- 12,20 m Cutting width

- 1200 mm Draper belt width

- 72 - 228 m/min Draper Speed

- Dual Knife Drive with 2080 cuts/min

- 1200 mm Table length

Features

Harvest more acres per day

X Series Combine with 15.2-m (50-ft) Hinged Draper

X Series Combine with 15.2-m (50-ft) Hinged DraperHarvest acres faster than ever before with a 15.2-m (50-ft) John Deere Hinged Draper built off the 700D and 700FD Drapers’ proven foundation.

- Harvest over 12.1 ha (30 acres) an hour of wheat and soybeans with one HDR50 and X9 1100 Combine – When in canola, you can expect to harvest 10.1 ha (25 acres) an hour.

- Harvest an additional 13.4 ha (33 acres) per day with a John Deere 15.2-m (50-ft) Hinged Draper – Go across the field fewer times by covering an additional 13.4 ha (33 acres) per day compared to similar 13.7-m (45-ft) models at the same ground speed.

Follow the ground to capture more crop

X Series Combine with 15.2-m (50-ft) Hinged Draper

X Series Combine with 15.2-m (50-ft) Hinged DraperJohn Deere HDR and HDF Drapers follow the ground by pivoting, gliding, and flexing over uneven fields to provide the best cut possible.

- Achieve the best of both worlds by adding a flexible cutterbar to a hinged draper, which already provides double the wing range of the MacDon® FD1 Draper – Hinged Drapers are available with a rigid knife on an HDR and a flexible knife on an HDF. The HDF Hinged Draper reduces missed crop when cutting on the ground in soybeans or lentils by 6 percent compared to MacDon and 2 percent compared to the HDR and RDF.*

- *NOTE: Theoretical internal John Deere study between a 45-m (13.7-ft) MacDon FD75, 640FD, HDR50, and HDF50 based on static machines by measuring the area between the knife and ground based on the average lowest pod.

- Capture more crop by adjusting to the ground – Industry-exclusive hydraulic suspension separates the header from the combine, allowing it to float over the field for a more consistent cut. As the header approaches extreme field terrain, Active Feeder house Position Control automatically adjusts the feeder house height to position , enabling more float range in challenging fields

- Harvest in difficult crop conditions – Capture downed crop with the push of a button on the CommandARM™ console to automatically raise the gauge wheels and extend your reel out and down. Harvest the most challenging lodged crop confidently with a 24 percent increase in reel torque (compared to the 700FD).

- Keep a clean cutterbar no matter the field or crop – A more consistent distance between the reel fingers and cutterbar (compared to the MacDon FD145) ensures the crop is cleanly swept across the cutterbar and evenly fed into the combine throughout the full wing range.

- Improve the consistency of stubble height by 25 percent compared to the MacDon FD1 – Achieve consistent stubble height behind the combine – an advantage for better seeding performance in no-till applications. Compared to the competition, operators no longer must leave the cab to set the cut height with John Deere height control gauge wheels. The draper automatically maintains the desired cut height while floating over the land.

MacDon is a trademark of MacDon Industries Ltd.

Harvest all your crops with confidence with the versatile, multi-crop John Deere HDX Draper Platform

The multi-crop HDX Draper Platform

The multi-crop HDX Draper Platform

A true multi-crop header is your insurance to handling your crops with one header. The HDX is the only header that can handle all crops and conditions without compromise from high-yielding, high-moisture, bushy oilseed rape to short and dry peas that need to be cut low to the ground.

The goals for a successful harvest are simple: harvest on time and put all the grain in the tank from all your crops. The John Deere HDX Draper is designed to take those goals to another level.

The HDX Draper combines the benefits of active feeding from draper belt technology with an extended table for harvesting tall or difficult bushy crops such as tillered oilseed rape. This results in increased combine performance with a header for all different crop conditions and types.

- Extended table design for improved feeding – The 1200-mm (47.2-in.) extended table provides producers who grow cereals crops as well as high-volume oilseed rape with unmatched crop material handling capabilities.

- Reduce header loss by 25 percent – John Deere Grain Saver Draper Belts trap grain before it can roll down the belts, past the cutterbar, and onto the ground (compared to standard draper belts) by using a patented and unique crosshair (+) design on the belts.

