- Confidently unload crops on the go through reliable and automated machine-to-machine synchronisation during a harvest operation.

- Reduce operator-to-operator interactions by allowing the harvester operator to control the follower machine's position during the unloading process.

- Decrease the likelihood of machine collisions, especially in dark or dusty field conditions.

- Increase harvest efficiency by sharing machine locations, coverage maps, and guidance lines between up to six machines working in the same field using In-Field Data Sharing, in conjunction with Machine Sync.

Features

Automatically coordinate grain and commodity cart speed and position with the harvester

S-Series Combine unloading on the go

S-Series Combine unloading on the go X Series Combine unloading on the go

X Series Combine unloading on the goHarvest is hectic as you focus on getting all the crop from the field to the bin within a tight harvest window. Using Machine Sync, you can focus more on grain harvest and grain quality and worry less about keeping the grain cart under the spout when unloading on the go. Gen 4 Machine Sync provides a solution to harvest stress by creating a wireless network between the tractor and combine to enable on-the-go unloading through synchronization of tractor speed and direction of travel with the combine.

In traditional grain cart operations, operators are focused on being in the right place at the right time. Previously, successfully unloading grain into a grain cart while continuing to harvest crop was complicated due to:

- Communication between operators

- Matching speeds between combine and grain cart

- Awareness of upcoming waterways and field contour and agreement how to navigate

- Awareness of equipment size and position

Gen 4 Machine Sync simplifies harvest for even the most experienced operators. It allows focus on harvest while reducing the tasks created by on-the-go unloading. This results in operators who are more relaxed, productive, and alert during harvest.

Machine Sync guides an approaching grain cart tractor to a predetermined “Home” position for unloading. This is a unique home point for that specific grain cart tractor/combine. Individual home points allow combines, tractors, and grain carts to have different configurations (duals, cart sizes, and unloading auger lengths).

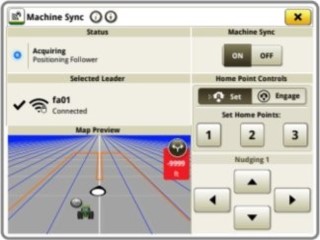

Speed and direction synchronization can begin once the tractor and grain cart enter the area to the left of the combine. This area is known as the operational zone and is displayed in the image above as the orange box. Once the tractor operator engages Machine Sync, the tractor travels towards the home point and the two machines are actively tracking. The control of tractor speed and direction of travel is then given to the combine operator.

As the combine continues to harvest, the combine operator can engage the unloading auger, filling the grain cart. While synchronized, the grain cart tractor mimics the movements of the combine. The combine and tractor/grain cart continue to travel in a synchronized fashion until the tractor operator disengages Machine Sync. The tractor operator can do this by simply taking control of the steering wheel or manually changing speed.

While the combine and tractor/grain cart are tracking and unloading, the combine operator can make incremental speed and direction changes to the tractor in order to evenly fill the cart. Nudge buttons on the Gen 4 Display allow the tractor and grain cart to be nudged forward, backward, or side to side. To ensure the full capacity of the grain cart is being utilized, swing the unloading auger for final fill.

Reduce the chance of missing the wagon or cart by automating direct-load harvester operations

Unloading a self-propelled forage harvester (SPFH)

Unloading a self-propelled forage harvester (SPFH) Unloading a pull-type potato harvester

Unloading a pull-type potato harvesterGen 4 Machine Sync can provide harvest automation to a variety of crops ranging from silage and haylage to potatoes and onions to large and small grains. Machine Sync provides position and speed control for carts or buggies pulled by a John Deere tractor. This means you can run John Deere SPFH, John Deere combines, and John Deere tractors with pull-type harvesters and experience the benefits of Machine Sync.

SPFHs and pull-type harvesters offers an optional U-shaped unloading zone. This allows you to benefit from Machine Sync automation while unloading on the left, right, or rear of the machine. You can also save up to three home points when using the U-shaped unloading zone, cutting down on the time spent changing or saving your cart location based on the side of the machine you are unloading on.

Setting home points in the machine sync page

Setting home points in the machine sync page Operating in the U-shaped unloading zone

Operating in the U-shaped unloading zoneIncrease efficiency with harvest logistics

Enable faster decisions for a more efficient harvest by seeing the location of all machines in a field and combine grain tank levels. Knowing combine grain tank fill levels and location helps grain cart operators decide which combine to unload first. Minimizing wait time for a grain cart reduces the amount of idle time each combine accumulates during the season. Combines, grain carts, and semis can plan and perform at maximum efficiency with Machine Sync.

Operators will see the following information for each machine in a network with an active JDLink™ Connect subscription and In-Field Data Sharing functionality:

- Combine location and direction of travel

- Grain cart location

- Combine grain tank fill level

- Combine unloading auger status

Viewing shared coverage maps between all machines operating in the field allows grain cart operators to see what headlands have been harvested and if there are any areas that have been broken through that would allow for a shorter path to the combine.

Make harvest easier for any operator

With shrinking labor within the agriculture industry, finding highly skilled individuals to operator equipment during harvest can be challenging. Machine Sync provides an automated harvest solution that provides less-experienced operators, with the technology to be highly productive and efficient.

Reduce compaction with controlled traffic farming practices

Reduce compaction with controlled traffic farming by sharing guidance lines between the leader and follower machines. This means you always know where the follower is and will be going within the field. Controlled traffic farming works by providing guidance lines that both the leader and follower can use throughout the field. You can also use AutoTrac™ guidance in and out of the Machine Sync operation zone.