- 74 kW (100 hp) rated power (ECE-R120)

- 88 kW (120 hp) rated power (ECE-R120) with IPM

- 4.5 l engine with 4 cylinders

- 5.7 t and 2,400 m wheelbase

Features

Cab tractors

6MC - 6RC Series Cab Tractor

6MC - 6RC Series Cab TractorThe 6MC and 6RC Series Cab Tractors provide room and great visibility, making row-crop and loader work easier while protecting the operator from environmental discomfort. These cab tractors combine form and function into an eye-pleasing combination with easy, uncluttered access to all tractors and implement controls.

The cab provides a comfortable working environment for those long days in all conditions with a low in-cab noise level. All-around visibility of 320 degrees from within the cab ensures accurate tractor placement, implement hookup, and optimum tractor performance.

Key features

Integrated Roll-Gard™ structure

Power outlet socket three pole

ToolboxMechanical front-wheel drive (MFWD) front axle - Triple-Link Suspension (TLS™)

TLS suspended front axle

TLS - front axle suspension

TLS - front axle suspension

TLS provides higher operator comfort by reducing fatigue and increases productivity.

It is optional and available for all 6RC Series Tractors with the following features:

- Self-leveling system with +/- 50-mm suspension travel under all axle load conditions.

- Permanent engagement of axle suspension with automatic adjustment of the sensitivity and suspension rate for the axle load (from a heavy rear-mounted implement to heavy front loader work)

- Optimized draft performance with its long draft member, by synchronizing with the hitch-sensing system to compensate power hop effect under heavy pull conditions.

- Up to seven percent more power to the ground

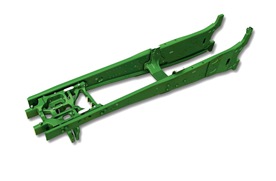

Full-frame design

Full-frame design

Full-frame design

6MC and 6RC Tractors are based on one frame size and wheelbase:

| Models | |

| 6090MC 6100MC 6110MC 6090RC 6100RC 6110RC | 2400 mm (9.4 in.) |

Strong steel frame has been a John Deere industry exclusive since 1992:

- Unique solution achieves higher payloads without increasing tractor weight

- Bridge-type frame provides superior structural strength and allows compact modular construction of transmission units

- Full frame carries the load while the powertrain transmits engine power to the final drive

- All components have a dedicated function and are designed without compromise

- Larger implements and heavier loads can be accommodated, resulting in higher levels of productivity

Improved serviceability

- Operators have less downtime and more uptime with quicker turnaround for service

- Complete modular component replacement is allowed without splitting the tractor in half

- Frame mounting allows easier component servicing without disturbing other systems

- The cab tilts so the tractor does not have to be split to access key components

Common transmission features

John Deere transmissions combine power-saving technology with well-proven design features to ensure:

- Reliability

- High efficiency

- Low noise

- Convenient operation

- Low service costs

For the 6MC – 6RC Series Tractors, the following basic transmissions are available:

| Transmission | Speed | 6MC | 6RC |

| PowrQuad™ Plus transmission | 30 km/h (18.6 mph) | 16/16 | Not applicable |

| PowrQuad Plus | 38 km/h (23.6 mph) | 16/16 | 16/16 |

| PowrQuad Plus | 40 km/h (24.9 mph) | 24/24 | 24/24 |

| AutoQuad™ Plus transmission | 40 km/h (24.9 mph) | Not applicable | 24/24 |

| AutoQuad Plus Eco | 40 km/h (24.9 mph) | Not applicable | 24/24 |

PowrQuad Plus transmission

PowrQuad Plus transmission

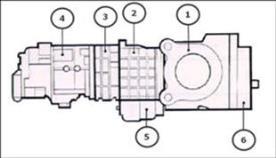

Modular concept

The full frame is designed to withstand heavy load and twisting applications, which allows the transmission and engine to be modular designed instead of being an integral part of the frame.

Since the transmission is not used as a structural member, there is greater flexibility in manufacturing processes for integrating options such as a creeper or mechanical front-wheel drive (MFWD).