- Reduce loss in oilseed rape by up to 26 percent – Decrease header loss in high-volume oilseed rape with large fingered top augers (compared to non-fingered augers) that grab fluffy crops and hold them against the draper belts. Fingered top augers enable you to easily straight-cut oilseed rape.

- Capture more crop with the center section seal kit – This kit is required for oilseed rape to prevent seed from rolling off the sides of the center belt.

- Reduce shatter losses – Mechanically driven side knives reduce vibration that causes shatter loss, and a high reel lift range minimizes reel contact with tall oilseed rape.

- Crop changeover – When changing between crops, the mechanical side knives can be installed or un-installed in less than 5 minutes.

- Close reel-to-cutterbar relationship – Industry-leading close reel-to-cutterbar relationship sweeps short crops easily from the knife to the belt.

- On-ground cutting – Superior ground following capabilities with the hinged frame for on- and off-ground cutting ensure an even stubble height and less missed crop.

- Intuiative settings controlled from the cab – Quickly and easily change cut height, ground following settings, and belt speed adjustments from the cab as field and crop conditions change.

Harvest more grain in more crops with one header

Harvest more grain in more crops with one headerHarvest difficult crops with improved reel lift, range, and torque

Reel harvesting standing crop

Reel harvesting standing crop Reel harvesting downed crop

Reel harvesting downed cropOverview

On top of a tighter reel-to-cutterbar relationship, the reel also can reach out farther and lower with a 24 percent increase in reel torque compared to the 700FD HydraFlex™ Drapers. This draper makes quick work of downed and lodged crops.

Benefits

- Minimize reel threshing and header loss with increased reel height.

- Reduce missed grain in the field with increased reel reach that can go 100-mm (4-in.) deeper to the ground to help harvest lodged or downed crop.

Additional details

Reel positioned down

Reel positioned down Reel positioned up

Reel positioned upReel range measurements:

- Hinged Drapers have a 100-mm (4-in.) closer reel clearance and deeper ground reach than the 700FD.

- 30 percent increase in reel height maximum reach compared to the 700FD Series.

- Vertical range (distance off the cutterbar): 1000 mm (40 in.)

- Fore/aft range: 360 mm (14 in.)

- Fore of cutterbar: 265 mm (10.5 in.)

Reduce cutterbar loss with Grain Saver Draper Belts

Overview

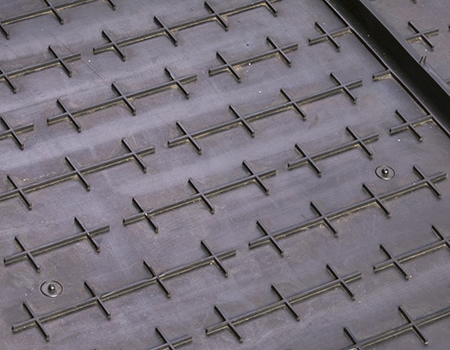

Reduce cutterbar loss by 25 percent with John Deere Grain Saver Draper Belts compared to standard draper belts. A special crosshair design on the belt helps trap free grain before it can roll past the cutterbar onto the ground. It is a very simple yet smart design that producers will appreciate in the field after seeing their elevator ticket.

Benefits

- Reduce canola cutterbar loss up to 25 percent with Grain Saver Draper Belts compared to traditional smooth draper belts.

- These side belts retain free grain that may have shelled out as the plant fell onto the draper or because of the reel contacting the crop.

Grain saver belt reduces loss

Grain saver belt reduces loss Grain saver belts reduces loss

Grain saver belts reduces loss Cleat design of the draper belt

Cleat design of the draper beltExtended draper belt on the HDX provides multi-crop performance

Extended draper belt for high performance in cereals and rapeseed

Extended draper belt for high performance in cereals and rapeseedOverview

The HDX Series Draper was designed to provide producers who grow cereal crops as well as high-volume rapeseed with a true high-performance multi-crop draper. It combines the benefits of the active feeding draper technology with the benefits of an extended cutterbar platform.

Benefits

- Consistent and uniform feeding in all crops and heads-first feeding of cereal crops leads to more consistent and uniform combine loading, resulting in superior threshing and reduced combine losses.

- Greater room on the platform enables harvest of high-volume sensitive crops that are susceptible to shatter loss due to hitting the backsheet or contact by the reel while conveying to the center feed section.

