- Activation lets you control machine function and precision ag applications from one display in the cab.

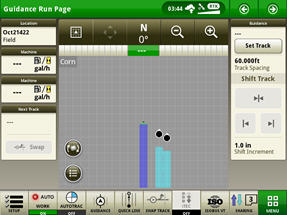

- Redesigned, easy-to-use interface features shortcut bar for entering and reviewing information quickly.

- With JDLink Connect, data is automatically sent to John Deere Operations Center.

Features

Unlock the precision execution capabilities of 4600 CommandCenter™ Display with the CommandCenter Premium activation

Producers ready to take the next step toward precise job execution in their precision ag journey are ready for the CommandCenter Premium Activation. The bundle includes a set of John Deere precision ag applications to help them do more work with more precision and to share information wirelessly between machines and with the John Deere Operations Center.

The CommandCenter Premium activation gathers three precision ag applications into a single orderable product for the 4600 CommandCenter Display with options to upgrade from other activation levels. This approach delivers more total customer value in a way that allows producers to use the applications they want throughout the crop production cycle without the worry and expense of licensing individual precision ag applications. It all begins with better planter control with Section Control and more efficient nutrient and crop protection application with AutoTrac™ RowSense™. Finish the crop season at harvest by being able to easily follow standing crop rows with RowSense in the combine all while sharing information between machines working in the same field with In-Field Data Sharing.

With the CommandCenter Premium 3.0 Activation, operators have access to the following applications:

- Section Control

- AutoTrac RowSense

- In-Field Data Sharing

CommandCenter Premium 3.0 Activation is a non-transferrable display activation compatible with any John Deere machine equipped with a 4600 CommandCenter Display and v2 server. Functionality is dependent on machine configuration and may require additional hardware. Data created with a Gen 4 display is only compatible with John Deere Operations Center and can be transferred either wirelessly or via a USB drive with 4- to 32-GB capacity.

Reduce skips and overlaps with Section Control

John Deere Section Control switches boom sections on or off, reducing overlap and improving product placement.

Key features of John Deere Section Control include:

- Automatic control of sprayer sections when passing across:

- Previous coverage

- Exterior and interior boundaries

- Established headlands (buffer zones)

- Improve efficiency by reducing overlap, skips, input costs, and operator stress

- Easier setup with distance-based tuning

John Deere Section Control is available as part of the CommandCenter™ Premium application and requires a StarFire™ position receiver.

Reduce operator stress while following crop rows with AutoTrac™ RowSense™ system

AutoTrac RowSense system

A relaxed operator using AutoTrac RowSense software in an R4038

A relaxed operator using AutoTrac RowSense software in an R4038 Combine with RowSense sensor

Combine with RowSense sensor Hagie™ STS14 with RowSense sensor

Hagie™ STS14 with RowSense sensorPost-emergence operations such as spraying fungicide in July or harvesting corn in October can be stressful for operators. On top of steering the machine, an operator is required to monitor several other areas such as spray rates, ground terrain, grain or forage quality, or managing tender trucks and grain carts. Operating at night, in windy conditions, or while harvesting lodged corn can add even more stress for the operator.

Using feelers that engage the corp rows, AutoTrac RowSense has revolutionized the ability to use AutoTrac for post-emergence applications in later-season corn.

A study using advanced, eye-tracking glasses determined where an operator’s attention is focused while operating a sprayer through tall, standing corn. Without AutoTrac RowSense or Vision, the operator spent about 82.5 percent of the time looking forward. When AutoTrac RowSense or Vision was utilized, the same operators only spent 70 percent of the time looking forward and more time watching sprayer booms and monitoring machine performance on the vehicle display. AutoTrac RowSense focuses on steering so the operator can focus on other value-added tasks.

Hagie is a trademark of Hagie Manufacturing Company, LLC and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

Use equipment and people even better with In-Field Data Sharing

Using Gen 4 In-Field Data Sharing, up to six tractors, sprayers, nutrient applicators, or combines can share as applied maps and guidance lines to reduce overlap, improve product placement, and monitor job quality in other machines. Equipment can work together at the same time or use maps created earlier by another machine to increase efficiency.

Three machines sharing coverage

Three machines sharing coverage Sharing as-applied maps

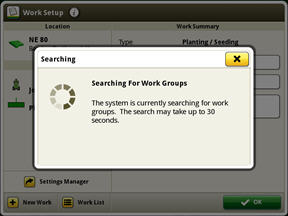

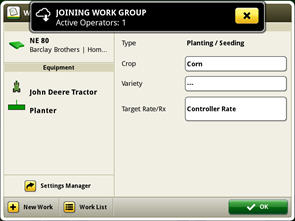

Sharing as-applied mapsUsing a streamlined setup process, In-Field Data Sharing matches maps and guidance lines together based on the information selected in the Work Setup screen, the same information is needed to document an operation. Setup items can be sent to the display from Operations Center for selection to make setup even easier.

Searching for other work groups

Searching for other work groups Joining a work group

Joining a work groupThe information needed depends on the operation:

- Planting and seeding: Client, Farm, Field, and Crop

- Product application: Client, Farm, Field, and Product or Tank Mix

- Harvest: Client, Farm, Field, and Crop