- 21.3 m (70 ft.) working width at 25.4 cm or 30.5 cm (10-in. or 12-in.) spacing

- Dual Knife Openers

- Relative Flow™ blockage monitoring

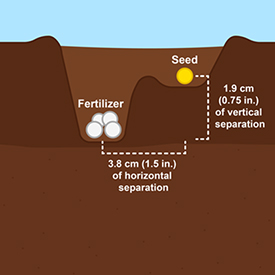

- Uniform seed and fertiliser placement with a consistent 1.9 cm (0.75-in.) vertical and 3.8 cm (1.5-in.) horizontal spread.

Features

The Total Seeding Solution – Experience the John Deere Advantage

John Deere has the seeding solutions that go above expectations with a complete line of everything needed in small grains. Offering a variety of openers for your chosen practice in a variety of configurations and sizes. All with integrated technology throughout the seeding train allows for effortless setup and seamless documentation.

Total seeding solution

Total seeding solution Setting up a John Deere seeding train is quick and easy with the plug and play technology. All data and technology operate through the Gen 4 display and ultimately up to John Deere Operation Center™ that can be viewed from anywhere at any time. Not only does the complete John Deere seeding solution all operate through one display but it eliminates the difficulty and time-consuming tasks of setting up extra displays and harnesses.

John Deere tractor paired with John Deere tool and cart

John Deere tractor paired with John Deere tool and cartWith a complete John Deere seeding solution, there are multiple different onboard and offboard technologies shown below that improve the overall seeding production step. Many of these technologies are exclusive to John Deere. Each of these technologies bring different customer value that overall lead to the ultimate John Deere seeding solution!

On the go, quick adjust downforce with TruSet™ from the cab

- Adjust downforce pressure to improve uniform emergence

- Set presets to quickly adjust from field to field

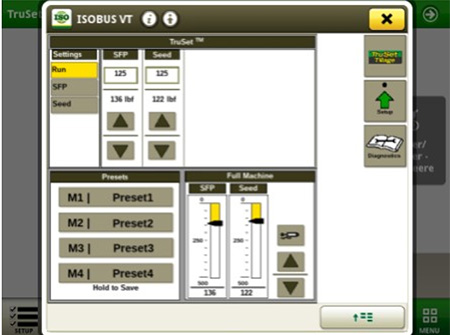

TruSet downforce display

TruSet downforce displayMonitor blockage row by row from the cab with RelativeFlow™

- Seed with confidence while monitoring each row

- Detect blockage early and know exactly where it is

RelativeFlow blockage sensors

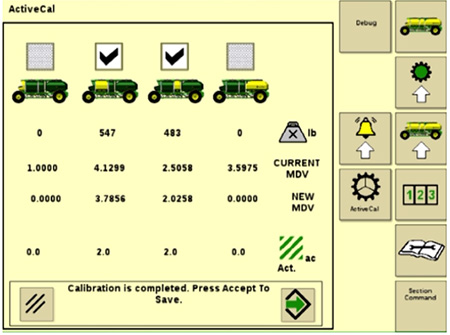

RelativeFlow blockage sensorsActiveCal™ display

- Calibrate the meters from the cab utilizing the tank scales

- Improved confidence the correct seeding rates are being met

ActiveCal display

ActiveCal displaySectionCommand™ controls seed and fertilizer output

- Controls seed and fertilizer output by closing and opening gates on the meters

- Minimize skips and overlaps leading to reduced inputs

Example of seeded field with SectionCommand

Example of seeded field with SectionCommandAutoTrac™ Implement Guidance and AutoTrac Turn Automation

- Make every operator an experienced operator

- Precisely placed implements for more accurate seeding, less operator fatigue, and more productivity

- Hands-free turns within field headlands (with AutoTrac Turn Automation enabled)

AutoTrac Turn Automation display

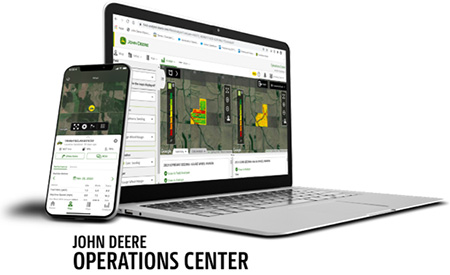

AutoTrac Turn Automation displayJohn Deere Operation Center™

- Setup and manage your farm operations: equipment, team, fields, and crop inputs