- Combined with the increased reel range and the fingered top auger, the HDX Series provides the ultimate solution for harvesting high-volume crops.

- In addition to the grain saver belt, it provides a perfect fit to reduce free grain losses.

Additional details

Deeper platform with 1200-mm (47.2-in.) draper belts

Deeper platform with 1200-mm (47.2-in.) draper belts- The HDX Series features a deeper platform with draper belts that measure 1200 mm (47.2 in.) compared to the HDR Series that measures 1000 mm (39.4 in.).

Improve performance with John Deere designed side knives and storage bracket

Overview

Harvesting in the field

Harvesting in the fieldThe toolless, quick-attach side knives enable operators to convert from cereal dividers to side knives in less than 5 minutes. This is important for operators during times of the year where they are switching between crops throughout the harvest day.

Benefits

- Prevent stalling when engaging in tough crop with a vertical knife, driven mechanically from the cutterbar knife drive system.

- In some varieties of spring-seeded canola, side knives provide crop separation at end dividers and prevent crop from riding up the divider and creating shatter loss, while also reducing buildup of material on the top of the divider.

Side knife

Side knife Dual side knives installed on draper

Dual side knives installed on draperAdditional details

- These side knives are designed and manufactured by John Deere rather than the Zurn side knife options for the 700FD Series. The side knives can be removed and swapped to another Hinged Draper model if the draper was ordered with short poly divider side knife ready option.

- There are no special combine requirements to use these side knives. They are 1467-mm (57.75-in.) tall.

- The side knife is mechanically driven off the gearbox located inside the end divider when ordered with the side knife ready end divider option.

Side knife storage bracket

Side knife storage bracketConsistent and smooth terrain following with the center frame suspension system

Overview

Experience consistent and smooth terrain following performance with a draper integrated attachment and center frame that enables passive terrain following, resulting in less missed crop and a more consistent stubble height.

Benefits

- Reduce the chance of the attachment frame ever reaching maximum range of float while extending float range by having the draper hydraulic suspension and Active Feederhouse Position Control work together to achieve desired cut height.

- The attachment frame separates combine movement from the draper mainframe in the field. This allows the combine and draper to move independently.

- Hydraulic versus mechanical suspension systems:

- Hydraulic float suspension provides near constant force through the travel range of the attachment frame, while mechanical suspension systems (MacDon® headers use springs) provide incremental force through travel range.

- Float pressure can be changed from the cab for changing ground conditions.

- Achieve increased float range while achieving consistent float pressure.

- Reduce draper bounce when traveling over ridges or through waterways and sprayer ruts.

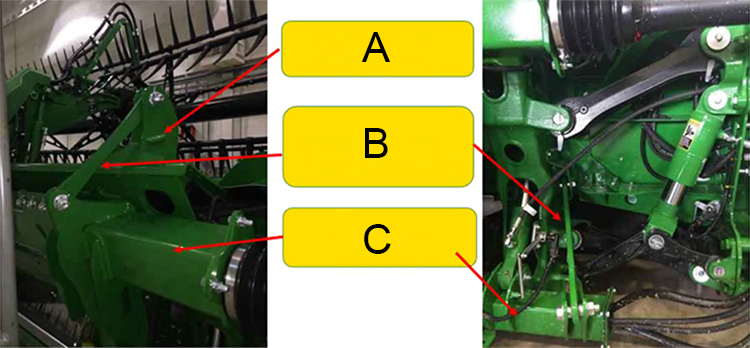

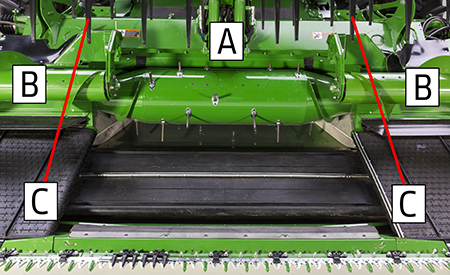

Center frame suspension system: center frame (A), center frame linkages (B), attachment frame (C)

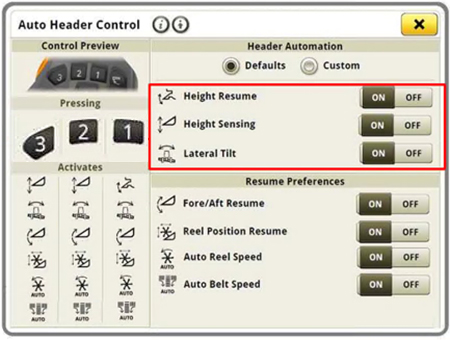

Center frame suspension system: center frame (A), center frame linkages (B), attachment frame (C) Automated height sensing

Automated height sensingNOTE: HDR and HDF models always require auto header height sensing to be on, but for the best performance, all automated features should be on.

