even during the most challenging and complex hydraulic applications.

| Code | Description | Information | Availability |

| 3341 | Four EH SCVs | Two DA SCVs (detent in pressure + detent in float)

| 5GF, 5GN, 5GV |

John Deere value

Performance: Adequate hydraulic flow to SCVs and rockshaft and precise, comfortable control for power-demanding implements – high performance and precision in the rows.

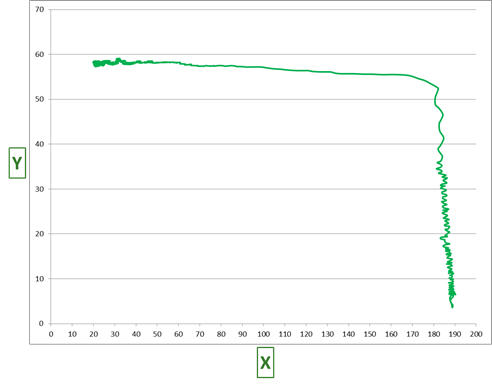

Constant hydraulic performance

The hydraulic system of the John Deere 5100GF has been tested in hydraulic test bench with engineering support in order to prove the outstanding hydraulic performance of the 5G Specialty Series. Usually, as the pressure at the selective control valve (SCV) increases, the hydraulic performance (L/min) decreases.

The following table shows the measured flow loss at various pressure points and clearly proves that the 5G Specialty Series provide a constant hydraulic flow even at high pressure points:

| Maximum flow rate | No load | 100 bar (1450 psi) | 150 bar (2175 psi) | 175 bar (2538 psi) |

| 5100GF | 58 L/min (15.3 gal./min) | 58 L/min 915.3 gal./min) | 55,6 L/min (14.7 gal./min) | 54 L/min (14.3 gal./min) |

The constant hydraulic flow even at such high pressure points at 175 bar provides a high turning cycle for power demanding hydraulic implements or for the simultaneous usage of various hydraulic implements at the same time.

Hydraulic flow rate 5100GF

Hydraulic curve

Hydraulic curve| Axis legend | |

| X | SCV outlet [Bar] |

| Y | SCV outlet [L/min] |

John Deere value

Performance: Constant hydraulic performance even at high working pressure leads to reliable hydraulic performance in the field.

Optional extra lift capacity (5GF, 5GN)

The heavy-duty 3-point hitch design on the 5G Specialty Series provides a standard maximum lift of more than 2590 kg (25.4 kN) at balls.

Optional additional lift cylinders are available for the 5GF and 5GN Series which increases the maximum lift capacity by 510 kg (1124.4 lb) (5 kN) to 3100 kg (6834.3 lb) (30.4 kN).

Optional extra lift capacity shown on the 5GN

Optional extra lift capacity shown on the 5GNThe Category 1 and 2 3-point hitch, in combination with the increased lift capacity, allows the 5G Specialty Series to be adapted to a wide variety of implements and applications.

| Code | Description | Information | Availability |

| 4012 | Mechanical rockshaft | Includes additional lift cylinder (maximum lift capacity at ball ends: 3.1 tons) | 5GF, 5GN |

| 4031 | Electronic rockshaft | Includes:

| 5GF, 5GN |

John Deere value

Performance: Higher lift capacity for a wider variety of implements and strong performance means real versatility.

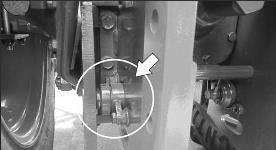

New comfort implement control (5GF, 5GN)

In order to guide rear attached implements into narrow rows even on slopes, the 5G Specialty Series provide the comfort electrohydraulic implement controls. Electrohydraulic lateral and tilt control including swing and lock function.

Functionality of the comfort implement control

Functionality of the comfort implement control

Those functions are enabled through the hydraulic deport block at the rear hitch, which fixes the sway blocks or moves the implement electrohydraulically:

Hydraulic deport block

Hydraulic deport block

The hydraulic deport block gets activated by the following switches at the right-hand console:

Comfort implement control shown on the 5GF

Comfort implement control shown on the 5GF

| A | Floating adjustment |

| Blocking adjustment | |

| B | Left-hand side adjustment |

| Right-hand side adjustment | |

| C | Retract the hydraulic cylinder |

| Extend the hydraulic cylinder |

Without occupying any rear selective control valve (SCV), the rear-mounted implement can be guided comfortably from the operator’s seat by depressing one of the three corresponding switches in the right-hand side console.

Comfort implement control shown on the 5GF

Comfort implement control shown on the 5GF

Any application with a rear attached implement can be executed in a more precise and efficient way by moving the draft links either lateral, adjusting the implement on uneven ground conditions, or by locking the draft links once the ideal position of the implement has been found.

| Code | Description | Information | Availability |

| 8459 | Comfort implement control |

| 5GF, 5GN |

| 8460 | Comfort implement control |

| 5GF, 5GN |

John Deere value

Performance: The comfort implement control option allows the specialty producer to comfortably steer and guide rear attached implements in narrow rows. The implement can be moved electrohydraulically with a touch of a button in the cabin.

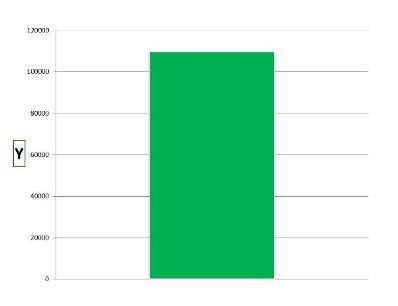

Effortless serviceability

Effortless serviceability

Effortless serviceabilityUnder the umbrella of the internal benchmarking activities, JDWM Customer Support performed a serviceability study with the John Deere 5085GF Series.

The serviceability study has been executed according to the directive SAE J817 Engineering Design Serviceability Guidelines - Construction and Industrial Machinery - Maintainability Index - Off-Road Work Machines.

Serviceability score points

Serviceability score points| Axis legend | Value 5GF | |

| Y | Score SAE 753 | 8905 |

According to SAE 753, the John Deere 5G Specialty Series provides an outstanding serviceability score taking the following parameters into account:

- Location and access to service points

- Kind and number of service operations

- Labor time behind each maintenance activity

John Deere value

Cost of operation and Uptime: Convenient maintenance and service with less labor time leads to spending more time in the field.