- Plan work in advance to increase job quality and efficiency with Work Planner

- Map based prescriptions can be used with variable rates

- Analyze this season’s results to improve next season’s crops

John Deere Operation Center web and mobile

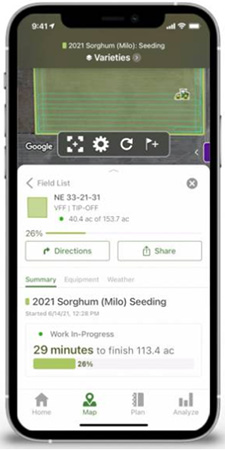

John Deere Operation Center web and mobileOperation Center Mobile

- View your data on the go; remotely monitor job quality, productivity, machine performance, and quickly make informed decisions

- Manage and monitor from anywhere at any time with near real-time field and machine updates

Operation Center Mobile

Operation Center MobileConnected Support

- Expert Alerts proactively notifies your dealer of any issues

- Remote display access allows for easy on the go support

Connected Support

Connected SupportFor more information regarding Large Tractors and Precision Ag, view the following landing pages

Consistent performance across all soil conditions with the P600 opener

P600 opener

P600 openerThe P600 Precision Air Hoe Drill opener provides exceptional agronomic performance across all soil and field conditions. Its double knife design places nutrients right where your crop needs it without compromising safety. The fixed relationship between seed and fertilizer minimizes row-to-row variability, allowing for an even crop at emergence and at harvest. With its maintenance-free pivot point, extended wear knives, and quick-change depth settings, it is also easy to use and economical to maintain.

Integrated insights from the complete John Deere seeding solution

9RX Tractor with a C-Series Cart and P600 Precision Air Hoe Drill

9RX Tractor with a C-Series Cart and P600 Precision Air Hoe DrillWith John Deere 9R Tractors, C-Series Carts, P600 Precision Air Hoe Drills, and John Deere Operations Center™ application, you have all the insights you need to maximize profitability and understand your seeding operation. All of this comes in an easy-to-use format combined with wireless data transfer, so you spend more time working on what matters.

Increased productivity from larger width offerings

Larger working widths available on the P600

Larger working widths available on the P600With both 24.4-m and 27.4-m (80-ft and 90-ft) working widths available, the P600 allows you to be more productive than ever before. The P690 is 9 percent more productive than the previous largest offering from John Deere, the P576. In the real world 9 percent means it takes five fewer passes to seed a 64.75-ha (160-acre) field than the P576.

Technology that pays

RelativeFlow™ on the P600

RelativeFlow™ on the P600 TruSet™ Home Page on the P600

TruSet™ Home Page on the P600The John Deere seeding solution gives you the tools to maximize profitability in your operation. Features like RelativeFlow sensors and TruSet provide peace of mind that you did the best job possible when seeding. John Deere Operations Center™ application gives you the full picture of your operation, providing you the power to make informed choices.

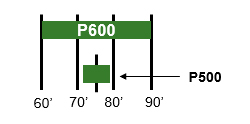

P500 vs P600? Which one is the right Precision Hoe Drill for you?

When considering a new precision hoe drill from John Deere, it is important to understand the differences between the P500 and the P600. There are key differences in the two openers that are outlined below. Understanding the differences will help the customer have the best performance for their exact situation.

| P500 | P600 |

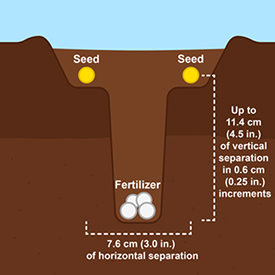

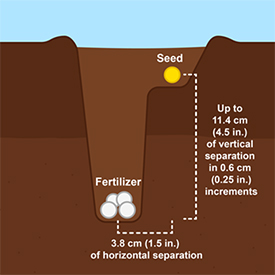

Opener type | Paired row – side band Single row – side band | Dual knife – side band |

Seed to fertilizer horizontal separation | 3.8 cm (1.5 in.) consistent separation | 3.8 cm (1.5 in.) consistent separation |

Seed to fertilizer vertical separation | Adjustable up to 11.4 cm (4.5 in.) | 1.9 cm (0.75 in.) consistent separation |

HP per opener required | 6 HP | 5 HP |

Available row spacing | 9 in. paired rows and 12 in. single row | 10 in. and 12 in. |

Working widths available | 40 ft and 56 ft | 60 ft, 70 ft, 80 ft, and 90 ft |

RelativeFlow™ available | Yes | Yes |

TruSet™ available | No | Yes |

Agronomic value |

|

|

P500 paired row separation

P500 paired row separation P500 single row separation

P500 single row separation P600 separation

P600 separation