Additional details

- There are four links that control attachment frame to center frame motion. The wing links control the wing to center frame motion. The center frame links and the wing links move independently from one another. These four suspension systems function independently and are not dependent on each other.

- The attachment frame is where the combine feederhouse attaches to the draper. The attachment frame moves with the combine face plate while the header continues to keep the desired relationship to the ground.

- Although the center frame attaches to the attachment frame, the center frame can travel 13.7 cm (5.4 in.) independently (6.86 cm [2.7 in.] up and 6.86 cm [2.7 in.] down) from the attachment frame. The wing and center frame systems are passive. This means that the combine does not actively move them or control them. They follow the contours in the field.

- Being independent from the attachment frame, there is also +/- 4.1 degrees of lateral movement allowed (8.2 degrees total range).

MacDon is a trademark of MacDon Industries Ltd.

Harvest more effectively with a hinged frame and improved reel-to-cutterbar relationship

Overview

Reduce passes through washouts, hills, bottoms, and terraces in the field with a hinged frame draper, which allows operators to take and most importantly cut more full-width passes in the fields.

Hinged frame on HDR and HDF Drapers

Hinged frame on HDR and HDF Drapers Hinged frame on HDR and HDF Drapers

Hinged frame on HDR and HDF DrapersBenefits

- Minimize yield loss in challenging fields with a hinged frame draper that provides double the wing range compared to the MacDon® FD145 Draper.

- In fields with varying terrain, a tighter and more consistent distance between reel fingers and the cutterbar compared to the MacDon FD145 ensures crop is swept into the center feed section by the reel through the full wing range.

- In off-ground cutting, the draper delivers a more consistent cut height across the full width of the cutterbar in a wide range of terrain profiles, resulting in more consistent stubble height.

- Capture more crop during on-ground cutting with better ground-following and less bulldozing, even in rolling or terraced fields.

- Harvest fields in one block rather than individual terrace channels by running the hinged frame draper back and forth over terraces in nearly any direction. This process saves turn-around time and reduces loss when the machine cleans out each time when turning around.

Additional details

Draper center frame (A), wings (B), and hinged points (C)

Draper center frame (A), wings (B), and hinged points (C) Reel is closer to the cutterbar

Reel is closer to the cutterbar- Draper frame wings attach to the draper center frame to provide +/- 5 degrees of wing range travel up and down independent of attachment frame position. This results in different maximum heights at the outer float arm (depending on header width).

- The HD45R provides 51.6 cm (20.3 in.) of wing range at the divider point, 200 percent more than the MacDon FD145 with 25.4 cm (10 in.) of wing range.

- Like the attachment frame, hydraulic wing float suspension provides constant force through the wings travel, while mechanical suspension systems (MacDon FD145 uses springs) provide incremental force through travel range.

- Wing pivot points are projected toward the center of the header rather than a pivot point on the side of the center section frame like MacDon. Projecting the pivot to the center of the header delivers a more constant wing float ground pressure, thereby reducing tendency to push or bulldoze as the wing moves to the top and bottom of the wing range.

| Draper model | John Deere HD Series (+/- 5 degrees) | MacDon (+/- 2.5 degrees) | CLAAS® CONVIO (+/- 0 degrees) |

| Valley or washout |  |  |  |

| Crest or ridge |

Reel cutterbar flat

Reel cutterbar flat Reel cutterbar up

Reel cutterbar up Reel cutterbar down

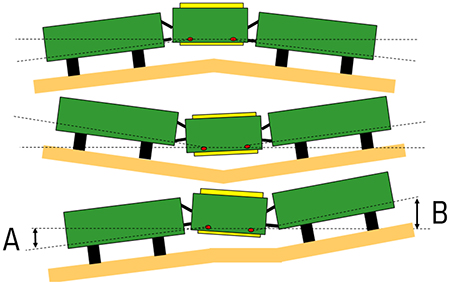

Reel cutterbar downWing frame passive motion

10 degrees of wing motion (A is -5 degrees of wing motion and B is +5 degrees of wing motion)

10 degrees of wing motion (A is -5 degrees of wing motion and B is +5 degrees of wing motion)All the frames (left wing, center, and right wing) being independent from one another allow for a wide range of motion for the header to maneuver. There are 10 degrees of travel between the wing frames and the center frame (5 degrees up and 5 degrees down).