Modular concept

Modular concept

- Differential housing

- Range module

- Option module (creeper)

- PowrQuad module (or PowrReverser and PermaClutch™ 2 clutch)

- MFWD - clutch module

- Power take-off (PTO) module

Three large clutch disks provide optimum clutch modulation for smooth operation, and the disks are oil-cooled for a lifetime of service. The PermaClutch 2 is especially suited to tough tractor applications, such as continuous front loader operations or other applications involving a large number of shuttle shifts.

Helical cut gears

The helical cut gears provide large-tooth contact for greater torque-transmitting capability and quieter operation.

Pressure lubrication

The pressurized lubrication system delivers cooled and filtered oil under all conditions. A warning light alerts the operator if oil pressure drops, preventing damage to the transmission.

Console shifting

All gear shift levers are conveniently located on the right-hand console. Easy-to-use shift pattern allows precise shifting without confusion.

Pressure compensated system (PC) – 65 L/min (17.2 gpm) and 80 L/min (21.1 gpm)

6MC Series Tractors feature a John Deere-designed, open-center, constant-flow pressure compensated (PC) hydraulic system with variable pressure up to full pressure of 200 bar (2900 psi).

Base equipment is a 65 L/min (17.2 gpm) gear pump for all 6MC models, optional a 80 L/min (21.1 gpm) gear pump for a higher flow is available.

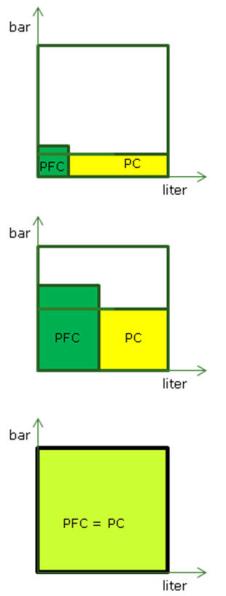

Differences between PC and PFC system

There are two different hydraulic systems available (PFC and PC).

The PC system offers a gear–type pump and is based on a continuous oil flow. The flow is always maximum, regardless of the need of the tractor or the implement. The pressure can vary depending on the settings of pressure regulating valves, but the maximum flow is generated by the gear-type pump, which has a direct influence on the engine efficiency.

The pressure is variable because of using pressure regulating valves, which effect a loss of power because

the pump is always in action and has to be driven by the motor. So, the pressure is not very high, and a big volume of hydraulic oil always circulates in the system.

The PFC system has a consumption–based hydraulic pump, which is mostly a piston pump. When no

hydraulic consumers are needed, the pump works in a reduced stand-by flow. If the tractor or its implement needs more hydraulic power, the pump starts to increase flow or pressure. The oil flow and oil pressure depend on the demand, and thanks to that, the pump is always in the most efficient condition. This system has a positive influence on the whole efficiency of the tractor because the hydraulic power is only provided when it is needed.

Legend of the diagrams:

- No hydraulic users

- Mid hydraulic demand

- Maximum hydraulic demand

Pressure- and flow-compensated system (PFC), 80 L/min (21.1 gpm) and 114 L/min (30.1 gpm)

6RC Series Tractors offer a closed-center, pressure-and-flow-compensated (PFC) hydraulic system with 80 L/min (21 gpm) of flow to the remotes up to 200 bar (2900 psi) of variable working pressure as base equipment. If a higher flow is required, a bigger pump with 114 L/min (30.1 gpm) is available.

The hydraulic system is load sensing, which means a valve on the pump immediately initiates pump flow when required. When flow is no longer required, the pump returns to low-pressure, no-flow standby mode.

Advantages of this system:

- Reduced load on engine

- Improved fuel efficiency

- Enhanced oil cooling

- Reduced internal leakage

- Reduced hydraulic noise levels

- Less strain on hoses and seals

Pressure for the entire system is established by the function requiring the highest pressure. As demand lessens, so does hydraulic pump pressure and engine power requirements.

Other hydraulic system advantages include:

- Mechanical-controlled valves

- Hydraulic steering for effortless operation

- Hydraulic wet-disc brakes that provide an excellent brake performance

- Three-point hitch with increased lift capacity that can handle even the heaviest implements

High-capacity hydraulic pump

The hydraulic pump is located close to the hitch valve and selective control valves, allowing:

- Fewer and shorter lines

- Quick system response times

- Minimized energy losses

Essential services have priority

The priority valve ensures, even at low idle engine speed, full power to the essential services like:

- Steering

- Brakes

- Hydraulic trailer brakes, if equipped

Hydraulic and transmission systems are functionally separate; however, both systems utilize a common reservoir for easy serviceability.

