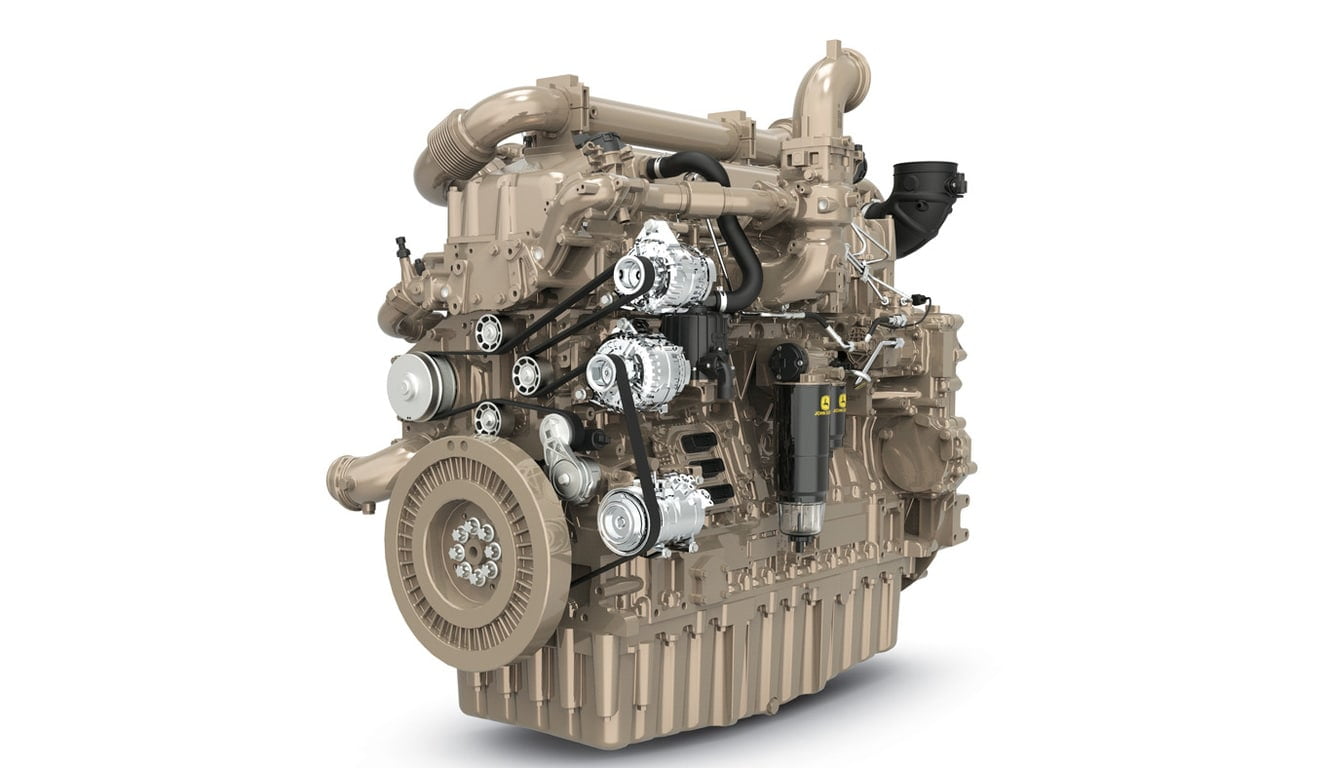

JD18X (6180CI510)

Industrial Diesel Engine

Nothing Runs Like a Deere™

- 522-677 kW (700-908 hp)

- Continuous, Heavy Duty, Intermittent

X

Select Your Closest Emmetts Branch and Ask About This Machine Today!

Features

Get details on John Deere JD18X industrial diesel engines for OEM equipment, including features, specs, and integrated support

Expand All

Stage V.

- John Deere has billions of hours of field experience with off-highway diesel engine technologies and launched many of its engines ahead of EPA and EU deadlines, and is ready to meet Stage V emissions regulations. Our engineers continue to employ a global network of technical resources and the latest technology to lower emissions while improving performance and fluid efficiency.

Series turbocharger

- Air is first drawn into the low-pressure turbocharger and compressed to a higher pressure. The compressed air is then drawn into the high-pressure turbocharger, where the air is further compressed. The high-pressure air is then routed through a charge air cooler and into the engine's intake manifold. By splitting the work between two turbochargers, both can operate at peak efficiency and at slower rotating speeds — lowering stress on turbocharger components and improving reliability. Series turbocharging delivers more boost pressure than single turbocharger configurations, which results in higher power density, improved low-speed torque, and improved high-altitude operation.

Cooled exhaust gas recirculation (EGR)

- EGR cools and mixes measured amounts of cooled exhaust gas with incoming fresh air to lower peak combustion temperatures, thereby reducing Nox.

High-pressure common-rail (HPCR)

- The HPCR fuel system provides variable common-rail pressure and high injection pressures. It also controls fuel injection timing and provides precise control for the start, duration, and end of injection.

Air-to-air aftercooled

- This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

4-valve cylinder head

- The 4-valve cylinder head provides excellent airflow resulting in excellent low-speed torque and transient response.

Rear gear train

- The engine features a rear gear train, which produces excellent direct power and options up to two rear aux drives for a total of 902 Nm (665 lb-ft) max torque providing quiet operation.

John Deere electronic engine controls

- Premium software integrates with equipment or vehicles to reduce engineering and installation costs.

- The John Deere controls offer better diagnostic capabilities, enabling future prognostics, and the ability to target the source of engine performance issues.

Big-engine durability

- The bedplate design provides structural benefits for extreme durability and is built for 20,000 hours of operation with the ability to be re-built two times.

- Replaceable (wet) cylinder liners

- Full flow engine-mounted oil cooler

- Up to 500-hour oil change

Serviceability and repairability

- Designed with the ease of service and repair in mind, with Hydraulic Lash Adjustment (HLAs), which offers a maintenance free valvetrain, eliminating the need to reset lash.

Additional features

- Engine-mounted fuel filter

- Low-pressure fuel system with electrical transfer pump and "auto-prime" feature

- Optional rear PTO

Specifications

Expand All

Emissions Certifications

- EPA Final Tier 4

- EU Stage V

General Engine Data

- Model

- 6180CI510

- Number of cylinders

- 6

- Displacement-- L (cu in)

- 18.0 (1098)

- Bore and Stroke-- mm (in)

- 148 x 174 (5.8 x 6.8)

- Engine Type

- In-line, 4-cycle

- Aspiration

- Turbocharged and air-to-air aftercooled

- Length - mm (in)

- 1750 (69)*

*Dimensions may vary based on options selected.

- Width-- mm (in)

- 920 (36)

- Height-- mm (in)

- 1507 (59)

- Weight, dry - kg (lb)

- 2119 (4672)*

*With oil, no coolant (includes engine, flywheel housing, flywheel & electronics)

Performance Data Range

- Rated power

- 522-677 kW (700-908 hp) @ 1900 rpm

- Peak power

- 560-677 kW (751-908 hp) @ 1700 rpm

- Application rating

- Continuous, Heavy Duty, Intermittent

- Peak torque

- 4250 Nm (3135 lb-ft) @ 1400 rpm

Copyright 2024 Emmett Motors.