MacDon is a trademark of MacDon Industries Ltd. CLAAS is a trademark of CLAAS KGaA mbH.

Match ground conditions with easy draper adjustment from the cab

Overview

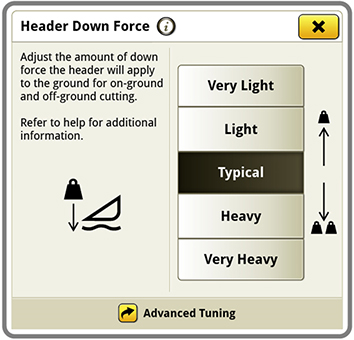

Ground conditions change day to day, field to field, and hour to hour. Ensure ground conditions do not make operators come to a halt with the ability to quickly adjust header down force. Five ground condition settings let operators adjust the draper to follow fields better without leaving the cab.

Benefits

- Save time during the day with down force adjustments completed from the cab compared to competitive models that use out-of-cab, by-hand adjustments.

- Changes can be made on the fly without stopping, meaning the operator does not have to leave the cab, remove panels, or find and use tools to make attachment frame float pressure and wing balance adjustments.

- Maintain desired down force across the entire header with wing positions that are adjusted through hydraulic cylinders and linkages based on terrain and operator settings.

Additional details

- When harvesting on the ground, the cutterbar is the only component of the draper that is needed to contact the ground to drive great cutting performance.

- The pressure in the system is fixed; the large-volume accumulators and orientation of the cylinders work together to keep the achieved header down force constant throughout the entire wing/attachment frame motion.

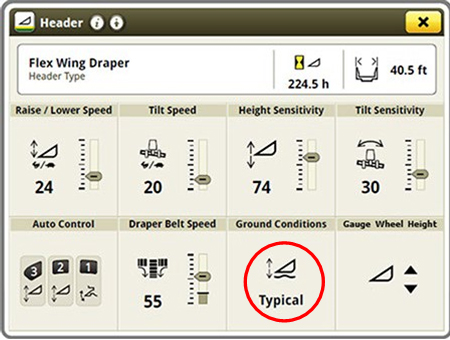

Select the header down force button to change the setting

Select the header down force button to change the setting Header down force settings on display

Header down force settings on displayAll attachment frame and draper frame wings suspension tuning is performed within the header application on the 4600 CommandCenter™ Display.

Automatic header height sensing mode needs to be active in order to make an adjustment to header down force. There is not a pressure reading displayed to the operator as there use to be with HydraFlex™ technology. The operator simply selects the current ground conditions for header operation.

These are factory settings for suspension pressures for five different conditions:

- Very light – extremely hard ground conditions

- Light – hard ground conditions

- Typical – normal ground conditions (default)

- Heavy – wet ground conditions

- Very heavy – very wet ground conditions

The heavier the setting, the more rigid the suspension.

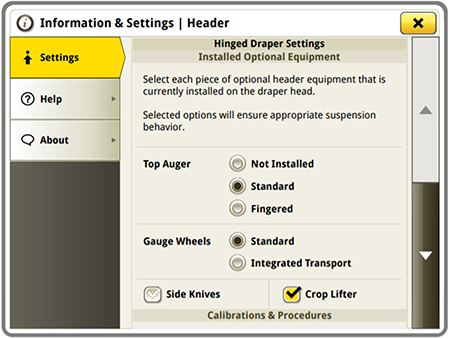

Configure optional equipment in the Installed Optional Equipment screen

Configure optional equipment in the Installed Optional Equipment screen- The installed optional equipment section is a specific feature for Hinged Drapers which allows the dealer or producer to configure the draper after installing or removing optional equipment such as top augers, gauge wheel type, side knives, and crop lifters while not compromising ground following performance.

- From the factory, the optional equipment is saved based upon the header configuration ordered.