Oil takeout capacity with/without additional tank

With PFC hydraulic system, an extra 12-L (3.2-gal.) oil reservoir is available to increase the oil withdrawal capacity of the hydraulic system. This permanently allows the optimum oil level of all drive components with advantages for durability and efficiency.

Intelligent Power Management (IPM) for transport and PTO applications

The Intelligent Power Management feature for 6RC Tractors is used for many typical farming operations that use the rear power take-off (PTO) in high-power applications, or when the tractor is used as a transport vehicle. Producers looking for more power in non-stationary PTO and transport applications will take full advantage of this feature.

In high PTO power applications or where heavy trailers, carts, or implements are moved to and from various locations, this feature provides significant additional capabilities:

- Improved productivity

- Quicker acceleration

- Better holding of desired transport speeds

Tractor applications

PTO application

PTO application Transport application

Transport applicationHow it works

There are specific operating parameters when the Intelligent Power Management system functions to boost engine power. It is the intelligent part of the system that provides seamless operation while adjusting the engine horsepower, depending on how the tractor is being used.

For engine-horsepower boost activation, the tractor must already be running an application that is using the full power capability of the tractor.

PTO activation

PTO application

PTO application

Operational conditions for activation:

- Power must be sensed going through the PTO drive clutch by the tractor electronic systems.

- The tractor must be moving faster than 1 km/h (0.62 mph). Then gradual stepless performance ramp up starts. At 2,5 km/h (1.6 mph) full IPM power is available.

- Engine rpm at least 70 percent of rated speed

NOTE: If the tractor is equipped with a front PTO, additional Intelligent Power Management power will transfer through the front PTO. However, Intelligent Power Management activation is only sensed through the rear PTO. Adequate load must be sensed on the rear PTO in order for Intelligent Power Management to activate.

Transport activation

Function in transport mode

Function in transport mode

When in transport applications, the power transition is smooth. The engine responds seamlessly as load changes, such as when going up and down hills.

Operational conditions for activation:

- Engine rpm at least 70 percent of rated speed

- Tractor operation speed 15 km/h (9.3 mph), gradual stepless performance ramp up starts

- At 20km/h (12.4 mph), increased rated engine performance available

Power boost levels other than at rated rpm

Some operators will run the tractor at full loads and/or run transmissions in auto mode in transport. This means the engine most likely will not be operating at rated rpm. As the engine is loaded, it will eventually drop off of rated rpm and use the power bulge as rpm slows. This is the way every John Deere PowerTech™ Plus engine operates when loaded to maximum power and torque.

Intelligent Power Management provides additional engine horsepower from rated engine speed down to approximately 1300 rpm.

Horsepower levels are increased above base equipment power bulge values.

If the PTO is engaged and the engine rpm stays near the rated speed of 2100 rpm, the full additional power potential for the tractor model will be available for use to handle additional load from the implement or changing terrain.

If the PTO is not in use and in transport operation and the rpm has dropped off of rated speed, usable additional power boost of Intelligent Power Management will taper off as rpm decreases.

Tractor compatibility with additional power

Intelligent Power Management has been thoroughly tested by John Deere engineers to be compatible with the tractor's base equipment with no impact to reliability. John Deere provides Intelligent Power Management as opposed to unapproved aftermarket devices that boost power without regard to engine, transmission, axles, drawbar, or hitch capability.

This feature provides optimal utilization of tractor components. For example, with PTO operation, power goes through the axles to move the tractor along the ground and turn the PTO shaft and implement.

Adding power to both of these systems does not overload either one individually. At transport speeds, drivetrain torque load decreases significantly from levels seen at low field speeds. Adding power at transport does not overload transmissions or axles.

Aftermarket devices are not selective when power increases are available. Great amounts of power increase are promised with these devices. Large power changes are not compatible with the tractor's base equipment.

NOTE: The tractor's base equipment changes as power increases. Larger parts, like hitches, drawbars, tire size, drivetrain components, axle diameters, and engine calibrations for emission performance and cooling, ensure durability of the total vehicle as power increases. Operating outside of the design capabilities of the tractor's base equipment will have an impact on durability and reliability.